New Sensors for the Safe Radar Sensor PSENradar

July 31, 2024

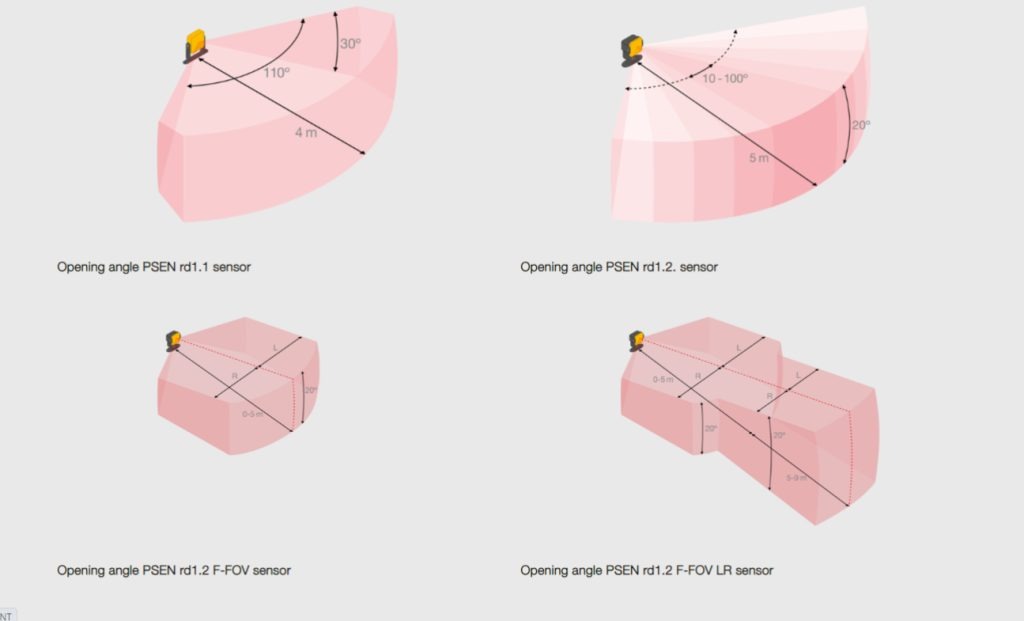

Two new radar sensors offer new possibilities in the field of safe protection zone monitoring: PSEN rd1.2 sensor F-FOV with a detection range of 0 to 5 meters and PSEN rd1.2 sensor F-FOV LR with a range of 0 to 9 meters. In addition to the symmetrical viewing angle, both sensors enable the configuration of asymmetrical as well as corridor-shaped viewing angles.

Safe radar sensor PSENradar

Safe protection zone monitoring in rugged application conditions

Safe radar sensors are used where optoelectronic sensors reach their limits: rugged environments, such as outdoors or in material processing for example, can be monitored safely using PSENradar. That’s because radar technology (FMCW: frequency modulated continuous wave) ensures high availability even where there are external influences such as dust, dirt, rain, light, sparks or vibrations.

The underlying volumetric monitoring with a frequency of 24 – 24.25 GHz can be used up to SIL 2, PL d and Category 3, which is often a requirement in robot applications. The complete solution also has additional interfaces such as Ethernet, Profisafe and FSoE, so making it easy to use the safety radar sensor in retrofit applications.

In conjunction with the configurable small controller PNOZmulti 2, the safe radar sensor PSENradar offers a safe, complete solution for protection zone monitoring – including conformity assessment for the plant or machine.

Safe radar sensor PSENradar – ideal for rugged environments

Insensitive to external influences such as dust, dirt, rain or light, the safe radar system is also ideal for use in particularly rugged application conditions.

Simple configuration with the PSENradar Configurator

For rapid commissioning, the sensors are easily selected and configured via the corresponding Configurator. Depending on the application, the safe radar sensor solution includes up to six radar sensors, one control unit and the configurable, safe small controller PNOZmulti 2.

The right protection zone can be defined for each sensor, depending on the size of the area to be monitored. This depends on the arrangement, installation height and inclination of the sensor. In addition to the protection zone, it is also possible to configure a warning zone. If a person violates the warning zone, this may be signalled by an optical signal, for example. This way, productivity of the plant can always be kept at a high level.

Download PSENradar Configurator

Benefits of the safe radar sensor PSENradar

- Insensitive to dust, dirt, rain, light, sparks, steam and vibrations

- High category Cat. 3 / PL d enables robotics applications to be safeguarded

- High flexibility thanks to optimised sensor alignment and individual protection zone configuration

- Safe complete solution with small controller PNOZmulti 2; open to retrofit applications thanks to additional interfaces

- Rear access protection to prevent the machine restarting when there are people in the danger zone

The right radar sensor for your application

Are you looking for the right radar system for your plant? The section below provides an overview of the radar sensors we have available.

