MiR’s New Autonomous Mobile Robot Maximizes Efficiency in Logistics Operations

September 22, 2022

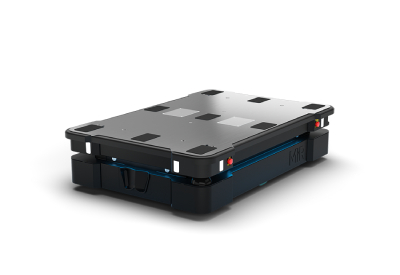

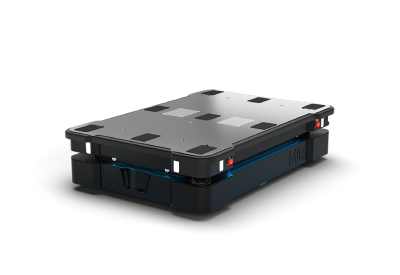

Advanced Motion & Controls Ltd. supplies autonomous mobile robots, or AMRs, manufactured by Mobile Intelligent Robots (MiR). The latest, most powerful AMR from this producer is the MiR1350, which offers a high payload that allows efficient transportation of pallets and heavy items. Its robust design ensures long life and easy serviceability.

Designed according to the latest safety standards, this unique solution by MiR navigates smoothly and efficiently within dynamic work environments.

Specially designed pallet lifters

The MiR1350 distinguishes itself with a payload of 1,350 kilograms, which helps users to maximize the efficiency of logistics operations. Its IP52 rating denotes a superior ability to withstand dust and liquid. Other key specifications: maximum speed of 1.2 meters per second; run time of nine hours and 50 minutes; length of 1.35 meters; and width of 91 centimeters.

The unit’s specially designed pallet lifters allow it to pick up, transport, and deliver pallets automatically. This makes the MiR1350 a safer alternative to standard pallet lifters and trucks, which often pose hazards in manufacturing plants. Unlike traditional pallet lifters, this AMR from Advanced Motion & Controls needs no operating crew, which optimizes pallet transport and allows workers to focus on more productive jobs.

The robot maneuvers around all kinds of obstacles, stopping immediately when an employee blocks its path. Its advanced technology and software enable autonomous navigation into the most efficient routes; the MiR1350 automatically redirects and reroutes when encountering obstacles, to prevent delays in material delivery.

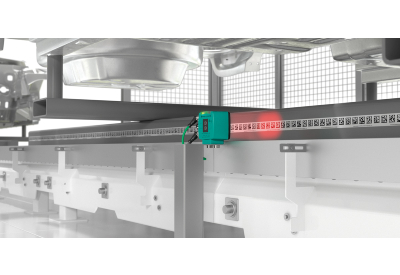

MiR has equipped the device with the most up-to-date laser-scanner technology, and its 360-degree vision also improves safety. The two three-dimensional front cameras allow the MiR1350 to see from 30 millimeters to two meters above the floor, while two sensors in each corner enable views of pallets and obstacles that are extremely low.

This user-friendly AMR gives users full control from the start, operated by the intuitive MiR Robot Interface through a Smartphone, tablet, or desktop. Users can program the MiR1350 based on previous applications and integrate it into an ERP system, which enables the creation of fully automated solutions.

For more information, contact Advanced Motion & Controls