New Schmalz End-of-Arm Tooling Components from AutomationDirect

January 30, 2023

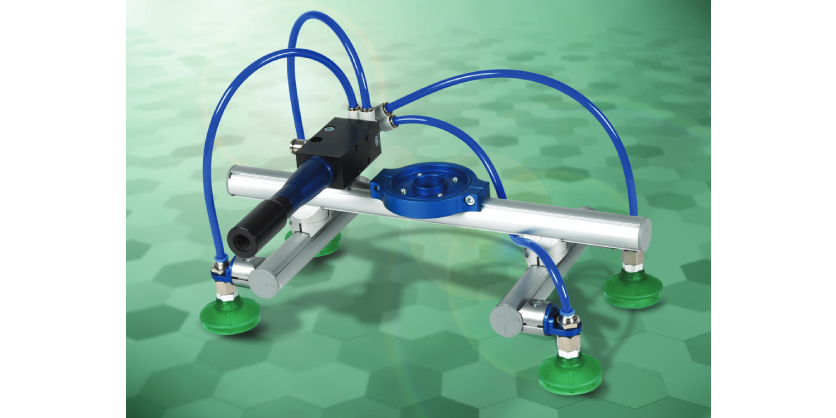

AutomationDirect now offers end-of-arm tooling components for robot arm vacuum pick-and-place applications. Components can be purchased individually or in kits that include everything needed to create a single-beam or dual-beam end-of-arm tool.

End-of-arm tooling components for vacuum pick-and-place systems are used to create tooling that connects to the end of a robot arm. These Schmalz end-of-arm tooling components can be purchased as a complete kit or be customized by purchasing components separately.

Kits are simple, save time and money, and include structural rails (which support optional internal vacuum), connectors, cup mounts, vacuum tubing, vacuum cups, fittings, a basic ejector, a flange for Universal robot, and a blank robot flange.

Simply cut the structural rails to the desired lengths, determine the location of the suction cups, assemble the unit, and add the robot interface flange for your brand of robot or drill your own using the included blank robot flange.

Schmalz end-of-arm tooling components start at $8.00 and kits start at $995.00. All Schamlz end-of-arm tooling components and kits come with a one-year warranty.

More Information

Learn more about Schmalz end-of-arm tooling components

Related Product

Schmalz Vacuum Products for Pneumatic Systems from AutomationDirect

AutomationDirect now offers a selection of pneumatic vacuum grippers and related parts from Schmalz, widely used in pick-and-place applications. Vacuum products are an efficient means of moving products large, small, and of varying sizes.

This lineup includes suction cups in a flat style up to 60mm in diameter made of Elastodur; bellowed style cups to 78mm made of Elastodur, silicone or nitrile rubber; vacuum ejectors that support a suction rate of up to 860 I/min.