Innovation In Action: LM26 on Track After Swift 2023 Launch

June 19, 2024

At General Fusion, radical innovation and rapid iteration come together to deliver technology that will change our energy landscape. Fusion is the ultimate clean energy solution – it is the energy source that powers the sun and stars. Fusion is the process by which two light nuclei merge to form a heavier one, producing a massive amount of energy. General Fusion’s new fusion demonstration, Lawson Machine 26 (LM26), is designed to achieve two world-first breakthroughs using their Magnetized Target Fusion (MTF) technology in the next three years:

- By 2025, heating plasma to over 100 million degrees Celsius (10 keV) to achieve fusion conditions during compression; and

- By 2026, progressing toward scientific breakeven equivalent – when the amount of energy produced by the fusion reaction equals or exceeds the energy put in.

An example of building fast and building better, LM26 fast-tracks General Fusion’s timeline to commercialization by integrating their operational plasma injector with a simplified compression system. The race is on to commercialize fusion energy – and if you’ve visited their Canadian headquarters recently, you’ve likely seen their dynamic team simulating, designing, building, and iterating with unmatched speed.

LM26 was announced in August 2023, and within a few short weeks, their team pioneered a new method for creating solid lithium rings and began compressing them using a set of electromagnetic “theta pinch” coils. They achieved symmetrical compression after just five iterations, quickly completing the necessary testing to scale up. In the following months, they manufactured and assembled hundreds of parts for a critical new testbed, Prototype 0, which began operating in the fall. They built out a project supply chain and engaged new partners, kicking off the development of cutting-edge plasma diagnostics for LM26 with top experts from around the world.

This incredible progress at record pace puts us on track today to meet the transformational technical milestones they have set out to achieve in 2025 and 2026. These milestones are mission critical; achieving fusion conditions and scientific breakeven equivalent will validate General Fusion’s Magnetized Target Fusion technology – the only fusion approach that addresses the major barriers to commercialization – so that they can deliver clean, baseload power to the grid by the early to mid-2030s.

Let’s take a look back at the swift and successful launch of LM26, which has set the stage for a momentous year ahead at General Fusion.

Early results mark a successful project launch for LM26

Making fusion energy with MTF requires three ingredients: plasma, compression, and heating. To achieve fusion conditions, LM26’s plasmas will be formed in their world-class plasma injector, PI3, and compressed with a solid lithium liner, heating to over 100 million degrees Celsius (10 keV).

At the launch of LM26, the team at General Fusion successfully designed a test campaign that achieved symmetrical compression of a solid lithium ring in remarkable time.

From there, the team quickly advanced from compressing rings to compressing cylindrical tubes of solid lithium with a new testbed, Prototype 0.

“Our team adapted quickly to further develop the design we had successfully tested on the small ring compressor. We were able to design, build, and commission Prototype 0 over a short couple of months. It was a lot of work and a lot of fun!”

— DARREN ROSS, LEAD PROJECT ENGINEER, COIL DESIGN AND SUPPLY

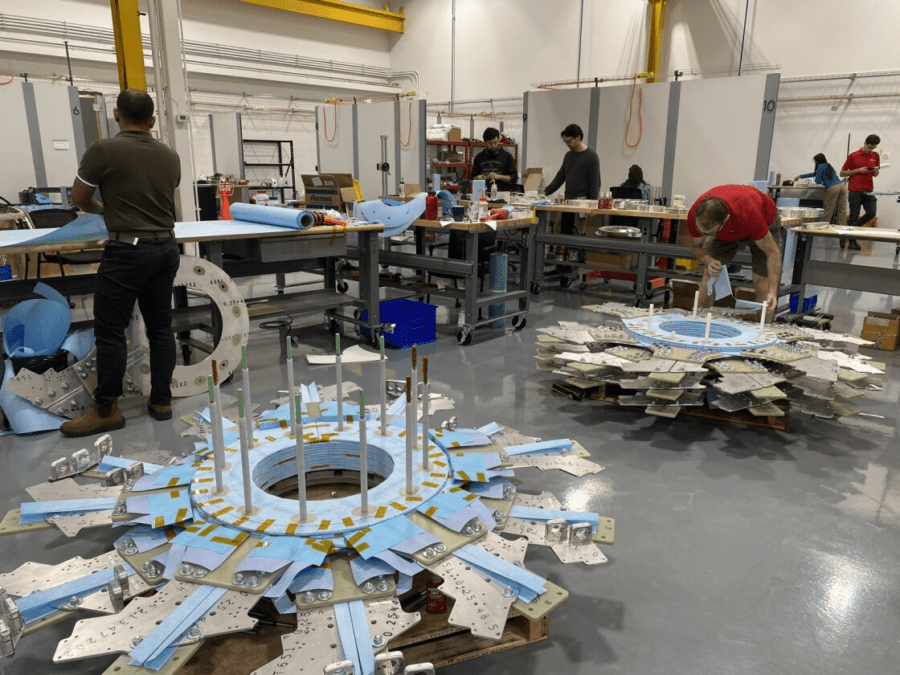

From their scientists to engineers, their accountants, and even their IT department, it was all hands on deck to complete the coil assembly for Prototype 0 and prepare for its operations.

A company-wide effort was behind the rapid assembly of Prototype 0.

Each run of this machine provides crucial data on collapse symmetry and stability to de-risk and inform the design of LM26’s full-scale compression system. General Fusion’s modeling team developed two methodologies to predict the performance of the Prototype 0 compressor, and their early measurements on the testbed align closely with the group’s predictions. This alignment between simulation and experiment gives their team a better understanding of how the full-scale system will perform to support their goals to achieve 10 keV and progress toward scientific breakeven equivalent.

