Introducing a New Generation of POSITAL Kit Encoders

December 11, 2023

POSITAL has announced a major upgrade to its family of 36 mm kit encoders for motion control applications. For these new devices, introduced as part of the company’s NEXTGEN initiative, upgrades include higher resolution and refined packaging that provides more compact form factors, better protection from solid particles and simpler installation procedures.

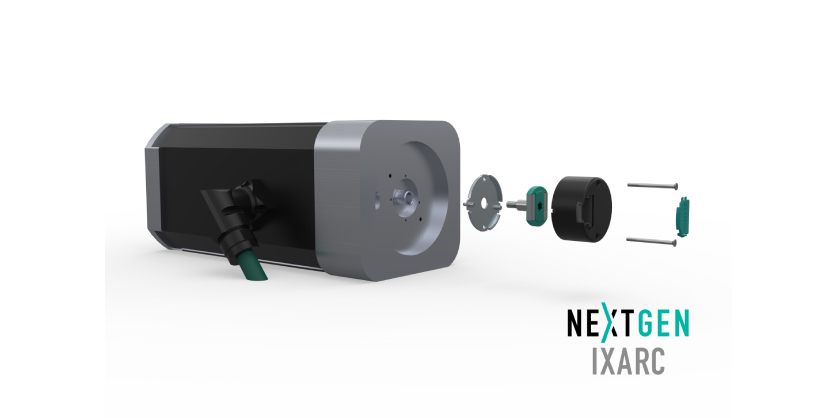

Kit (or modular) encoders are designed to be integrated into electric motors or other types of rotating machinery, providing position feedback for the control system. While sharing many characteristics with POSITAL’s stand-alone absolute encoders, kit encoders are stripped down designs without separate shafts or bearings. When installed in a motor, a permanent magnet array is attached directly to the motor’s shaft, while the measurement module would be attached to the motor’s housing. The result is a rugged, cost-effective assembly that provides precise, feedback on the shaft’s rotary position, enabling inexpensive BLDC or stepper motors to perform many of the functions of more costly servomotors. These devices have been used successfully in thousands of motor and robot installations.

A key innovation marking the new generation kit encoders has been the introduction of TMR (tunneling magneto resistance) technology for rotational position sensing. TMR sensors offer more precise measurement of magnetic field changes, lower temperature sensitivity and lower energy consumption than the Hall effect sensors they replace, with the result that the new kit encoders have higher resolution (18-bit) and more stable performance over a wide range of operating conditions.

For multiturn variants, a new ASIC and new-generation Wiegand sensors combine to provide a self-powered rotation counter. With this system, every rotation of the host machine’s shaft is accurately recorded in the encoder’s non-volatile memory – even if rotations occur when system power is not available. No backup batteries required!

The packaging or the new generation of POSITAL 36 mm diameter kit encoders has been redesigned to make them easier to install and to improve protection against dust and debris from machining operations. The protective cover is now 19.3 mm high, down from 23.4 mm in previous models, making it easier to fit these devices into tight spaces. To speed installation, the number of screws fastening the encoder package to the motor housing has been reduced from four to two. Mounting tabs used on earlier kit encoders to attach a protective cover have been eliminated, with the protective cover and measurement module integrated into a single unit. The cable clip is also sealed against dust and solid particles.

POSITAL kit encoders are available with SSI and BiSS-C communications interfaces.

About POSITAL

POSITAL is a supplier of advanced industrial position sensors used in a wide variety of motion control and safety systems. The company is also an innovator in product design and manufacturing processes and a pioneer of Industry 4.0 (Industrial Internet of Things/IIoT), offering customers the benefits of built-to-order products combined with the price advantages of mass-production. POSITAL is a member of the international FRABA group, whose history began in 1918, when its predecessor, Franz Baumgartner elektrische Apparate GmbH, was established in Cologne, Germany to manufacture relays.

Since then, the company has played a trendsetting role in the development of rotary encoders, inclinometers and other sensor products. POSITAL’s sister company, UBITO, specializes in the development and commercial applications of Wiegand technology, an exciting tool for event sensing and energy harvesting. POSITAL and UBITO have a global reach with offices in Europe, North America and Asia – and sales and distribution partners around the world.

More Information

Related Product

POSITAL Announces SSI Interfaces for its New Generation of Absolute Encoders

SSI (for Synchronous Serial Interface) is a widely used communications protocol for many types of sensors, including absolute encoders. SSI is a serial communications system that connects sensors directly to digital PLC’s or microcontrollers through point-to-point wiring systems based on RS-422 communications standards. This offers high transmission rates and can support connections over distances of up to 1200 meters. (Maximum baud rate will depend on the transmission distance.) SSI is supported by most major PLC manufacturers.