New Emerson Pneumatic Valves Provide Greater Automation Flexibility, Optimized Flow

July 3, 2024

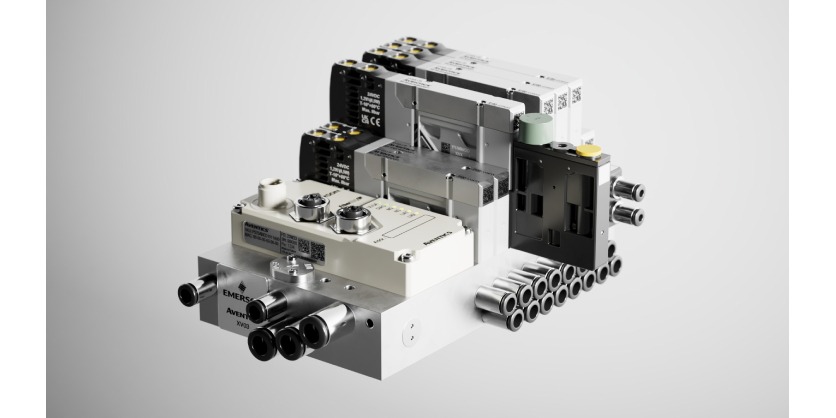

The AVENTICS XV valve series features multiple interoperable valve sizes and higher flow rates in a compact design

Emerson has launched its AVENTICS™ Series XV pneumatic valves. Series XV valves are designed with interoperability in mind to provide machine builders across multiple industries and factory automation applications with a flexible and cost-effective valve platform. The new valves are ideal for machine builders and end users that operate across the globe, with universal threads and other features that support regional standards and global availability.

Series XV valves provide higher flow rates in a compact valve package that enables more efficient and flexible pneumatic system performance for factory automation, automotive and tire, and food and packaging applications. This helps manufacturers boost productivity and allows them to offer products customized for specific markets and customer preferences.

“In all industries, manufacturers need high-performance technology that gives them the agility and flexibility to stay ahead of rapidly changing market demands,” said Wolf Gerecke, director of product marketing for Emerson’s machine automation business. “The new AVENTICS Series XV pneumatic valves deliver that performance with optimized flow, a wide range of valves and an extensive portfolio of accessories.”

Series XV valves include the XV03, providing flow volumes up to 350 liters per minute in normal conditions (NL/min), and the XV05, scheduled for release in October 2024, providing up to 880 NL/min.

All valves in the Series XV line use proven AVENTICS core technology and include metal threads, parallel wiring, aluminum base plates and compact dimensions to make it easier to integrate into production system designs.

Series XV valves use consistent interfaces and have wide connectivity from single wiring over parallel connections such as D-SUB connectors. They also support leading fieldbus protocols, including PROFINET®, Ethernet/IP, EtherCAT, Powerlink, Modbus TCP, IO-Link, AS-I, to simplify integration into machine control networks.

Series XV valves are also easy to commission. The AVENTICS online configurator supports system layout, providing useful information, while easy-to-understand system documentation in the design phase helps speed up machine development.

More Information

For more information about AVENTICS Series XV pneumatic valve specifications, features and resources, please visit https://www.emerson.com/en-us/catalog/aventics-xv03.

Related Story

New Emerson Pressure Valves Ensure Flexible, Accurate Control for High-Precision Manufacturing

Emerson has announced the new AVENTICSTM Series 625 Sentronic Proportional Pressure Control Valves. With a control deviation of less than 0.5%, the new valves are designed to deliver highly accurate, electronic proportional pressure control and provide the flexibility needed to support sophisticated pneumatic control engineering applications. Data acquisition software (DaS) software included with Series 625 Sentronic valves also make it possible to quickly startup, monitor and control valves directly on a PC.