“This is exactly why I love working at General Fusion. When operating these ground-breaking, never-been-done-before testbeds, the energy in the lab is exhilarating.”

— PIOTR FORYSINSKI, MANAGER, COMPRESSION SYSTEMS TESTING

Entrepreneurial spirit and rapid iteration skills on display

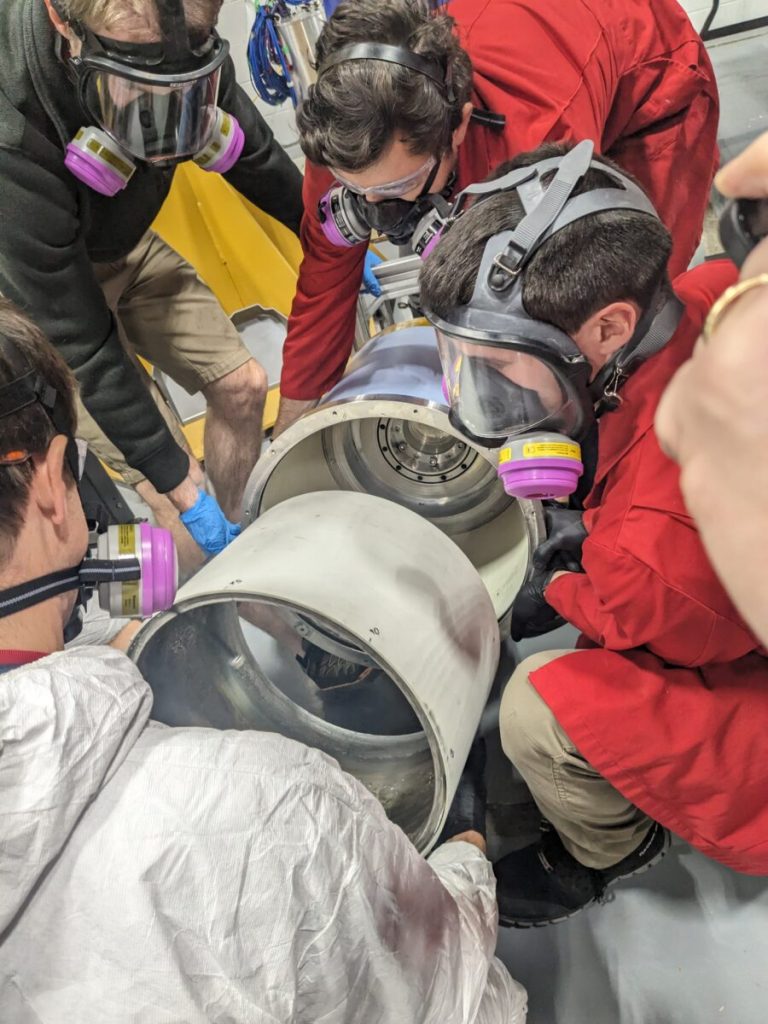

The solid lithium liners compressed in Prototype 0 are the first of their kind. To create the liners, General Fusion designed a custom centrifugal spin casting apparatus. In this method, lithium is melted in a furnace, piped into the horizontal rotating casting machine, and cooled while spinning, freezing the lithium so it becomes a solid liner.

Before each compression shot for Prototype 0, the team meticulously creates a solid lithium liner, which takes about six hours from start to finish.

Global collaborations readied to prove machine performance

A suite of state-of-the-art diagnostics will measure and verify when LM26 reaches fusion conditions. Measuring plasma density, temperature, and energy confinement requires several specialized devices that can understand the performance of a compression shot in incredible conditions – and they can’t do this alone.

They’re tapping into top talent from around the world to validate the results from LM26 and learn from experts who have worked on major fusion projects such as ITER and JET. Canada’s TRIUMF will develop key neutron diagnostics. Reflectometer experts at the University of Lisbon are building a specialized device to measure plasma density. They’ve also teamed up with the UK Atomic Energy Authority to advance polychromators for Thomson scattering to measure electron temperature.

Powering up: Major equipment delivered for scale-up

Procurement for LM26 is underway, with the first major shipment of capacitor banks for the machine’s compression system recently arriving at their labs. Capacitors are like batteries that can hold energy and then pulse it out quickly (like a lightning strike) to create their plasmas. In LM26, the capacitors will provide the high electrical current in the theta pinch coils to compress the plasma with the energy required to reach 10 keV.

Up next on the surest and fastest path to commercial fusion energy

More than 20 years of scientific and engineering progress, combined with a culture of working nimbly and iteratively, has set a tangible path forward for General Fusion to reach historic firsts with LM26. In 2024, they are preparing to assemble LM26’s full-scale compression system, which will be attached to the front end of their operational plasma injector. While the compression system is being assembled, their plasma physics team will complete upgrades to the injector to prepare for the formation of plasmas in LM26. On track to begin compressing plasmas to 10 keV by 2025, LM26 will progress toward scientific breakeven equivalent by 2026.

Fusion energy is poised to revolutionize the energy landscape and pave the way for a sustainable future. Learn more about General Fusion’s world-changing clean energy solution and follow their progress at generalfusion.com and on social media.

Related Story

CNL Announces New Programs to Position Canada to Seize Opportunities in Fusion Energy

Canadian Nuclear Laboratories (CNL), Canada’s premier nuclear science and technology organization, is pleased to announce that it welcomed Canadian and international leaders in fusion science and technology to the nation’s capital for Fusion Day 2024, a forum to discuss and explore the path to fusion deployment in Canada. Hosted by CNL at the Rideau Club in Ottawa, the event served as a venue for CNL to unveil and discuss its ‘Fusion Energy for Canada’ report, a new plan that outlines a collective vision and national strategy to make fusion energy a reality in Canada.