MAXOLUTION® System Solutions from SEW-EURODRIVE

July 25, 2023

MAXOLUTION® System Solutions – Innovative and integral system solutions for your smart factory

Whether in production or logistics operations, MAXOLUTION® is synonymous with innovation in factory automation – across all industries and worldwide – helping you achieve your vision of an adaptable and resilient lean smart factory.

Under the MAXOLUTION® brand, SEW-EURODRIVE creates customized solutions for cutting-edge materials handling technology – from the shop floor through to IT. Our scalable portfolio includes mobile and autonomous plus track-guided transport and assistance systems. These are based on their own tried-and-tested modular technology system with its innovative hardware and software components.

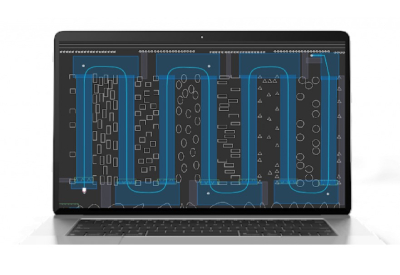

Smart services such as simulation/emulation together with virtual and augmented reality enhance the customized automation concepts, offering planning and process reliability along with maximum availability. Their partnership with their customers extends all the way from planning and startup to their 24/7 installed base service, which is available on site worldwide.

Thanks to their many years of experience and their global success, they know all about the requirements associated with automation, and they ensure futureproof and sustainable solutions for our customers.

More Information

Related Story

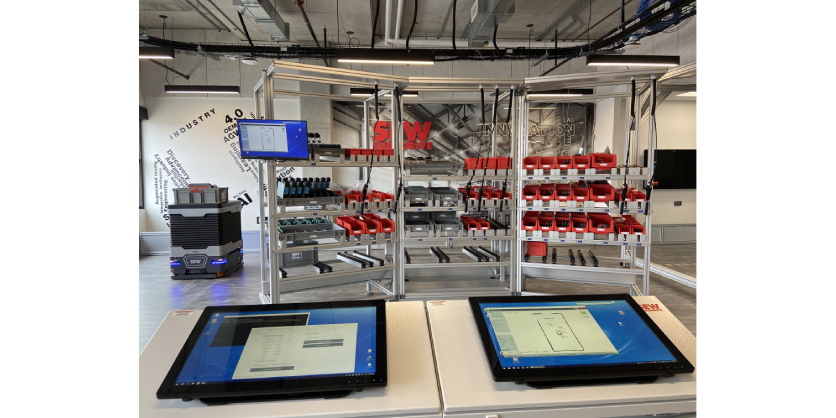

Introduction to SEW Eurodrive’s Innovation Lab

The introduction to SEW Eurodrive’s Innovation Lab was a big success. Automated guided vehicles (AGVs), collaborative robots (cobots), and augmented reality (AR) all had a turn in the spotlight, where the SEW Eurodrive professionals explained their technology and applications, and customers could ask questions to gain insight into how they could be integrated in their facilities. Seeing the technologies in the Innovation Lab demonstrated how small and medium enterprises (SMEs) can use these technologies to enhance their production processes and elevate their factories into the future.