Rockwell Automation Makes Widespread Implementation of CIP Security Possible with New Proxy Device

May 19, 2021

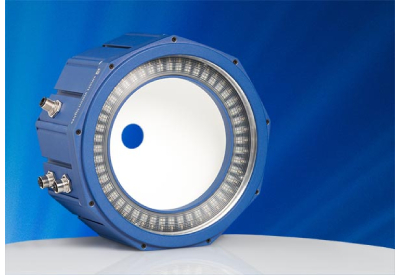

Industrial companies can now implement CIP Security expansively in their systems with the Allen-Bradley CIP Security Proxy. Traditionally, industrial networks had little-to-no security built into them. Now with a more Connected Enterprise, it is needed more than ever. The CIP Security Proxy allows users to implement CIP Security on most devices on their network, helping to protect plant operations – even with older systems.

The CIP Security Proxy helps to provide security to the entire network by working with EtherNet/IP-compliant devices. CIP Security is part of the defense in depth strategy, which can help defend against attacks where threat actors can remotely access a network and act maliciously. With the ability to provide CIP Security for a single device, a layer of security is added that can help protect the system.

Configuration for the proxy device can be achieved through FactoryTalk Policy Manager software and FactoryTalk system services. In addition, this device supports motion for Kinetix drives and offers a web server for viewing diagnostics. It allows for secure event generation syslog support and includes rotary switches for 192.168.1.xyz IP addressing. The proxy device also contains three one-gigabit EtherNet/IP ports and can operate in temperatures from -25° to +70° Celsius adding to the ease of use.

The proxy device allows users with non-CIP Security-embedded products to define and implement their unique migration roadmap to a CIP Security architecture. It also provides a path forward for non-CIP Security-capable products. By using this stand-alone, easier-to-use hardware solution, another step is being taken to obtain a secure network.