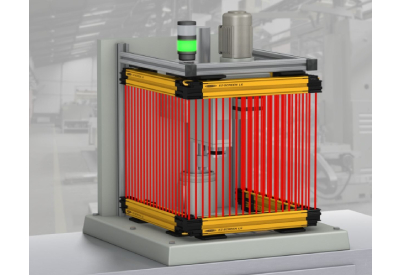

Heavy-Duty Type 4 Safety Light Curtains from Banner

February 17, 2022

EZ-SCREEN® LS light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand challenges commonly found in manufacturing and packaging environments. They are easy-to-use an have several resolution options available to detect fingers, hands, arms, or legs. They are built to withstand harsh industrial environments.

Features and Benefits

- •Highly visible alignment indicators and intuitive diagnostics simplify setup, facilitate troubleshooting and minimize system downtime

- •Three resolutions (detection capability) available: 14, 23, and 40 mm with a range of up to 12 m (39 ft)

- •Each emitter and receiver features a 5 mm recessed window and is protected against impact by a 3 mm thick aluminum housing and metal end caps

- •System requires no PC software, DIP switches, or other device for quick, easy configuration

- •Dual scan technology makes the sensor highly immune to EMI, RFI, ambient light, weld flash, and strobe light

- •No blind zone design provides end-to-end sensing to eliminate gaps in detection

- •Cascade up to four systems of any length, resolution and number of beams

- •IP65/IP67 rated emitter/receiver pairs exceed OSHA/ANSI control reliability requirements and are certified to Type 4 per IEC 61946, Category 4 PLe per EN ISO13849.1, and SIL3/SILCL3 per IEC 61508/IEC 62061

Application Examples

- •Small assembly station protection with light

- •Safeguarding access points to a depalletizer

- •Dual-operator robotic workstation

- •Safeguarding of a power press

- •Guarding personnel at meat slicing machine

For the LS Series Safety Light Screen brochure, click here

To learn more about Banner’s Light Curtains, click here