Liquid Level Sensing Using Reed Switch Technology

October 2, 2024

Liquid level sensors have been on the market for many years, used in industry sectors such as food and beverage, industrial, medical, printing, agriculture, automotive, and in white goods for leak detection or level measurement.

When measuring discrete levels of liquids, reed switch technology is simple, inexpensive and reliable.

celduc® offers liquid level sensors with reed switch reliability in numerous standard and custom configurations. This blog article introduce our know-how and range of level sensors.

How operate level sensors with reed switches ?

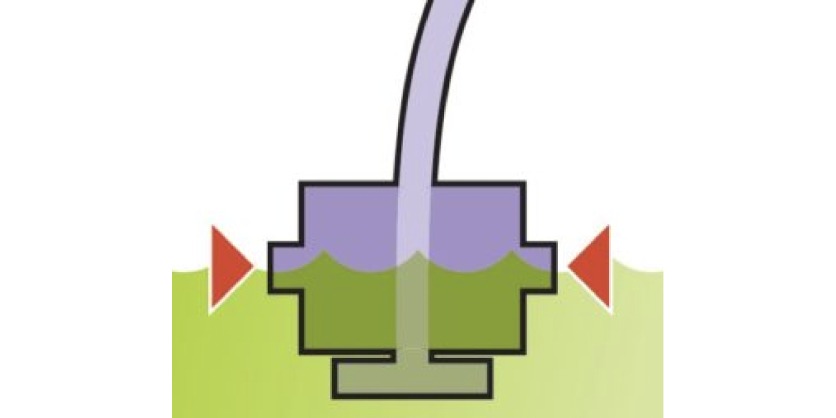

The principle involves a float fitted with one or more magnets which moves with the fluid and due to its magnetic field, activates one or more hermetically sealed Reed contacts.

The only moveable component within the sensor is the float itself, which rises and falls together with the level of the liquid. If the fluid reaches a defined limit level, the magnet within the float activates the Reed contact.

Liquid compatibilty

A sensor must be compatible with the fluids or materials to which it will be exposed. If the sensor will contact any caustic, corrosive or aggressive materials, it must be able to withstand them while maintaining proper functionality.

The type of liquid and the operating temperatures are key factors to determine the type of sensor to be used depending on its materials. Please review in our data-sheet the compatibility of our sensors with the fluid to be used as well as the working temperature.

Our level sensors are available in various types of plastics or stainless steel to cover different applications depending on the type of fluid.

Different contact types

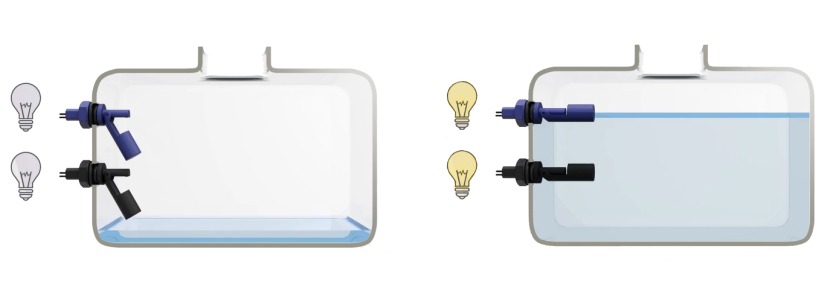

Our level sensors are available in different contact types:

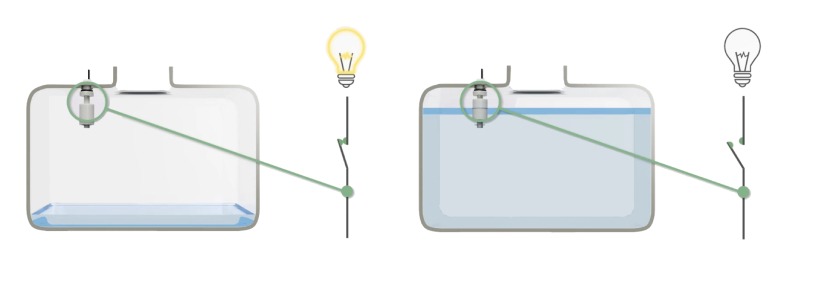

Form A Reed switch (or Normaly Open when there is no sensing object – NO)

It means that the circuit is open when the float is in “Normal” position, not floating. When the liquid level rises, the float moves with it, bringing the magnet up and into a position where it activates the Reed contact.

