Rethink Robotics Launches Detachable Mobile Manipulator Robot at IMTS 2024

September 9, 2024

The Rethink Riser mobile manipulator robot (MMR) allows a single AMR to serve multiple stationary cobot applications.

Announcing a major relaunch and rebranding, Rethink Robotics returns to IMTS, unveiling a full portfolio of new robotics products, including seven Rethink Reacher cobots, its Rethink Ryder AMR line, and the Rethink Riser MMR. Combining a Rethink Ryder AMR with a Rethink Reacher cobot and a portable battery box allows mobile manipulation to be performed at new levels of efficiency.

The Rethink Reacher and Rethink Ryder, components of the Rethink Riser, each have their own battery packs, requiring separate charging. The Rethink Reacher offers an impressive 22-hour uptime. The Rethink Ryder can be charged in two ways: manually or wirelessly through inductive charging. Each Ryder comes equipped with three or four battery units based on its size. If higher uptime is required, customers can request up to two additional battery units per Ryder.

The control box that comes with Reacher is a compact and integrated unit designed to manage and control the robot’s operations. This control box houses the essential electronics, including the robot’s processor, power supply, and communication interfaces. It serves as the central hub for executing commands, processing sensor data, and coordinating the robot’s movements. The Rethink Riser’s control box is added as an attachment onto the Ryder so it can fully move along with it in combination with the Reacher cobot arm.

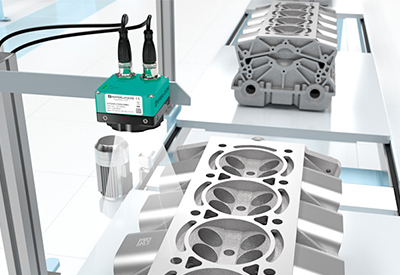

Rethink Riser is a perfect solution for intermittent pick-and-place operations and machine tending applications where cycle times are relatively long, making it difficult to justify the purchase of a dedicated cobot for each station. Rethink Riser allows flexible cobot redeployment, with each component achieving its maximum ROI potential.

About Rethink Robotics

Founded in 2008 by Rodney Brooks, Rethink Robotics transformed the robotics landscape. With groundbreaking robots like Baxter and Sawyer, the company redefined how people work, introducing a new era of safe, reliable, and flexible collaboration with robots in the workplace. Now reimagined, refined, and re-created with a fresh identity and renewed vision, Rethink Robotics is pioneering the future of collaborative robotics by introducing cutting-edge robotics into today’s workplaces.

Rethink Robotics designs, manufactures, and markets versatile, user-friendly robots that work alongside humans, liberating them from repetitive tasks while always prioritizing their safety. Rethink Robotics is dedicated to continuous improvement, with a strong focus on customer satisfaction. With its user-centric products and smooth implementation processes, Rethink Robotics ensures that businesses of all types can fully leverage advanced technology. Join Rethink Robotics as it redefines the future of work, one robot at a time.

More Information

Visit them at IMTS BOOTH #236203

Can’t attend the show in person? Watch the unveiling live

Related Story

Rethink Robotics Ushers in a New Era of Automation

— In celebration of its longtime role as an innovator and a partner in enhancing productivity and workplace safety, Rethink Robotics returns to IMTS with a major company relaunch and rebranding. With a fresh identity and renewed vision, Rethink Robotics continues to push the boundaries of innovation, seamlessly integrating advanced robotics into the workplace.