Universal Robots Introduces PolyScope X, a New Software Platform

July 20, 2023

At the automatica 2023 show in Munich, Universal Robots, the Danish manufacturer of collaborative robots (cobots), presented a new brand-new, innovative software platform specifically developed for machine tending tasks. The name is PolyScope X and through a new, customizable user interface, it will add new levels of flexibility to high mix, low volume machine tending automation.

With PolyScope X, machine shop operators can achieve changeover times of less than 10 minutes – far below what is possible today with any other software.

This will empower users to run more batches in a day and to run them in a more strategic and flexible way. PolyScope X is therefore ideal for high-mix, low volume production and is introduced at a time when manufacturers all over the world are looking for increased flexibility to handle shifting and increasingly diverse orders.

At the same time, PolyScope X introduces a powerful reworked programming experience and toolset. This enables integrators and OEM partners to structure their program code into operations that can be reused throughout the program, making each operation simpler to understand, maintain and troubleshoot.

PolyScope X is a landmark development in machine tending automation. The simplicity of the user interface and the much faster changeover times will provide manufacturers with a whole new set of possibilities for how to automate their machine tending tasks and it will allow them to break some of the barriers that are holding them back today. I wouldn’t hesitate to call it a gamechanger for the industry, especially for those who have a high-mix, low-volume production.

Anders Billesø Beck, Universal Robot’s Vice President for Strategy & Innovation.

Built and developed with customers and partners

Throughout the process of developing PolyScope X, the UR team has involved customers and partners. A prototype of the software was shown at IMTS in 2022 and together with beta-testers this has provided valuable feedback for the team.

“PolyScope X is a perfect example of how we approach innovation at Universal Robots,” says Beck. “We want to include our partners and end-customers right from the start, making sure we understand the full scope of the challenges our customers are facing. For me, this is an essential part of creating this new product and we are confident as a result that it will help our customers to grow and reach their full potential.”

To begin with, PolyScope X for machine tending is available in Germany, United Kingdom.

More Information

Related Story

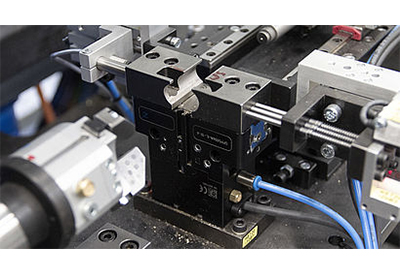

Universal Robots and SICK Announce Innovative New Safety Solution

There is a long history of successful collaboration between Universal Robots and SICK. Now the two companies have come together to address the need for additional safety measures in certain collaborative human-robot applications. The new safety solution will be demonstrated to customers for the first time at this week’s Automatica in Munich, Germany.