Working principles in case of horizontal mount level sensors:

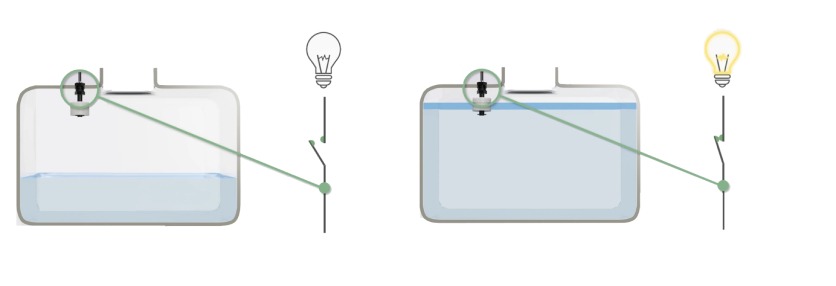

Working principles in case of vertical mount level sensors :

Form B Reed switch (or Normaly Closed when there is no sensing object – NC)

It means that the circuit is closed when the float is in “Normal” position, not floating. When the liquid level rises, the float moves with it, bringing the magnet up and into a position where it deactivates the Reed contact.

Working principles in case of vertical mount level sensors:

Some level sensors can also be mounted upside down, making normally open units into normally closed ones and vice-versa.

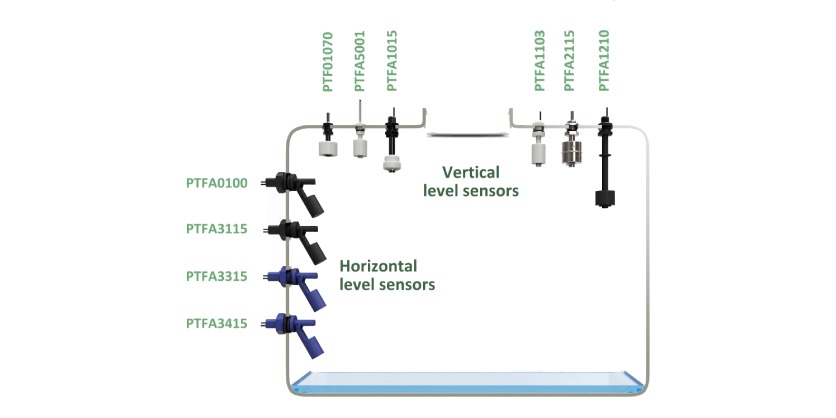

Different mounting configurations

There are usually several mounting options, the most common being horizontal/side mounting and vertical mounting, depending on the design and construction of the tank or container.

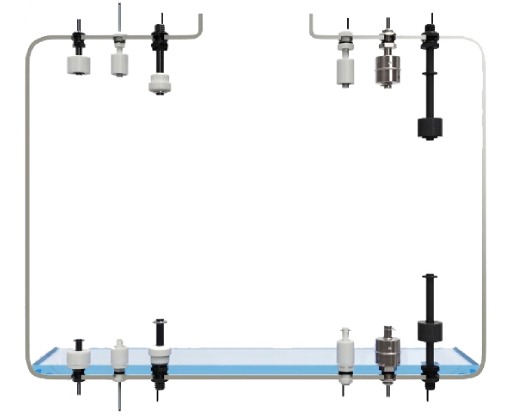

Vertical mounting

Vertical mount level sensors can be mounted vertically to the top or bottom of a tank or reservoir, whether you wish to detect a high or low level of liquid.

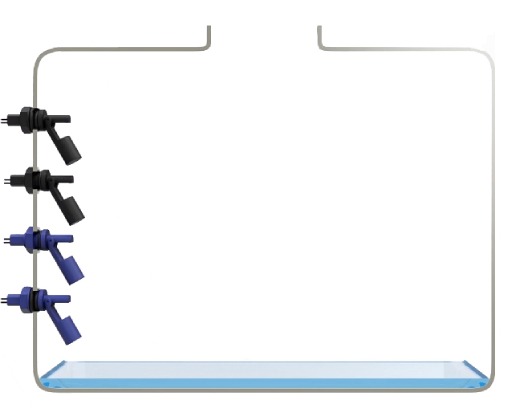

Horizontal mounting

Horizontal level sensors are side-mounted through a hermetically sealed hole on the side of a tank.

