Kinova Launches Link 6 Collaborative Robot

March 24, 2022

Montreal-based Kinova Robotics has announced the Link 6, a new generation industrial robot created from start to finish in North America, and designed for businesses looking to benefit from automation.

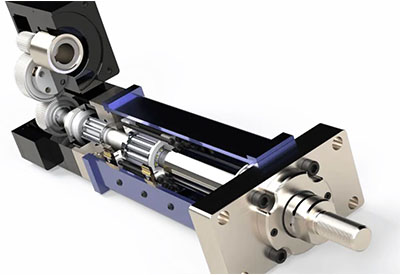

Kinova said Link 6 is Canada’s first industrial collaborative robot, featuring automation solutions to enable greater daily efficiency while also improving the quality and consistency of production results. Launch applications include pick-and-place, part assembly and machine tending, the company added. The Link 6 controller also includes the highest processing power and memory capacity on the market, which makes it ready to use with AI solutions in the future, while keeping the size of the controller compact. Kionva said the robot is developed and designed with any user in mind – from an experienced industrial integrator to an operator with no particular robotic skills.

“Our operating market is mainly in the United States, where robotics innovation is well established,” said Charles Deguire, CEO and founder of Kinova. “With the launch of Link 6, we also aim to lend a hand to the Canadian market. Collaborative robots such as Link 6 are an interesting and increasingly sought-after alternative to overcome the labor shortage, here and elsewhere. Kinova is here to help out growing companies, and automation is far more accessible than most people think!”

Watch this video to see the Link 6 in action

{videobox}https://vimeo.com/689520616{/videobox}

Features of the Link 6 include:

- •A user interface with visual programming and error handling;

- •Manual guidance capabilities;

- •Integration support through Kinova’s application engineering team;

- •Multi-purpose wrist for ease of use and increased efficiency, including a colored ring annunciator that shows the robot’s status and operating mode at a glance;

- •Built-in signal path and power supply for easy industrial connectivity;

- •Plug-ins that can be added to specific features for applications;

- •Native support for several industrial grippers;

- •Programming interface that makes it easier to implement developments in the field.

Kinova says the Link 6 robot is available now. For more details, visit this Kinova Robotics website.