Industrial AI and Sustainability at Scale: Siemens Redefines Industrial Innovation at Hannover Messe

April 19, 2024

- Generative AI for industries: Siemens Industrial Copilot to be available on the Siemens Xcelerator Marketplace this summer

- Siemens and Schaeffler to sign memorandum of understanding to expand work to integrate Siemens Industrial Copilot into all areas of industry

- Live on stage: Siemens and NVIDIA show how they enable the industrial metaverse together

- World premiere of “Electrification X” for a wide range of IoT software-as-a-service offerings for transforming electrification infrastructure

- German Chancellor Olaf Scholz to be among high-ranking visitors at Hannover Messe’s largest booth

The industrial sector is in need of digital transformation toward greater sustainability and resilience. Value creation and actions for the planet must be brought into balance. Companies need to do more with fewer resources. At Hannover Messe, Siemens will show how proven, cutting-edge technology and strong partnerships enable industries to become both more sustainable and more competitive. Visitors at Booth D53 in Hall 9 will experience showcases featuring core technologies for digital and sustainable transformation in the automotive, food, chemicals and semiconductors industries.

“Together with our partners, we will be showcasing how innovations like AI, digital twins and software defined automation can help customers to address multiple challenges. From increasing competitiveness, reducing costs, overcoming labor shortages or increasing sustainability, Siemens has the technologies that industries need right now,” said Roland Busch, President and CEO of Siemens AG.

Siemens press conference and live stage program

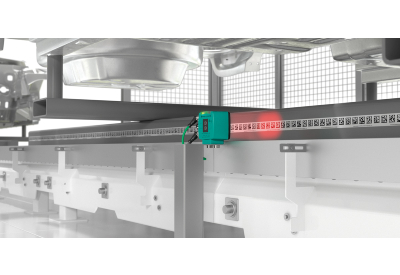

At Hannover Messe, Siemens will be demonstrating how customers can benefit from the Siemens Xcelerator digital business platform. The focus will be on applications such as AI-enabled machine vision and Siemens Industrial Copilot with Microsoft and Schaeffler. The Siemens Xcelerator ecosystem is constantly evolving: the number of partners and sellers nearly doubled in the last year alone.

At a press conference on Monday, April 22, 2024, from 5:30 p.m. to 6:30 p.m. CEST, Siemens will present the latest trends and developments. Journalists can also join the press conference via livestream by registering at: https://siemenspkhannover24.events.dc.siemens.com/

Further activities at the tradeshow will be accompanied by a live stage program featuring members of the Siemens AG Managing Board along with experts, partners and customers.

Roland Busch, President and CEO of Siemens AG, and Rev Lebaredian, Vice President of Omniverse and Simulation Technology at NVIDIA, will discuss the AI-powered industrial metaverse. They will explore the potential of immersive experiences for customers in all industries and showcase how Siemens’ physics-based digital twins powered by NVIDIA Omniverse and AI are driving productivity.

The session “Supercharging transformation: how AI-powered digital twins enable the industrial metaverse” will take place at the Siemens booth on Monday, April 22, at 12 noon CEST. Participating journalists will be able to ask questions afterwards. The talk and Q&A will also be livestreamed: https://www.linkedin.com/events/siemens-nvidia-howai-digitaltwi7182007244371165186/theater/

Chancellor Scholz to experience new era of human-machine interaction with Siemens Industrial Copilot

German Chancellor Olaf Scholz plans to visit the tradeshow’s biggest booth to experience the transformative power of generative AI firsthand. Klaus Rosenfeld, CEO of the Schaeffler Group, will also be present during the Chancellor’s visit because Siemens and Schaeffler are now working together even more closely on digital transformation and generative AI. To this end, both companies will sign a memorandum of understanding to expand their joint work on Siemens Industrial Copilot.

In a world premiere at the SPS tradeshow last fall, Siemens and Schaeffler unveiled an integrated generative AI-powered assistant in a production machine: Siemens Industrial Copilot helps automation engineers speed up the generation of code for programmable logic controllers (PLCs). PLCs are the devices that control most machines throughout the world’s factories. Engineering teams can significantly reduce time, effort and the probability of errors by generating code through natural language inputs.

“Our AI solutions, such as the Siemens Industrial Copilot, show our commitment to combining the real and the digital worlds,” said Cedrik Neike, member of the Managing Board of Siemens AG and CEO of Siemens Digital Industries. “Last year, we presented our vision of putting AI at your fingertips and highlighted the huge opportunities these capabilities will bring. Now, we’re turning this vision into reality by taking AI from concept to scale. And this new reality goes beyond engineering and operations. It’s a game-changing transformation that is also tackling challenges like labor shortage and climate change.”

Decarbonizing industrial operations and buildings

As part of the Siemens Xcelerator portfolio, Siemens is presenting Electrification X for the first time. Built on highly scalable cloud services, Electrification X is designed to manage, optimize and automate the challenged electrification infrastructure of commercial, industrial and utility customers. The aim is to improve efficiency and performance while reducing costs and CO2 emissions.

“The digitalization of buildings, electrification infrastructure and power grids is key for creating a smarter, more efficient and decarbonized industrial sector,” said Matthias Rebellius, member of the Managing Board of Siemens AG and CEO of Smart Infrastructure. “At the industrial tradeshow in Hannover, we’re showcasing our latest products driving sustainable transformation, such as the highly innovative Sentron electronic circuit protection device and SF6-free switchgear. We’re also announcing new partners in our ecosystem. Beyond that, we’re proudly introducing Electrification X, which is a highly scalable, internet-of-things software-as-a-service offering to transform electrification infrastructure.”

Furthermore, Siemens is presenting new apps as part of the Building X digital building platform. They include the Sustainability Manager app, which can be used to achieve greater transparency in the operation of manufacturing and office spaces. In addition, the Comfort AI app enables optimized energy consumption through AI-based control of the entire heating, ventilation and air conditioning system within a building.

Siemens is also adding products for infrastructure and industrial applications to its Siemens EcoTech portfolio. Siemens EcoTech gives customers a comprehensive insight into product performance across selected environmental criteria and is setting a new standard for transparency in the industrial sector. The label represents the next milestone in the company’s long-standing commitment to minimizing the environmental footprint of its own operations and products and to supporting the digital and sustainability transformation of its customers.

More Information

Please find here further information about the Siemens booth:

Hannover Messe 2024 – Siemens Global HM24

Related Story

Siemens and NVIDIA Expand Collaboration on Generative AI for Immersive Real-Time Visualization

Siemens announced that it will deepen its collaboration with NVIDIA to help build the industrial metaverse. Siemens is bringing immersive visualization powered by new NVIDIA Omniverse Cloud APIs to the Siemens Xcelerator platform, driving increased use of AI-driven digital twin technology. At the NVIDIA GTC, the two companies demonstrated how generative AI can revolutionize the visualization of complex data, making photorealism possible, and showcased how sustainable shipbuilder HD Hyundai can use it to develop new products.