Vention Unveils Click & Customize Robotic Work Cells — Fast-Deploy Machine Tending & Welding Solutions to Address Manufacturing’s Labour Crisis

March 13, 2025

- Vention’s Click & Customize family of pre-engineered robotic work cells delivers the fast ROI of a turnkey product with the customized performance manufacturers need

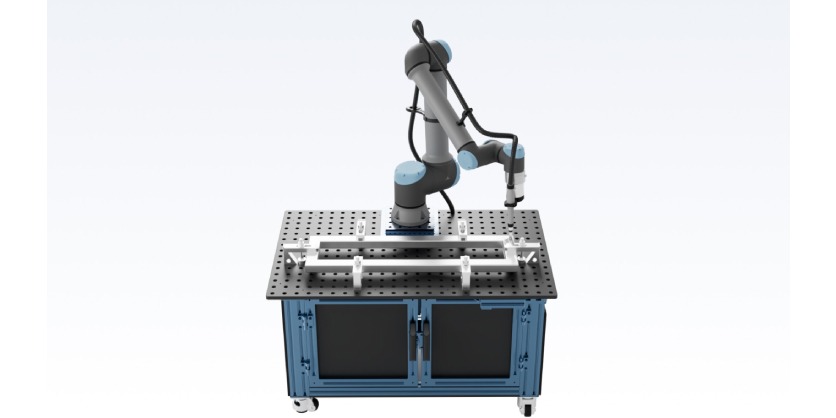

- The Machine Tending Solution is Vention’s second Click & Customize product, offering configurable automated CNC tending with two starter bases and other options

- Released in January, the Click & Customize Robotic Welding Solution enables job shops to quickly build their own welding cell, starting with one of six starter designs

- Built for speed and flexibility, these work cells streamline automation and come with end-to-end service and support to ensure successful implementation

- Both Click & Customize robotic work cells will be on display in Vention’s booth during Automate 2025, North America’s largest automation event in May (Detroit), and Fabtech 2025, the leading metal fabrication event in September (Chicago)

Vention, creator of the world’s only full-stack software and hardware automation platform, is expanding its portfolio with the launch of a Click & Customize robotic work cell family — starting with machine tending and welding solutions designed to help manufacturers boost productivity amid the skilled worker shortage.

These pre-engineered solutions are ready to be customized with Vention’s free drag-and-drop MachineBuilder™ software and can be deployed in days.

Manufacturers and machine shops are struggling with workforce shortages, making it difficult to hire and retain skilled workers. More than 20% of manufacturing plants cited insufficient labor as a key reason they were not at full production, according to the U.S. Census Bureau’s Quarterly Survey of Plant Capacity Utilization (QSPC). Vention’s new work cells provide a fast and lasting solution that enhances productivity and safety while ensuring consistent quality.

“Machine shops are looking for practical, accessible automation solutions that don’t require massive upfront investments or complex integration,” said Etienne Lacroix, Founder and CEO of Vention. “Vention customers have successfully used our platform for machine tending and welding for years. With our new easy-to-configure machine tending and welding cells, businesses can now automate even faster and stay competitive.”

Machine Tending, On the Job in Less than Two Weeks

Designed for manufacturers and machine shops, Vention’s Click & Customize Machine Tending Solution automates the loading and unloading of material and parts from CNC machines, allowing operators to focus on higher-value tasks. Unlike rigid turnkey systems, this solution balances affordability, speed, and configurability—providing a compelling alternative to costly custom automation. Users can select from various base models and robot arm styles from ABB, FANUC, and Universal Robots. Vention also offers a wide variety of grippers and other end-of-arm tools.

Click & Customize Welding, for Quick ROI

Designed to streamline MIG welding processes, the company’s modular welding cells combine premium Vention equipment with industry-leading hardware and software, enabling businesses to automate with precision and efficiency. Vention’s new welding system enhances weld quality, improves deposition rates, and increases arc-on time—all while addressing the labor gap in skilled welding. According to the American Welding Society (AWS), more than 320,000 new welding professionals will be required by 2029.

More Information

Ready to automate? Click & Customize work cells ship in as little as 10 days. Get started today

Related Story

Vention Introduces AI, Making Adoption of Automation Easier

Vention has been on a mission to democratize automation since 2016. Etienne Lacroix, Founder and CEO, realized he could leverage software and technology to productize automation, making it more accessible to everyone. While working as an engineer and integrating systems for manufacturers, he noticed added costs and time delays occurred when automation was approached on a project-by-project basis. He saw what he calls ‘orphaned machines or code,’ and distinct variances between machines, so he started the company to address this discord.