WAGO’s Remote I/O: The Winning Hand in Industrial Automation

August 8, 2024

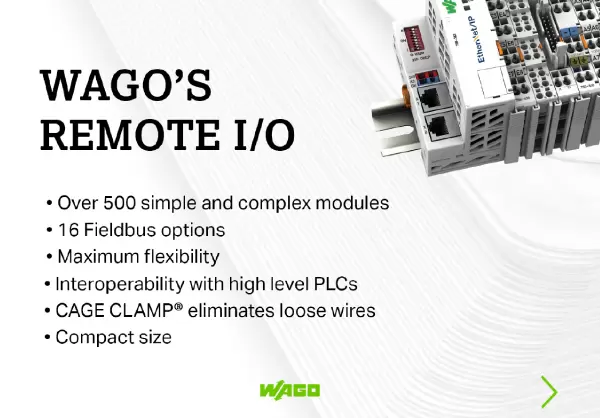

WAGO’s 750/753 Series Remote I/O system provides the confidence to go all-in on your automation application. Boasting 16 fieldbus options and interoperability with higher level PLCs, these modules offer the most flexible, modular, and compact platform for stand-alone or distributed automation. Choose from over 500 simple and complex modules that allow for easy data acquisition from almost any signal. Cost-effective system upgrades can be made for energy monitoring, IO-Link masters, and proportional valve control, just to name a few examples.

Whether it’s a need for digital or analog, WAGO ensures that you will get only the I/O needed for your application within a small, compact footprint. Thanks to our patented CAGE CLAMP® technology, and by using their extensive range of marking systems, these modules are easy to wire and provide a vibration-proof, maintenance-free connection.

About WAGO:

Innovation is at the heart of everything they do at WAGO. From their pioneering CAGE CLAMP® spring pressure connection technology to their extensive range of Interconnect, Interface and Automation solutions, such as the fieldbus independent I/O-SYSTEM, their customers count on the unconditional performance and reliability of their products to ensure the safe, efficient operation of their systems every time.

More Information

For additional information, visit www.wago.ca

Related Story

WAGO IoT Box: Ready-to-Use Solutions for Industry 4.0

Integrating machines and systems into the “Internet of Things” ” is incredibly simple with WAGO’s IoT Box. The complete system is ready for immediate use and offers all the functions required for digitalization from signal acquisition to cloud connectivity. The IoT Box was designed as a plug-and-play device – no hardware engineering is needed. Collected data is transferred to the desired IoT application with just a few parameter settings.