The CIP Safety I/O Module for Industrial Applications from Balluff

July 4, 2022

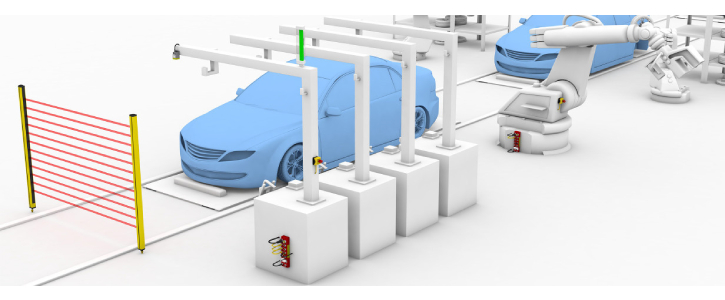

Automation needs safety and reliability. To ensure these for systems and operators, Balluff offers a comprehensive safe networking portfolio, that now includes their new CIP Safety I/O module.

SAFE Networking for the easy integration of industrial safety components

The module is a reliable solution for the safe connection of sensors and actuators to industrial controllers, even in harsh environments with influences such as dust, vibration, or liquid. The module, which can be mounted directly on the machine and has an IP67-certified housing, communicates with safety components via EtherNet/IP using the CIP Safety protocol. The combination of protocols enables the exchange of safety and standard control data as well as diagnostic information over a single Ethernet network.

Implementing safety functions in an industrial environment

In the field of functional safety technology, the CIP Safety I/O module from Balluff is a state-of-the-art solution that meets even the high demands of the industrial environment. It is extremely flexible and enables the connection of conventional and safety components. The combination of 12 safe inputs and 4 safe outputs predisposes the module for versatile use in safe automation technology, including automotive applications. The integrated memory key enables the module to be exchanged in less than one minute without special tools and renewed commissioning.

Features

- •Integration, acquisition, and control of safety components in safe applications up to SIL3, CAT4/PLe

- •Reliable processing of safe application data

- •Connection of single and dual channel safety devices

- •Suitable for the connection of safety and standard components

- •Digital bipolar outputs for drivers up to 2A per dual channel

- •Space-saving mounting on the machine

- •IP67 protection class, TÜV and ODVA certified

- •Self-monitoring and diagnostic LEDs

To learn more about the CIP Safety I/O Module from Balluff, download the Product Brief by clicking here or visit the Product Page by clicking here