The NEW Model A58SB Absolute Bus Encoder

September 2, 2021

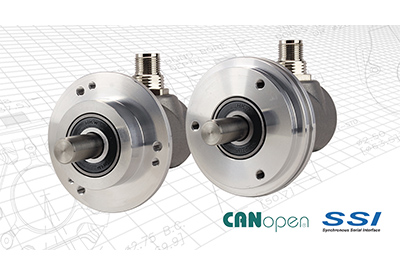

The Model A58SB Absolute Encoder is designed for harsh factory and plant floor environments. Heavy duty, rugged and reliable, this shaft absolute encoder is available in both single and multi-turn resolution. As an absolute encoder, it is especially suited to applications where an encoder needs to retain position information after power-off scenarios.

Absolute positioning

“In any type of machinery that has a time-consuming positioning routine – an example would be a satellite dish – an absolute encoder is ideal,” explains Sarah Walter, electrical engineer and EPC Sales Engineer. “With an absolute encoder, the controller has precise motion feedback about the position of the equipment, without needing to re-home during every start-up. Requiring the equipment to always re-home consumes valuable uptime. With absolute positioning, the controller ‘knows’ exactly where the machine is at all times, even after a power cycle.”

Model A58SB features

The A58SB Absolute Encoder offers:

- – Multi-turn resolution up to 43 bits

- – Up to 16 bits of single-turn resolution

- – SSI and CANopen communications

- – 58 mm diameter housing

- – Shaft in 6 mm or 10 mm

- – Synchro or clamping flange available

- – M12 axial or radial connector, in 5-pin (CANopen) or 8-pin (SSI)

- – Operating temperature range of -40° C to 85° C

- – Sealing rating of IP65 on the shaft, with the balance of the unit rated to IP67

- – Internal resistor option

- – Durable magnetic technology

- – Proven turns counting technology with no gears or batteries

- – Continuous digital position monitoring

- – Ability to retain absolute position after a power outage

- – Can be used in draw wire applications, with the EPC Model LCX

- – Can be used with a bracket and measuring wheel for a linear measurement solution.