Gems ULS-200: Optimizing Liquid-Level Sensing for Power Generation

February 20, 2025

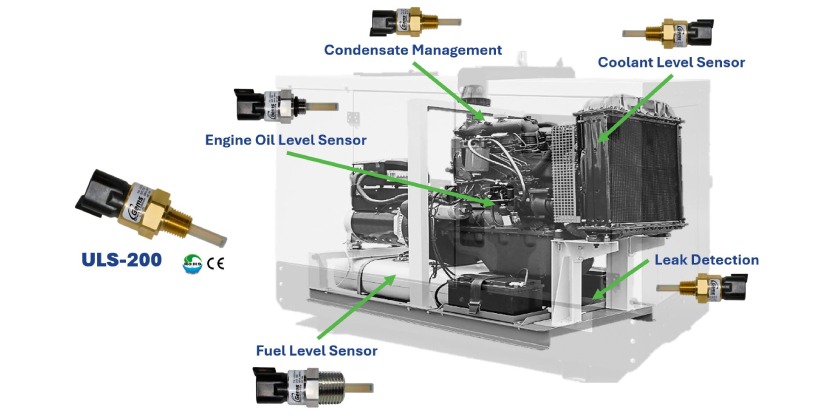

Gems ULS-200 Solid-State Point-Level Sensor

The power generation industry relies on precise and reliable sensors to ensure seamless operation, safety, and efficiency. Within generator sets (gensets) and power generation systems, accurate liquid-level monitoring is critical for everything from cooling systems to fuel storage. The Gems ULS-200 solid-state point-level sensor is engineered to meet these demanding requirements with cutting-edge technology and robust construction.

How the ULS-200 Works

The ULS-200 sensor uses advanced capacitive sensing technology to detect liquid levels by measuring changes in the dielectric constant of the medium. This solid-state design eliminates moving parts, ensuring durability and reliability even in harsh environments. Its configurable features, such as time delays and wet/dry signal options, make it adaptable to various applications in power generation.

Applications in Power Generation

The ULS-200 is a versatile solution for multiple liquid-level sensing needs in power generation equipment:

- Fuel Tank Monitoring

Reliable fuel level monitoring is critical to maintaining consistent operation of gensets. The ULS-200 provides accurate point-level detection in fuel tanks, ensuring operators are alerted when fuel levels are low to prevent unexpected shutdowns. - Coolant Level Detection

Overheating can lead to significant damage and costly repairs. The ULS-200 monitors coolant levels with precision, helping to maintain optimal engine temperatures and reduce downtime. - Oil Reservoir Monitoring

Proper lubrication is essential for the longevity of generator engines. The ULS-200 ensures oil levels are adequately maintained, preventing excessive wear and tear on moving parts. - Wastewater and Condensate Management

Gensets often produce wastewater or condensate that needs to be managed effectively. The ULS-200 can detect high levels in these reservoirs, ensuring timely removal to avoid overflows and maintain system hygiene. - Leak Detection

Unaddressed leaks in fuel, coolant, or oil systems can lead to environmental hazards, operational inefficiencies, and costly repairs. The ULS-200 excels in detecting leaks, providing an early warning system to prevent further damage and ensure compliance with environmental regulations.

Features and Benefits for Power Generation

- Rugged Construction: Built with robust materials and sealed to IP6K9K standards, the ULS-200 withstands exposure to water, dust, and pressure, making it ideal for demanding environments.

- Wide Temperature Range: Operates reliably from -40°F to 257°F (-40°C to 125°C), ensuring performance under extreme conditions.

- High Vibration Resistance: Tested to IEC 60068-2-64 standards, it endures vibrations up to 2000 Hz, making it ideal for equipment with significant mechanical movement.

- Optional Time Delays: Configurable delays prevent false readings caused by liquid turbulence or sloshing.

- Flexible Outputs: Compatible with various control systems, including sinking and sourcing output configurations.

Why Choose the ULS-200 for Power Generation?

With its advanced design and reliability, the ULS-200 simplifies operations, reduces maintenance costs, and improves system performance. Its versatility and durability make it the ideal choice for addressing the diverse liquid-level sensing needs of power generators and gensets.

Explore the Gems ULS-200 and learn how it can enhance power generation applications.

Related Story

Optimizing Liquid Cooling in Data Centers: Gems Sensors’ Role in Coolant Distribution Units (CDU)

As data centers continue to evolve to meet the demands of high-density computing workloads, liquid cooling has emerged as a game-changing technology. Offering improved thermal efficiency, reduced energy consumption, and the ability to handle increasing heat loads, liquid cooling systems are becoming indispensable for next-generation data centers. At the heart of many liquid cooling implementations is the Coolant Distribution Unit (CDU), a critical component that ensures efficient coolant management. Gems Sensors provides innovative solutions to optimize CDU performance, offering reliable sensing technologies for level, pressure, flow, and valve control.