Nidec Instruments Launches New Semiconductor Wafer Transfer Robot

September 6, 2023

Nidec Instruments Corporation a wholly owned subsidiary of Nidec corporation, has announced the release of its latest semiconductor wafer transfer robot.

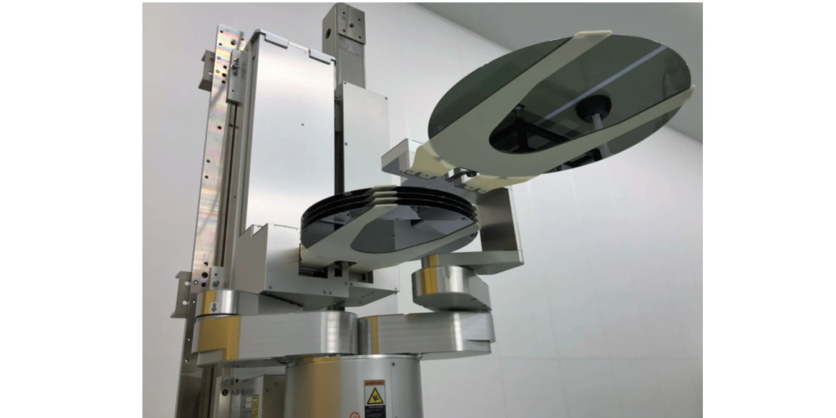

Nidec Instruments’ Latest Semiconductor Wafer Transfer Robot, SR7163 series

Despite a temporary slowdown in 2023, the global semiconductor market is expected to expand from 2024 after demand recovers in a wide variety of product groups such as memory logic and other IC products, and in the O-S-D (optoelectronics, sensor/actuator, and discrete semiconductor) segment. As the demand grows around the world for the construction of semiconductor factories with high production capacity, Nidec Instruments has developed the SR7163 series, a semiconductor wafer transfer robot to respond to its customers’ needs.

Among semiconductor manufacturing equipment, the SR7163 series is expected to be used in batch-type thermal treatment equipment and other machines in processes that require to transfer multiple substrates to a stage with a different slot pitch. A product that utilizes an arm-link mechanism to move a hand horizontally, the SR7163 series boasts a small minimum turning radius that can accommodate narrow pitches of up to the minimum limit of 6.5mm. In addition, with the use of a highly airtight link-type arm, the SR7163 series meets ISO14644-1’s Class-1 cleanliness requirements, which is the industry’s highest-level cleanliness.

As a member of the world’s leading comprehensive motor manufacturer, Nidec Instruments stays committed to offering revolutionary solutions that contribute to building a comfortable society.