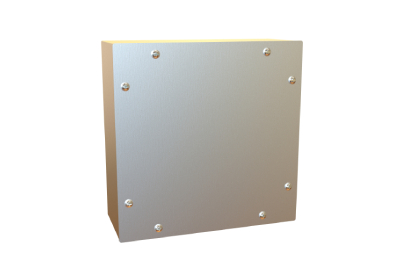

Type 4X Stainless Steel Junction Box C4XSC Series from Hammond Manufacturing

October 3, 2022

Application

- •Designed for use as a wiring box, junction box, terminal or pull box in indoor or outdoor applications where subject to hose down/precipitation or corrosion.

Standards

- •UL 508A Listed; Type 3, 4X, 12

- •cULus Listed per CSA C22.2 No 94; Type 3, 4X, 12

- •Complies with

- •NEMA Type 3, 4X and 12

- •IEC 60529, IP66

Construction

- •14 gauge 304 stainless steel body up to 12″x12″; 12 gauge body when 30″x30″ or larger

- •14 gauge 304 stainless steel cover up to 24″x24″; 10 gauge cover when 16″x16″ or larger

- •Smooth, continuously welded seams without knockouts, cutouts, or holes

- •Captivated stainless steel cover screws thread into sealed wells

- •Seamless poured-in place gasket

Finish

- •Enclosure and cover are unpainted, with a grained #4 finish.

To learn more about the nwe mild steel junction boxes from Hammond Manufacturing, click here