In addition to the symmetrical viewing angle, both new sensors enable the configuration of asymmetrical as well as corridor-shaped viewing angles. You can now integrate the radar sensors even more flexibly into your production environment. With cramped conditions in particular, where machines are located within close proximity to one another or walkways run directly past machinery, you benefit from increased productivity. The PSEN rd1.2 F-FOV LR sensor also offers an operating range of up to 9 metres.

PSEN rd1.1 sensor | PSEN rd1.2. sensor | PSEN rd1.2 F-FOV sensor | PSEN rd1.2 F-FOV LR sensor | |

|---|---|---|---|---|

| Safety level | PL d, Cat. 2 | PL d, Cat. 3 | PL d, Cat. 3 | PL d, Cat. 3 |

| Operating range | 4 m | 5 m | 5 m | 9 m |

| Frequency | 24 GHz | 60 GHz | 60 GHz | 60 GHz |

| Field of vision | Symmetrical | Symmetrical | Symmetrical, asymmetrical, corridor-shaped | Symmetrical, asymmetrical, corridor-shaped |

| Opening angle | Wide opening angle: 110° horizontal, 30° vertical Narrow opening angle: 50° horizontal, 15° vertical | Horizontal (configurable in 10° steps): 10-100°, Vertical: 20° | Horizontal (configurable in 10° steps): 10° – 100°, Vertical: 20° | Horizontal (configurable in 10° steps): – up to 5m: 10°-100° opening angle – 5 to 9 m: 10° – 40° opening angle Vertical: 20° |

An overview of the different opening angles:

Analysis unit with USB, Profisafe and EtherCAT FSoE

In this portfolio you’ll also find the corresponding analysis units, compatible with the radar sensors. With the widest range of interfaces such as USB, Ethernet, ProfiSafe and EtherCAT FSoE, we always offer the right solution for the various fieldbus systems. So you can integrate the radar systems directly into your application. Together with the safe small controller PNOZmulti 2 as FSoE Master, you can easily implement safety-related networking with the safe radar system in the EtherCAT communication system as a one-cable solution – with minimum wiring effort.

The analysis units enable the configuration of up to 32 zone sets and therefore offer various options for integration in your application. With the integrated SD card, the new analysis unit also offers the option to save defined configurations, thus enabling the analysis unit to be easily swapped without the Configurator.

Protection zone monitoring with the safe radar sensor PSENradar

Radar sensors are used in a wide range of industries, from woodworking and metalworking to outdoor use. Safety-related functions covered by the safe radar system PSENradar include the safeguarding of danger zones and rear access protection.

While the safeguarding of danger zones brings the machine to a safe state as soon as someone enters, rear access protection prevents the machine restarting automatically if there are people still in the danger zone, in a maintenance situation for example.

Discover more about its use in practice

Safeguarding of danger zones and rear access protection

Robot in metalworking

The safe radar sensor is typically used in heavy industry, where welding sparks, swarf, dust, bright light and vibrations prevail, for example.

Whenever a robot cell is safeguarded, it is absolutely essential that rear access protection and a safe restart are guaranteed. For that, the robot application requires a high level of safety. The safe radar sensor PSEN rd1.2 enables protection zone monitoring up to Category PL d, Category 3.

Safe woodworking thanks to protection zone monitoring

When woodworking, including when sawing, it is often impossible to use optoelectronic sensors due to dust and airborne swarf.

In this case, safe protection zone monitoring comprising PSENradar and PNOZmulti 2 represents the optimum solution for detecting people within the danger zone. Various applications can be safeguarded simply thanks to the individual design of the protection zones.

Safeguard outdoor applications using radar sensors

Particularly outdoors, protection zones can be monitored safely thanks to radar sensors. For example, on a gantry crane or also on lifting devices. High temperature differences are at play here, as well as humidity due to rain, snow or fog.

The radar sensors ensure that there is nobody within the travel path. With an operating range of up to 9 m, large areas can also be safeguarded productively.

Safe radar sensors PSENradar Product Range

Assemble your safe radar sensor PSENradar yourself, with up to 6 sensors per control unit.

Accessories for Safe radar system

Here you’ll find suitable accessories for the Safe radar system

Related Story

Software PNOZmulti Configurator – What’s New in Version 11.4

The software tool PNOZmulti Configurator is used to configure the hardware of the safe small controllers PNOZmulti 2 and to create the safety circuit. The original configurable safety program is proven to be easy to use.