PNO Specifies HARTING ix Industrial® as New PROFINET Interface

October 25, 2022

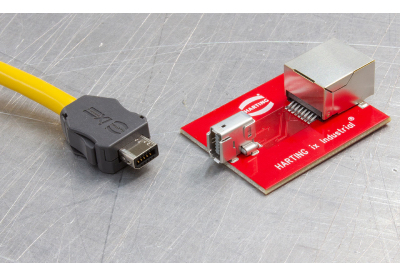

The new PNO guideline Profinet Cabling and Interconnection Technology – Guideline for PROFINET Version 5.0 specifies the ix Industrial® mating face as a new standard for Ethernet applications. The guideline was officially published on June 29, 2021, and provides PROFINET users with a reliable set of rules for industrial cabling. Thanks to the ix Industrial® PROFINET are benefitting from an Ethernet interface that is significantly more compact and more robust than previous RJ45 solutions – a path to the miniaturised future.

On June 29, 2021, the PROFINET User Organization (PNO) published the PROFINET Cabling and Interconnection Technology – Guideline for PROFINET Version 5.0 , a new set of rules for PROFINET-compliant cabling in industrial equipment, systems, and plants. The ix Industrial® mating face for Ethernet transmission represents a key new component in the SPC “Specific Passive Components” section.

Consequently, manufacturers of PROFINET-compliant devices are now able to develop more compact devices on a secure and reliable basis and thereby save valuable installation space in the control cabinet. Given the 70% smaller ix Industrial® device socket compared to known RJ45 connections, the number of ports can be doubled for the same device size or, conversely, a device can be designed that is significantly more compact.

In addition to the miniaturisation and space savings that will become increasingly vital in the future, the HARTING ix Industrial® interface offers device manufacturers and users one thing in particular: A high-performance, reliable, and industrial-grade connector paving the way to the future.

Core properties:

- •5.000 mating cycles

- •Robust metallic lock

- •THR shield contacts

- •360 degree shielding

- •Transmission up to 10Gbit/s

- •PoE/PoE+

- •70% smaller device socket

Benefits for PROFINET users and manufacturers:

- •Reliable contact in case of shock and vibration

- •Fewer contact interruptions

- •Acoustic feedback during insertion signals secure locking

- •Simple, convenient handling excludes accidental loosening

- •New miniaturisation options

- •Secure transmission

Depending on the application, users can choose between a straight or an angled cable outlet. This means that even tight spaces in control cabinets will not present any problems. Catering to demanding environments, the ix Industrial® interface will also be available in IP65/67 protected PushPull housings as from the autumn.

Measurement technology manufacturers established on the markets are reliably supporting the ix Industrial® standard with a wide range of measurement technology.

To see more product details about the HARTING ix Industrial® Ethernet Interface, click here