Festo’s Aluminum Pneumatic Tubing for Welding Cells Outperforms Steel, Laminated Alternatives

May 17, 2022

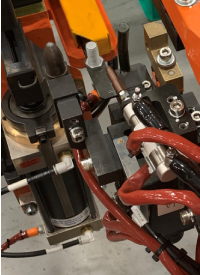

Festo’s innovative PM aluminum pneumatic tubing offers a weld-spatter resistant solution in welding cells that outperforms laminated and steel pneumatic tubing on durability, flexibility, ease of installation and installed cost. PM tubing is ideal for new welding cells and as a cost-and-time efficient retrofit solution.

PM aluminum tubing can be located closer to the welding process than laminated tubing, creating a more efficient pneumatic setup without the worry of burn through. There are no clearance issues with PM tubing as it has a nominal outside diameter versus some laminated options.

PM tubing is designed for use with standard pneumatic push connectors right out of the box, while laminated tubing typically requires specialized tools and/or oversized connecters where technicians must strip away the lamination in order to use standard connectors. Once formed, Festo’s PM aluminum tubing holds its shape and stays in place without the need for additional clips and tie downs.

This Festo aluminum solution also is significantly less costly than steel tubing. Steel requires specialized tools to bend the tubing, but PM tubing is easily formed by hand to conform to the contours of the welding system.

Ontario’s Sodecia an early adopter of PM tubing

London, ON-based Sodecia GTAX is a global Tier 1 supplier of structural components to the automotive industry with a core competency in designing, building and providing training for its MIG welding production cells. Sodecia is constantly researching product solutions that provide improved efficiencies.

“Festo’s PM aluminum tubing is an example of this constant improvement,” says Robert Remillard, Sodecia GTAC Engineering Manager. “We’ve found Festo’s PM tubing to be the best possible solution for our cells, maintaining all the benefits of conventional tubing with the added advantages of flame resistance at a significant cost and time reduction.”

Remillard lists the improvements that PM pneumatic tubing have delivered compared with past solutions Sodecia has used.

Remillard lists the improvements that PM pneumatic tubing have delivered compared with past solutions Sodecia has used.

- •It’s Inherently resistant to high temperatures

- •It’s less bulky

- •It requires no specialized tooling and connectors

- •It is profiled by hand

- •It can be inserted or removed from connectors multiple times without degradation of a tight, leak-free seal

- •It retains its shape for quick reinstallation

- •There is no need for multiple anchor points.

For more information on PM tubing, contact Festo at marketingmarketing.canada@festo.comanada@festo.com and visit www.festo.ca for information on the full range of the company’s automation products.