MiR Robot Fleet from Forvia Increased Logistics Productivity in Czechia

March 10, 2023

Investment in 14 MiR robots provided the Tier 1 automotive supplier with production stability and reliability in its Czech plant with return on investment (ROI) in less than 2 years

FORVIA has increased its logistics productivity, strengthened stability of production processes and decreased safety risks with a fleet of robots robots from Mobile Industrial Robots (MiR). The return of investment (ROI) from the 14 autonomous mobile robots (AMR) working in the Faurecia Clean Mobility plant in Písek (Czechia) was less than two years.

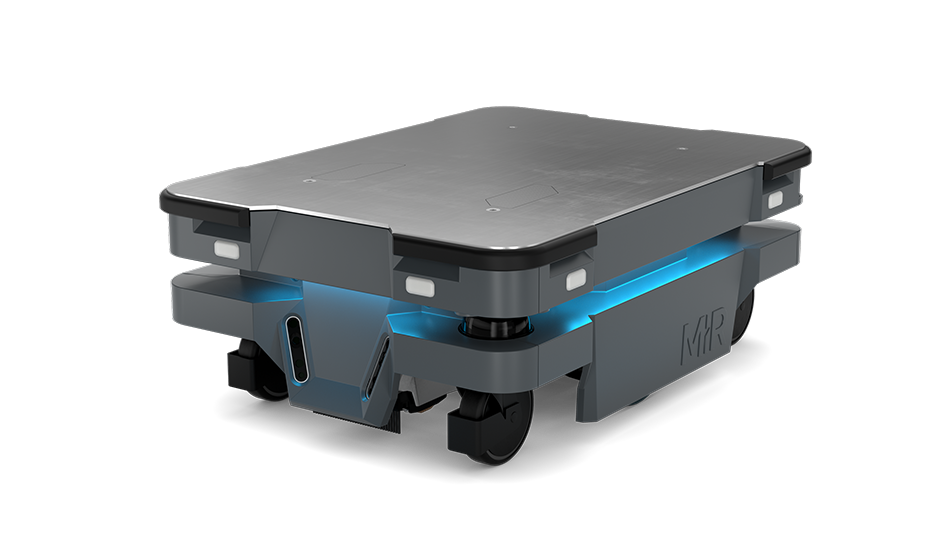

Seven of FORVIA’s heavy duty MiR robots, mainly MiR600s, work in the area of finished goods, bringing empty pallets to the assembly lines and picking up full pallets to transport to the logistics area. The second area, where MiR250 robots operate, moves components from the warehouse to assembly lines. The robots in the plant work 24 hours a day, 7 days a week, covering all three operation shifts.

Before FORVIA initiated the project, the logistics on the shop floor relied mostly on manual processes, forklifts and stackers equipment, without any automation. In fact, the company considered the risk of human injuries has been quite high, and FORVIA decided to automate the heaviest and most dangerous processes. The principal goal was to bring technology that increases the safety and productivity.

MiR Fleet is used to organize missions. Together with using internal script, the software helps to optimize the logistics flow to the lines and between the lines. All the communication with doors, gates, a strapping machine etc. is fully automatic without the need for operator assistance. A target for the next year is to integrate MiR Fleet into the company’s ERP system.

MiR robots provide customer with full autonomy, enabling them to easily set up new routes without additional magnetic tapes or other external guidance necessary for using other intralogistic technologies. The MiR robots and people work well together and avoid bottlenecks, as the intelligent robots can recognize people on the shop floor and can stop or bypass them without decreasing the robots’ efficiency.

General benefits of deploying MiR robots span into three main areas:

- Improved safety by eliminating forklifts on the shop floor

- Increased productivity in all areas of operations

- Return on investment. In Faurecia Písek, the payback was less than 2 years.

“Mobile robots help us bring more discipline to the shop floor and make our production processes more stable and reliable, especially important is stability for operating all three shifts,” Martin Horáček added. “What we appreciate most about these robots is their autonomy, meaning they move freely on the shop floor without any specifically needed equipment,”

For more details see the full video and written case study here.

Related Video

Logistics Industry | Fully Autonomous RFID-based Inventory System Uses OMRON Mobile Robots

How did Omron’s autonomous mobile robots (AMRs) help smart inventory solutions provider T&W Operations eliminate manual and forklift-dependent processes in their fully autonomous RFID inventory system?