HANNOVER MESSE: Ready For Anything With the MOVI PLC I/O System C

April 21, 2021

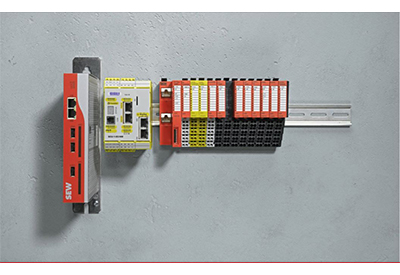

In conjunction with the new MOVI C CONTROLLER portfolio, interaction between the product portfolio of SEW EURODRIVE and external field units is optimized. An end-to-end solution, the I/O system combines a high level of performance and the latest functions with a well thought-out mechanical concept.

EtherCAT and CANopen interface modules are available for data exchange with the controller when using this solution. The I/O modules are equipped with a power supply module and support up to 64 electronics modules on the backplane bus.

The I/O system is perfectly integrated into the SEW EURODRIVE automation portfolio. It offers both analog and digital I/Os plus input and output modules with functional safety, a bus coupler, function modules, and modules for power supply, distribution and accessories.

Thanks to its high-performance bus, the MOVI PLC I/O system C boasts a transmission rate of 48 Mbit/s and response times as short as 20 μs. The secure sliding mechanism makes it easy to install. Click connection ensures quick mounting of the shield connection on the module, while a step-shaped wiring level with spring clamp technology makes for a very space-saving design. Last but not least, upright wiring ensures easy replacement of modules.