Introducing the PE20 Robotiq Palletizing Solution

PE20. The Most Powerful Palletizer in the Robotiq Lineup

September 7, 2023

By Maude Desjardins

With a payload capacity of 18 kg (40 lb) and stacking heights of up to 2150 mm (84 in), this turnkey solution is designed to help businesses effectively scale future operations and achieve a quick return on their investment.

The PE20 is the third palletizing solution released by Robotiq for the packaging automation industry. Like its predecessors, the PE10 and AX10, the PE20 features a practical and highly compact design for easy integration and operation. Its narrow and frameless base help minimize its volume. This makes it one of the smallest and most adaptive footprints in the collaborative robot industry, saving companies from expensive production floor reorganization. Additionally, easy access to controllers and cables ensures hassle-free maintenance and troubleshooting.

This just released version of the PE Series incorporates changes to its base to offer enhanced performances and flexibility. The newly designed frame includes fork slots to effortlessly move the palletizer before anchoring it for production. The base edges of the PE20 are angled for smoother robot movements, particularly helpful when dealing with pallet patterns featuring overhanging boxes. Additionally, the PE20 is designed with photoelectric pallet sensors instead of mechanical sensors, making it even easier to handle overhang patterns.

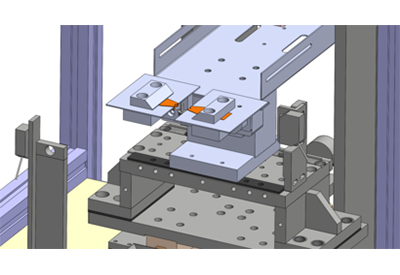

Equipped with the PowerPick20 vacuum gripper, the latest end effector innovation from Robotiq’s engineering team, the PE20 palletizing solution provides unmatched performance and versatility. The gripper has a high payload to weight ratio, allowing to optimize the net UR20 lift capacity to 18 kg (40 lb). PowerPick20 includes a dual-channel external controller. Enhanced control over the vacuum flow allows for optimizing multiple case pick performances as well as slipsheet management. The gripper kit includes multiple suction cups along with small and large brackets (as shown on the picture above) to accommodate different case sizes. And setting up the gripper is incredibly simple, requiring just an allen key. This eliminates the complexity and programming required with custom grippers.

PowerPick20 is the only standard gripper on the market that is designed specifically for palletizing applications using Universal Robot’s next generation arm, the UR20. Combined with its impressive lifting capacity, PowerPick20 is the top choice for users who seek performance, adaptability, and fast deployment time.

With regards to programming, Robotiq again hits the mark with its unmatched, user friendly and intuitive software, that actually requires ZERO programming. The solution features a visual interface and built-in modules that make setup simple, guiding the user through a sequence of easy steps. This optimization is the direct result of creating a standardized solution for palletizing applications.

Through standardization, Robotiq’s engineers have successfully eliminated countless complexities. Having the hardware parts pre-connected and already programmed within the software saves an immense amount of time and alleviates the risks of malfunction during installation. It also ensures seamless operation of all components when the solution is delivered to the customer. Time and efforts to define geometry, pallet positioning, and signal inputs in order to accurately manage the cell status, aren’t required. Unlike other software providers who do not offer hardware, choosing their solutions can lead to the need for custom programming and external expertise, resulting in extra costs and a lack of complete control over the palletizing solution.

But the Robotiq Palletizing Solution is so much more than the sum of the hardware and the software. The work that is relentlessly done in-house to handle and optimize robot trajectories based on countless pallet patterns, infeed options, palletized material types, and cycle times are additional reasons why the Robotiq Palletizing Solution is the most cost-effective palletizing solution on the market. You simply get more for your money.

More Information

PE20 Robotiq Palletizing Solution

Related Story

How to Create 75% Higher Throughput Palletizing with the Multipick by Robotiq

Collaborative robot palletizing can be the perfect tool for improving the productivity of your end-of-line process. Compared to manual palletizing, it is more efficient, consistent, and scalable. There is one thing that can still hold you back from getting the productivity you need: number of picks per minute.

For the vast majority of situations, the speed of an out-of-the-box robotic palletizing solution is more than sufficient. However, sometimes, you might need a higher throughput than the base solution can provide.