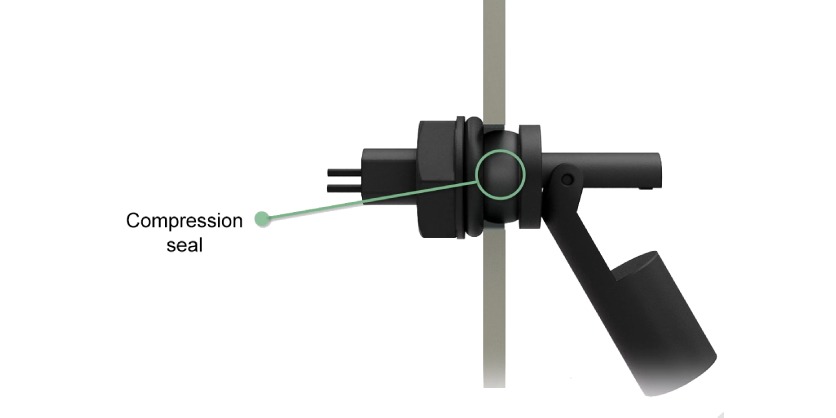

External mounting

External Mounting level sensors are designed to be installed externally. The use of a high grade compression seal avoids the need to access the inside of the tank and assembly can be carried out entirely from the outside.

celduc® models

Electrical specifications of our product range, depending on the model : Low Voltage Versus Max Voltage. (230VAC/350VDC).

Here are our standard level sensors

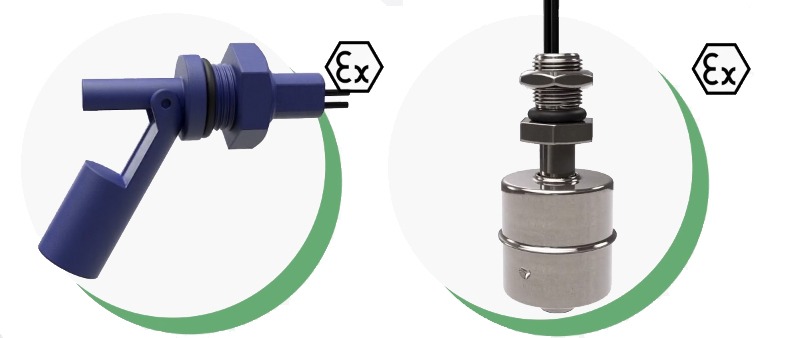

ATEX level sensors

celduc® relais is a certified ATEX product manufacturer under number INERIS 04ATEXQ406 and offers 2 models of level sensors that are ATEX certified (for explosive atmospheres).

Customer specific sensors : Do you have a custom requirement?

Our Salespeople will work with our R&D team to develop an optimal solution in response to your specifications: material, wire, cable, connector, specific accessory, etc.

We offer tailored solutions that are precisely aligned with the specific requirements of our customers. Our experts work closely with you to ensure the float switch is perfectly integrated into your application. We manage everything in-house

Here are some examples of customized solutions that we can develop for you : Two-level Reed switch sensor

- Different types of connections: wires, cable, connector… In different materials: PVC, PUR, Silicone, Teflon…

- Different mounting adapters: in plastic or metal.

Dimensions : G1, G3/4, G3/8, M16, M12.

Materials: PVC, PP, POM, STAINLESS STEEL, BRASS, ALUMINUM.

- Different contact types : NO (Normally Open), NC (Normally Closed), Change-over or Reed switch daisy chain …

- Depending on the fluid, other dimensions and/or materials are possible: PVC, Brass, Aluminum

- The level detected is defined by the circlip location: the position and material of the circlip can be adapted to your application.

- The material and size of the float depend on the temperature range, the nature and density of the fluid as well as the pressure : Materials: PVDC, PA, BNR, PVDF, POLYPROPYLENE, STAINLESS STEEL..

Advantages of level sensors

Level sensors with Reed switches offer several advantages that ensure user safety, repeatability, accuracy and operational reliability combined with low maintenance :

- The is only one moving part : the float

- Since a Reed switch is only activated by a magnetic field, there is no wear and tear.

- Because a Reed switch is hermetically sealed, there are no ingress protection issues.

- Dry contact with no power supply required allows for more flexibility of connected objects.

- Low cost solution, with no maintenance required.

Typical Applications

In all industrial processes that use tanks, silos or storage tanks, it is important to know the level of stored fluids/contents, or at least be able to detect significant levels (i.e. a full or empty tank). This is what level sensors are typically used for.

Here are some application examples :

- Water Level detection in coffee machines (the sensor position provides information which activates a pump to maintain the water level).

- Water purifiers (the sensor is used to detect the supply level).

- Medical equipment (water level in sterilizers)

- Oil tanks

- Air-conditioning, heaters and humidifiers (to detect the tank’s water level).

Discover the advantages of our level sensors and be convinced by their quality and performance. At celduc® relais, your satisfaction is our top priority.