Sustainable Automation with Pilz

June 26, 2023

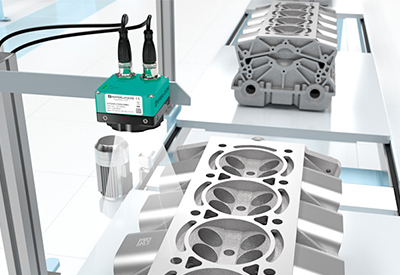

Automation technology helps manufacturing to be more economical and sparing on resources. Safe automation technology from Pilz supports their customers on the road to sustainable production. For a lower failure rate and increased availability and productivity. In short: for a long life for plant and machinery. That’s why Pilz has Industrial Security in its sights and provides support right through to a secure infrastructure in the production environment. Pilz offers its customers top-quality, energy-efficient and environmentally-friendly automation solutions – we always have the conservation of resources in our sights.

Product quality

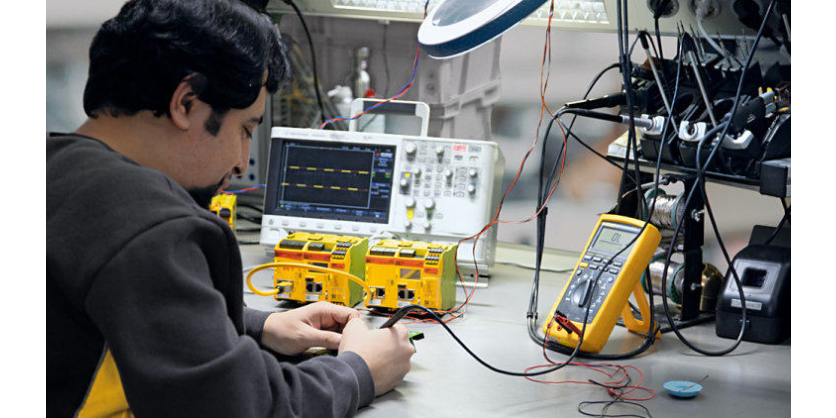

Quality is their product promise. Fewer returns mean that materials are not wasted. However, should a device be defective, we invite customers to return it to Pilz. Their employees can then check the extent to which the defective device can be re-used, either by repair or by exchanging individual components.

Return and disposal

Within the framework of the changes to the Electrical and Electronic Equipment Act (ElektroG) in 2021, Pilz offers their customers in Germany the option to return their products at the end of their lifecycle. The WEEE Directive 2012/19/EU (Waste of Electrical and Electronic Equipment) was adopted back in 2012. Among other things, this European directive deals with the labelling and return of electrical and electronic equipment via the manufacturer. The devices are disposed of or recycled professionally. Pilz’s international subsidiaries are registered locally and offer their customers a disposal solution. What’s more, they are continuously working on reducing pollutants in their products.

Further recycling measures:

- Waste products are recycled

- The recycling is prepared by separating the waste in our buildings.

- Packaging made of 100% recycled paper

- Film waste is minimised

Through these measures Pilz has already been able to increase the waste recycling rate to 95%!

Energy efficiency

Their aim is to develop environmentally-friendly products by using ecological materials and energy-saving technologies. The development department puts energy efficiency as a requirement of new products and technological advances, right at the start of the product lifecycle. In line with their corporate goals, each of their product generations is more efficient than its predecessor. This applies to all controllers, relays and sensors, as well as functions relating to actuator technology.

Three product examples:

Control systems PNOZmulti 2

Up to 80% less energy consumption than comparable products

Servo motors PMCtendo SZ

The servo motor are up to 20% more efficient than IE3

Safety switch PSENCode

Up to 30% less energy consumption than comparable products

Related Story

Susanne Kunschert: Safe Automation for Every Industry

Everyone knows of the risk due to security vulnerabilities, but who in the company should be responsible for questions relating to industrial security? IT experts or safety officers? To what extent do the normative changes affect me as an employer? If these knowledge gaps are not closed, questions on security will not be answered fully. So it’s clear that there’s a great need for information and further training to prepare a company and its specialist employees for the challenges of security.