The Most Sensitive and Durable Robot Hand Yet Created

February 11, 2025

When Google DeepMind wanted a robot hand for their latest project in AI machine learning, they turned to Shadow Robot. This latest creation isn’t just one of the most sensitive and dexterous robotic hands yet created, but it’s sufficiently robust to endure impacts that have destroyed previous designs.

Throughout human history, the role played by the capabilities of our hands cannot be understated. From prehistoric manhandling in the earliest tools to the precision demonstrated by modern-day surgeons, this dexterity is based on a limb that comprises 27 bones and over 30 muscles, guided by perhaps the most human of all organs: the brain.

This complexity makes a robotic hand highly challenging to control. In the world of robotics, there’s no higher level than the fine motor skills required to grasp and manipulate objects with precise speed and force.

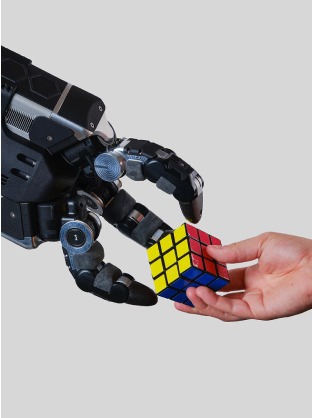

Meanwhile, companies like Google DeepMind are pushing the boundaries of artificial intelligence (AI). They are trying to understand what machines can learn to broaden the spectrum of practical possibilities and guide research. When Google DeepMind wanted to expand machine learning in the complex field of robotic hands, they came across a video of one such model learning how to complete a Rubik’s cube quickly.

Five DCX 16mm DC motors drive four joints on each of the fingers

A robot hand for the real world

It was Shadow Robot’s Shadow Hand, developed in partnership with OpenAI, that had impressed the Google DeepMind team. But this new project demanded something further still.

Rich Walker, Director of Shadow Robot, explains: “Google DeepMind wanted a robot hand capable of learning on real-world tasks. The hand would have to be the most dexterous and sensitive yet developed, but unlike other robots they’d tested, they needed it to survive even when subjected to the impacts involved in tough, practical tasks.”

Google DeepMind requested a high number of sensors to prioritise data collection, so Shadow Robot set about designing a hand with, as Rich puts it, “far more sensors than would be sensible in any other context”.

The goal was to create a robot hand with high dexterity, sensitivity, and robustness for real-world learning tasks without necessarily replicating the appearance of a human hand. To best achieve these needs, the design relies on three robust fingers and a hand around 50% larger than a human hand.

The result is DEX-EE, a robotic hand replete with high-speed sensor networks that provide rich data, including position, force, and inertial measurement. This is augmented with hundreds of channels of tactile sensing per finger, optimising pressure sensitivity to a dizzying level of magnitude, almost akin to a human hand.

Drive system innovation

To exercise fine control over the application of force and actuate the array of joints in the hand, Shadow Robot needed to rely on a highly capable drive system. A key innovation of DEX-EE is its unique design, which features a tendon-driven system utilising more than one motor per joint instead of a typical one-motor-per-joint approach.

maxon motors have a long manufacturing evolution behind them, and the pedigree they bring was crucial for the demands that would be placed on DEX-EE.

-Rich Walker, Director of Shadow Robot

With five motors driving four joints on each of the three fingers, this approach eliminates backlash, the ‘play’ that can occur when the direction of movement is reversed, to optimise controlled motion. With careful motor control, each joint can mimic zero joint torque, giving DEX-EE exquisitely sensitive movement control and the ability to handle delicate objects without risk.

To achieve the reliability and performance DEX-EE needed, Shadow Robot turned to its original drive system partner.

“maxon motors have a long manufacturing evolution behind them, and the pedigree they bring was crucial for the demands placed on DEX-EE,” says Rich. “This was especially the case for the rigours of real-world use that Google DeepMind was looking for.”

DEX-EE integrates 15 maxon DCX16 DC motors that achieve the high torque density necessary for the robotic hand to apply sufficient force across the tendons. This enables the hand to move with the required dynamism and strength for actions such as grasping and holding. At the same time, the motors had to be sufficiently compact to fit within the confines of each finger base.

The motor’s ironless winding also eliminates cogging, the relative jerkiness generated by traditional iron core designs. This helps achieve smooth, controlled motion, essential for DEX-EE to reach exacting levels of precision for the most delicate tasks. High tolerances in design and manufacture and premium materials ensure quiet operation and achieve high durability.

DEX-EE is thoroughly tested

The future of robotic hands

Over 1,000 hours of testing assured DEX-EE’s performance and reliability. This included simulating a process known as policy learning, where an AI explores how to effectively achieve a task by involving repeated random movements, which also cause mechanical stress. The Shadow Robot team also subjected DEX-EE to a high degree of impact and shock testing involving pistons and various tools.

Google DeepMind has already published research showcasing DEX-EE’s capabilities, including a video demonstrating the robotic hand’s ability to manipulate and plug in a connector within a confined workspace sufficiently enclosed around the robot hand to force impacts when the hand moves. This task highlights DEX-EE’s robustness, showing how it can withstand repeated collisions against the workspace walls while still completing the task.

“Google DeepMind is using DEX-EE as a research platform to study learning in real-world environments, and the hand’s robustness and sensitivity allow it to interact with objects in ways that would damage traditional robots,” says Rich.

DEX-EE is also now available as a research platform to wider organisations. While Shadow Robot’s creation has been developed to further our understanding of machine learning in everyday settings, Rich believes that complex robotic hand technology will become increasingly integrated into daily life in the future. As the technology becomes normalised, Shadow Robot’s Director says the ‘robot’ label could start to fade away as the devices become commonplace.

“In future, people working in robotics will develop devices that we use every day. At that stage, we won’t call it a ‘robot’ anymore. Then, our perceptions may no longer be as exciting as our current ideas of what a robot should be, but in reality, these devices could be far more useful to humanity than we had first imagined.”

Related Story

A New Docking System for Space Rendezvous

The European Space Agency (ESA) is working on a new system to enable easy docking between two spacecraft. maxon developed two special drive systems for this purpose.

Even though it’s been done many times before, the docking maneuver between two objects in space is always a delicate and potentially dangerous procedure. The speed is extremely high (about 28,000 km/h in case of the ISS), and corrections are difficult. For example, when the two objects are about to meet, maneuvering thrusters can no longer be used, since their exhaust plumes can cause damage. To prevent harm, cargo transporters are caught by a robotic arm installed in the International Space Station (ISS) and berthed manually. Manned spacecraft on the other hand dock directly in a computer-controlled process.