Piezo Technology Now Integrates Easily for Efficient and Precise Gas Handling

December 3, 2024

Medical technology and laboratory automation companies can now benefit from replacing proportional solenoid valves with piezo technology, reducing their energy consumption by up to 95%. Piezo technology also operates silently without any heat built up.

Up to now, it has not been possible to simply replace proportional solenoid valves since piezo technology needs voltages of up to 310 V and thus specific electronics. Now, however, there are simple solutions to create the needed voltage.

Why piezo valves need voltages of up to 310 V

The principle of piezo technology cannot be compared with a solenoid valve. The core element is the piezo ceramics. When the ceramics are electrically charged, it creates a polarization that causes the ceramic material to bend. The bending is proportional to the applied voltage and enables the flow rate or pressure to be regulated proportionally. The higher the voltage, the greater the flow rate. The current consumption curve is completely different than for a proportional solenoid valve, which has a permanently energized coil.

This is the only way to generate the magnetic field that lifts the armature away from the valve seat. A piezo valve, on the other hand, does not need to be constantly energized, since it behaves like a capacitor. An initial current is needed to charge the ceramic material once, then the current consumption drops to practically zero.

Controlling flow rate and pressure

The design of a piezo valve is simple, consisting of a housing with ports, with the nozzles injection molded into it. The gas flows in or out through these nozzles. There are one or two benders – made from the ceramic material – and above each of them a spring, which provides the return action.

A 2/2-way or 3/3-way valve is necessary, depending on whether the pressure or the flow rate is being controlled. The 2/2-way valve is an easy way of controlling a flow rate. It has one bender and two ports. The more voltage that is applied, the further the valve opens.

A 3/3-way valve has three ports and two benders. A complete pressure regulation system can be set up with this compact solution. There is one bender for pressurization (or increasing the pressure) and a second one for exhausting (or reducing the pressure). The third state is closed; this maintains the pressure. A 3/3-way valve easily controls pressure. Solenoid valves do not have a 3/3-way function like this.

Easily integrating piezo valves

Piezo valves do not operate using 12 V that solenoid valves use – piezo valves need special electronics. To make actuation much easier, Festo has developed piezo driver electronics in the shape of the new solution VAVE-P that has everything needed for piezo technology. The VAVE-P operates as normal with 12 to 24 V and generates the piezo voltage. It has everything necessary for the specific actuation of piezo valves: simple open-loop actuation electronics, 310 V voltage generation, and the 2-channel piezo driver stage with current limitation. The piezo driver electronics VAVE-P has

everything needed: open-loop actuation electronics, 310 V voltage generation, and 2-channel piezo driver stage with current limitation.

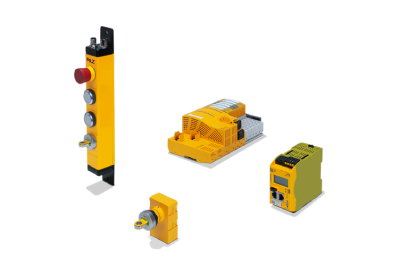

The VAVE-P, black units upper right, needs only 12 to 24 V to actuate the piezo valves.

The two-channel VAVE-P electronics makes it possible to actuate two valves for regulating the flow rate or a 3/3-way valve for regulating the pressure with separate actuation for pressurization and exhausting. The interface is always the same, two analog inputs and the flexible power supply of 12 to 24 volts. There is no easier way to replace a proportional solenoid valve.

Setting up a complete flow rate and pressure regulation system

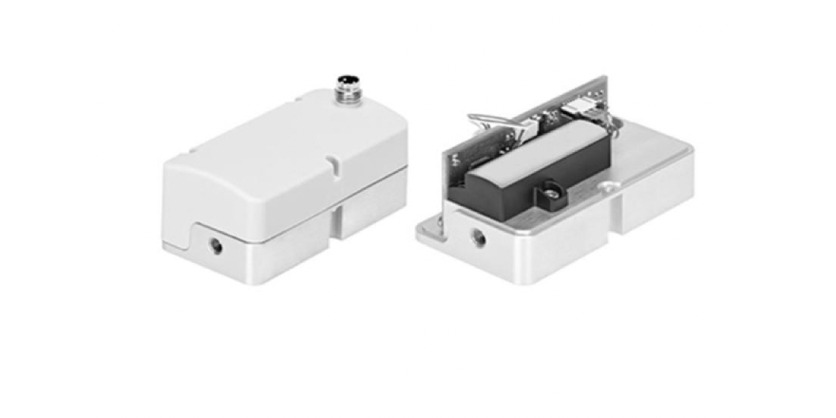

There are also solutions that come with all the components required for a complete flow rate or pressure regulation system. The compact flow control valve VEMD from Festo combines a piezo valve, flow sensor, and control electronics. The VEMD achieves an absolutely linear ratio of input voltage and output flow rate. The mass flow controller VEMD achievea an absolutely linear ratio of input voltage and output flow rate.

The counterpart for regulating pressure is the proportional pressure regulator VEAB with two piezo valves, in each case with one piezo bender for pressurization and one for exhausting. Then there are also the electronics and a pressure sensor, providing a complete closed-loop pressure control solution in the smallest installation space. The proportional pressure regulator VEAB provides a complete closed-loop pressure control solution in the smallest installation space.