SEW-EURODRIVE: New Inverters in the Modular Automation System

July 15, 2021

Since the beginning of the year, MOVITRAC advanced frequency inverters have completed the MOVI-C modular automation system. A MOVITRAC advanced not only saves space in your control cabinet, the high level of operating convenience also saves you time during startup and diagnostics. The power range of up to 315 kW also ensures flexibility and cost-effectiveness.

Space is a precious commodity, especially when you’re talking about control cabinets. Here, every centimeter that can be saved often counts. For this reason, SEW-EURODRIVE manufactures their new MOVITRAC advanced in a compact design. This all-rounder controls and monitors both synchronous and asynchronous AC motors, with and without encoders. Asynchronous motors with LSPM technology or synchronous and asynchronous linear motors are also no problem for this flexible inverter.

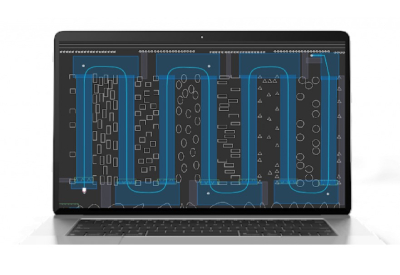

The MOVI-C modular automation system always offers you a complete solution for both centralized and decentralized installations: from inverter technology and drive technology to control technology – all from a single source.

You can also benefit from other advantages of MOVITRAC advanced, such as automatic startup of a motor with the electronic nameplate, simple unit replacement without an engineering PC or by using SEW-EURODRIVE’s preconfigured MOVIKIT software module.