HMS Networks Launches the Anybus Wireless Bolt II to Help Industrial Companies Increase Uptime

April 27, 2023

HMS Networks now releases the Anybus® Wireless Bolt™ II, an industrial Wi-Fi 5 access point (AP) and wireless distribution system (WDS) client. While remaining as user-friendly as its predecessors, the Wireless Bolt II features even better durability, security, and performance. With faster speeds and increased throughput, it is an excellent complement to the existing range of Wireless Bolts and an ideal choice for applications that demand high data transfer rates.

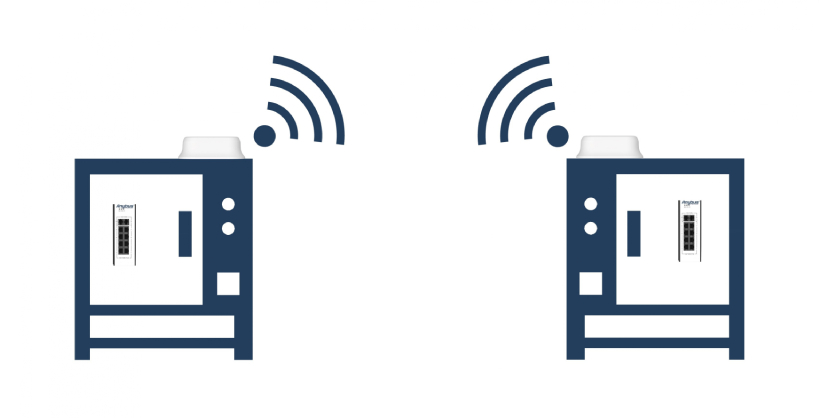

The Anybus Wireless Bolt II is an excellent fit for companies seeking to avoid the high costs and inconveniences of traditional installations with cables. It can be configured as an Access Point to provide wireless access, where it enables data accessibility and increases operator safety. Alternatively, by using a pair of Wireless Bolt IIs, a wireless bridge can be achieved for industrial Ethernet networks such as PROFINET, Modbus TCP, and EtherNet/IP, replacing cables in both point-to-point and point-to-multipoint applications. Additionally, the rugged design makes the Wireless Bolt II ideal for industries operating in harsh environments, such as manufacturing, where uptime is critical.

Improved Wireless Technology

With the use of Wi-Fi 5 and MIMO antennas, the Anybus Wireless Bolt II offers very fast and reliable wireless performance, leading to improved connectivity and reduced data loss.

Advanced Security

The Anybus Wireless Bolt II supports HTTPS and WPA3 security protocols, providing a more secure wireless network and protecting against unauthorized access and data breaches.

Durability and Robustness

Built to withstand the harshest industrial environments, the Anybus Wireless Bolt II features a robust enclosure that is impact-resistant (prepared for IK10 and ATEX) and ingress-protected (certified for IP66 and prepared for IP69K). The Wireless Bolt II can operate in a wide temperature range of -25°C to 65°C, making it suitable for indoor as well as outdoor use.

Easy Installation and Integration

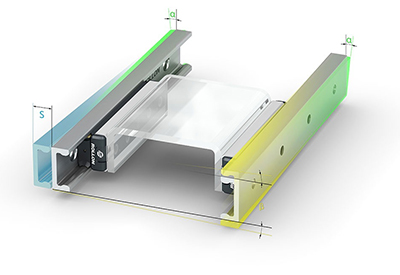

Setting up and configuring the Anybus Wireless Bolt II is easy, thanks to its intuitive user interface. With its time-tested through-hole mounting method, the Bolt II can be securely mounted onto cabinets and equipment without exposing any wires, making it look like an integrated part of the installation. The Bolt II can be easily integrated into existing systems, saving time and effort compared to installing new cabling and/or infrastructure.

Samuel Holst, Product Manager at HMS Networks, comments, “We’re thrilled to introduce the Anybus Wireless Bolt II to the industrial connectivity market as we are confident that it will help our customers to solve the recurring problem of broken or damaged cables bringing production to a halt. The Bolt II is robust and easy to install, but most importantly, it allows companies to avoid the costs and inconveniences of traditional cables and increase system uptime.”Samuel Holst, Product Manager at HMS Networks

Use Case examples

More Information

Related Product

HMS Network’s Anybus Products: Connecting Robot Accessories to Any Industrial Network

Robots need accessories to work efficiently. But what’s the easiest way to connect the accessories to factory

networks? The easiest way is to use HMS Networks’ ready-made Anybus products, as RSP found out.

The number of industrial robots operating in factories worldwide continues to rise. To use robots efficiently

and maximize productivity, companies attach robot accessories to the robots to enable the robots to perform

different tasks.