PLC and DCS Migration with MiBridge from Weidmüller

Migrate existing programmable logic controllers quickly and reliably without rewiring the field level

November 2, 2023

From the old to the new control system with minimised downtime

When industrial plants age, are no longer state of the art, or when support or spare parts availability is limited, a system update is required at the control level of a process plant. When replacing PLC and DCS systems, it is essential to avoid wiring errors and to keep the downtime of the plant as low as possible during the migration process. PLC or DCS migration with MiBridge from Weidmüller enables a secure exchange of the control level. Even adaptatiions or changes to the infrastructure can be performed simply and quickly without any need to intervene the field cabling.

Uniquely designed solution

The design permits your existing field wiring to remain in place and eliminates the need to wire-trace or ring-out.

Compatibility means flexibility

Universal conversion/migration system for the most important PLC old systems, to migrate to any new control system.

Minimal components maximise migration efficiency

Includes versions of card adaptors and cable types to accommodate flying leads or pre-wired field connections.

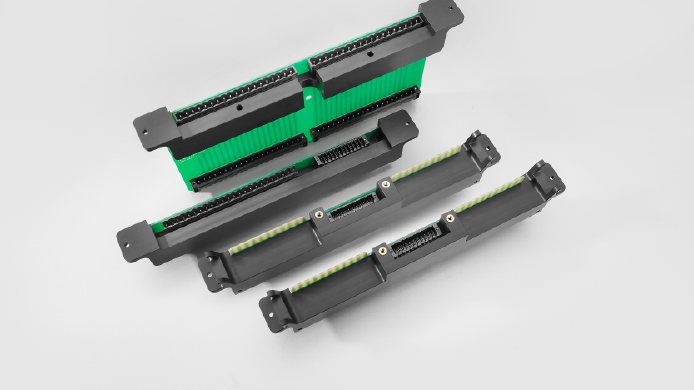

Space-saving bridging system

Convenient PLC and DCS migration within a few hours

PLC or DCS migration with our new migration interfaces does not require any additional space in the control cabinet. The rack system takes the place of the old controller and combines the connection level and the new controller into one compact unit. All connection components are easily accessible by simply folding down the upper level.

Your advantages

- No additional space required in the control cabinet

- Lower level: connection of the existing pre-assembled cables to the new adapters

- Upper level: Installation of the PLC / DCS components

- Pre-assembled interface cables connect the adapter cards with the new control system

- The correct retrofitting components for each PLC or DCS

Retrofitting made easy

The migration process – Weidmüller’s solutions at a glance

Step 1: The bridge takes the place oft he old control system so that no additional space is required in the panel.

Step 2: The front adapter is inserted into the rack system sot hate next step is to plug in the existing PLC or DCS cable connections and one end of the new pre-assembled cable.

Step 3: Lastly, the rail with the new PLC or DCS is positioned and the pre-assembled cable from the FAD is connected to the appropriate new I/O card

Scenario 1: PLC system was installed with PLC interface modules

In this case, only the PLC cable with proper connector and the PLC or DCS itself has to be replaced.

Scenario 2: Card solution (rack in place)

If in the new installation has enough space to add the rack of the new PLC or DCS without disassemble the old one. In this case, the adaptor card can be placed in the old PLC rack, while the new control system is located in a different cabinet/location. The adaptor card is provided with two connectors.

Scenario 3: Bridge solution

The Bridge solution does not require any additional space in the control cabinet. The adapter chassis and bridge take the place of the old controller and combine the connections from the field devices to the new controller into one compact unit.

More Information

Related Product

Open For the Future with u-OS from Weidmüller

u-OS is the new, open operating system from Weidmüller. It combines automation with the possibilities of the Industrial IoT in just one device and is suitable for edge computing solutions. It enables efficient data pre-processing and precise control directly to the machine. It is expandable and offers web-based system composition. This gives you access to the entire software landscape of Weidmüller and connected partner networks.