How to Build Better Robotics with Integrated Actuators

January 29, 2025

Integrated actuators are transforming the way robotics are designed, offering compact, highly efficient solutions that improve performance and reduce complexity. This detailed article by Harmonic Drive delves into the benefits of integrated actuators, explaining how they combine a motor, gearhead, and feedback system into a single unit to enhance precision, reliability, and space savings.

The piece explores key design considerations, such as selecting the right actuator for the application, optimizing for torque and speed, and addressing thermal management. It also highlights how integrated actuators streamline the development process by eliminating the need for separate component sourcing and assembly, making them ideal for robotic applications across industries like manufacturing, healthcare, and autonomous systems.

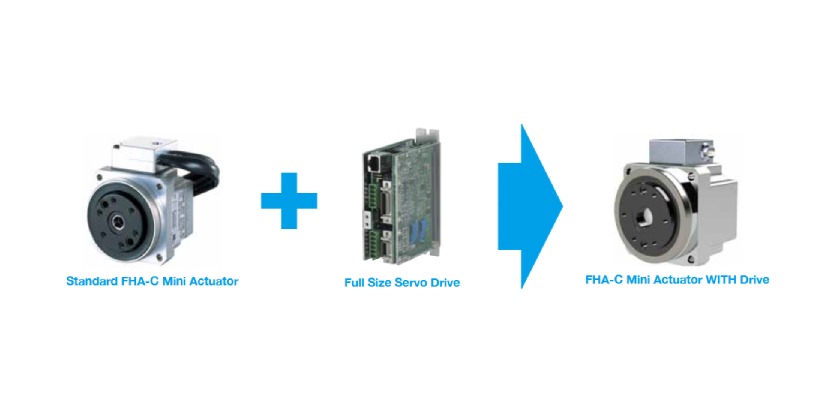

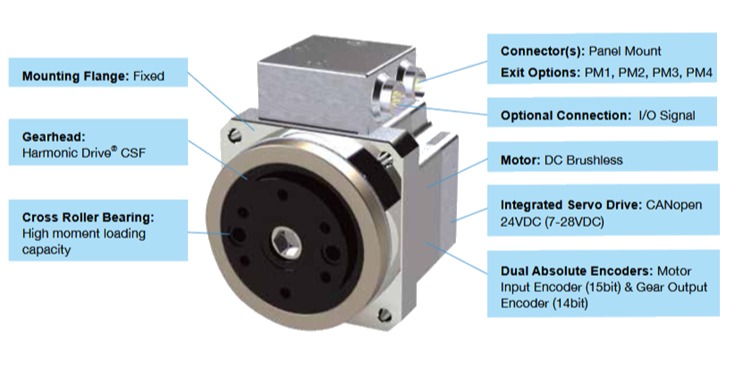

The FHA-C and SHA series actuators from Harmonic Drive® exemplify advanced integrated actuator technology. The FHA-C series features a compact, flat design with a hollow shaft, combining a dedicated flat AC servo motor with Harmonic Drive® precision gearing. This configuration offers high torque and positional accuracy, making it suitable for applications where space is limited.

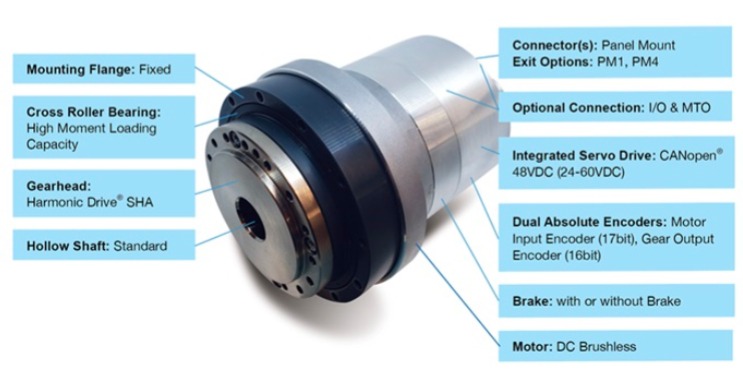

Similarly, the SHA series actuators integrate a brushless servomotor, precision strain wave gearing, dual absolute encoders, and an integrated servo drive with CANopen® communication. This design eliminates the need for an external servo drive, simplifying cabling while delivering high positional accuracy and torsional stiffness in a compact housing.

More Information

For engineers and designers looking to advance their robotic systems, this guide provides valuable insights into the technology’s potential to improve motion control, boost efficiency, and simplify development.

To learn more read the full White Paper from Harmonic Drive

Related Story

New Harmonic Drive HPF Series: High-Performance Hollow Shaft Gear Unit

The new Harmonic Drive® HPF Series has quickly become a go-to choice for engineers requiring high-torque solutions in compact spaces. Its precision gearing, reliability, and versatility make it ideal for robotics, automation, and other high-performance applications that require exact motion control.