Pilz’s New Safety Solutions for Mobile Robot Applications

Dynamic zone switching for higher flexibility

November 16, 2023

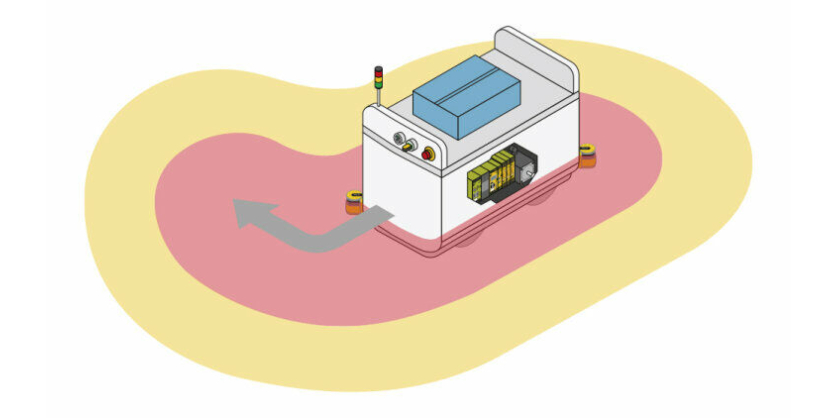

For freely navigating mobile platforms, Pilz offers a comprehensive safety solution in accordance with ISO 3691-4, consisting of the safe small controller PNOZmulti 2 with new functions for synchronisation monitoring, safety laser scanners PSENscan for productive area monitoring and various signal devices. The SecurityBridge firewall and PITmode for operating mode selection, consisting of PITreader with software block in the PNOZmulti, also offer greater safety by preventing unauthorised access.

Pilz’s safety solution offers robust components and a high level of flexibility due to open interfaces. Parameters for the software blocks in the PNOZmulti Configurator are easy to set and enable safe monitoring and dynamic zone switching when automated guided vehicle systems (AGVS) and mobile platforms (AMR) are used in your work environment.

Take advantage of Pilz’s experts’ know-how and let yourself be guided: from purchase of the mobile platform and the development of system concepts in the design phase, through to commissioning of your mobile applications. You will receive all the information you need on the key requirements for the safety of AGVS – including as part of appropriate training.

More Information

Related Product

New Safety Locking Devices from Pilz: PSENmlock Mini and PSENslock 2 For Higher Productivity – New, Small Gate Guards: Robust and Strong

When protecting guards, there are various factors to consider, depending on the application. For example, the type of safety gate, the respective installation situation and how it is used. With this in mind, Pilz is adding two new sensors to its portfolio of safety locking devices – PSENmlock mini for space-critical applications and PSENslock 2 with optimized hygienic design, as well as new versions with stainless steel components. Both sensors offer particular benefits for the packaging and pharmaceutical industry, and for the food and beverage sector. A high level of manipulation protection and added flexibility for the user are characteristics of both safety locking devices. This has a positive impact on productivity.