The All-In-One Load Handling Power Combo Is Here!

October 7, 2022

The Donkey MAXO-MS-TVO15 (AGV)

The MS TVO15 (Donkey) is MAXOLUTION’s Canadian assembled and configured UL/CSA certified Autonomous Guided Vehicle (AGV). It has an impressive load capacity of 500 to 2000 Kg and draws its primary and continuous source of power from an inductive charging line (MOVITRANS®) concealed beneath the floor, which also serves as a navigation route in both dirty and wet environments.

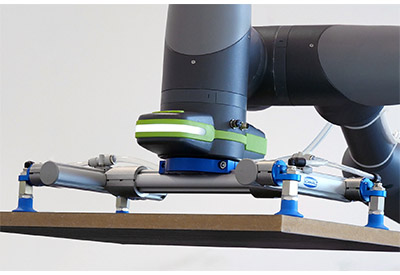

In instances where the AGVs needs to deviate from its primary power supply, the AGVs will then harvest its power from its built-in supercapacitors. Rated for 100,000 hours and > 500,000 cycles, the Donkey is built to be versatile and can be fitted with a variety of load handling appliances. In this example, the Donkey is integrated with an ultra-low, 16-inch profile, load handling device which utilizes the SEW-Eurodrive low voltage ECdrives® power rollers.

Electing to use ECdrives® low voltage power rollers in the design of the load handling device allowed our engineers to achieve a much-desired compact form factor with a low-profile design.

Watch this video to learn more about the Donkey and ECDrives Front View Connection

{videobox}3IsH8hnf3sU{/videobox}

MOVITRANS® Powering Options

MOVITRANS® is a sophisticated, no-contact inductive charging system that provides constant power to your AGVs. Due to it’s contactless, friction-free nature, MOVITRANS® requires zero maintenance and will accommodate a wide array of complex motion plans and can be supplied in multiple variants including; continuous charging loop, short recharging lands, or spot charges along the travel path.

Although the installation of MOVITRANS® requires minor alterations to your facility’s floor, the trade-off will work in your favour. Prior to installation, careful planning of your throughput process will be identified, and our MAXOLTUION® team of engineers will create a customized, highly efficient, motion plan using our sophisticated simulation software.

Watch this video to see Konrad explain the hidden (literally) benefits of MOVITRANS Contactless Charging System

{videobox}725uaQ8MhGA{/videobox}

MAXO-MS-TVO15 (Load Handling Device)

The MAXO-MS TVO15 AGV is programmed to connect with our unloading/loading station autonomously. The unloading/loading station is highly efficient and utilizes SEW-Eurodrive’s low voltage power rollers (ECDriveS®).

The two-part integrated loading station is a demonstration of our system solutions customization competencies. Each industry will have its own set of customization requirements for payload management, and our team of engineers are ready to solve any pain points within your facility’s motion plans. Our base loading stations are engineered for the modern era with an emphasis on compact form factor, low profile design, scalable modularity, and customization.

ECDrivesS® Power Rollers

ECDriveS® are low voltage power rollers, and idlers that available in PVC coated Stainless steel and the Galvanized steel. The roller conveyors are linked using a ribbed timing belt, or an O-ring belt. The 24-volt control heads are used to partition the conveyor’s system into multiple conveyor segments with multiple speed variations based on the sensors and the zone settings.

The control heads that regulate the speed and the speed zones are neatly hidden within the frame of the AGV, resulting in a compact form factor. The conveyor set can be divided into different speed zones and vary the speed of the load being transferred between each zone.

Watch this video to learn more about the low voltage power rollers, SEW-Eurodrive ECDrives

{videobox}Fq8gyEWfAuo{/videobox}

Team Max

Focus on growing your business and let us deal with the integration of your Autonomous load handling process.

The MAXOLUTION® All-in-one load handling combo is ready to be configured to your specifications. Connect with us and get ready to make the Shift to an intelligent, highly efficient, advanced manufacturing process that is industry 4.0 ready!

If you are interested in the All-in-one Load Handling Power Combo, just send us some quick information, and a representative from Team MAX will be in touch with your real soon! To connect, click here