Festo Introduces the World’s First Proportional Valve Terminal

December 3, 2024

Manufacturers gain design and energy benefits plus productivity quality from this moderate air-flow solution.

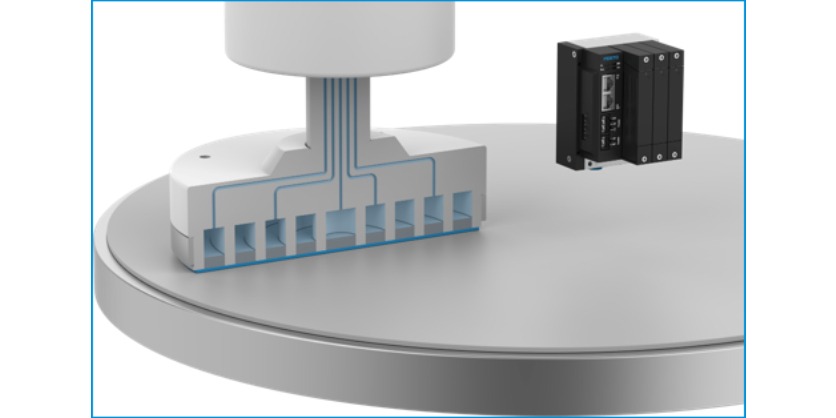

Festo introduces the VTEP, the world’s first proportional valve terminal. The VTEP is an ideal solution for flexible gripping, web tensioning, force-controlled polishing, precision piloting, dispensing, dosing, and diaphragm pump control.

The VTEP valve terminal provides closed-loop control of moderate air flow – vacuum up to 35 l/min. It comes in 2-, 3-, and 5-valve variants, which can control up to 10 channels. It is less than 5 inches wide, a benefit for today’s smaller footprint machines. VTEP features an EtherCAT digital communication interface for real-time communication and full data transparency.

Each valve contains an integrated pressure-temperature sensor, an airflow control algorithm, and four digitally controlled 2/2 piezoelectric cartridges. The cartridges are arranged in a bridge circuit, allowing two independent channels to be controlled by a single valve.

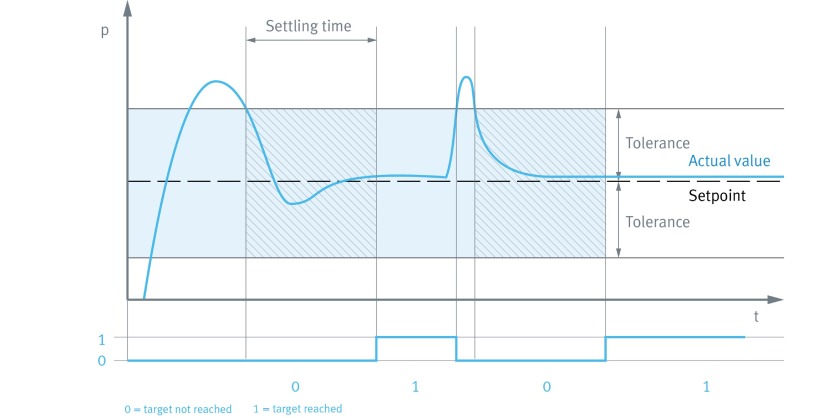

Users set performance parameters per channel and the valves provide closed-loop controls to those presets. Valves deliver highly dynamic response and precise pressure control to achieve “target reached” status for each channel, similar to the “motion complete” function in electric drive technology. Based on feedback from the valve’s temperature and pressure sensor, the embedded control algorithm automatically maintains the target position.

This VTEP valve terminal is the latest addition to Festo’s line of Controlled Pneumatics solutions – pneumatic products that control complex applications, while at the same time reduce the number of components, simplifying implementation and conserving energy. Festo Controlled Pneumatics products include the VTEM motion terminal for high flow rate applications, VEAB proportional pressure control valve for pressure ranges up to 6 bar, and the VPPI proportional pressure regulator.

More Information

For more information on the VTEP proportional valve terminal, contact a Festo sales representative or a Festo distributor. For more information on the advantages of working within the Festo ecosystem of less engineering overhead, fast time to market, seamless connectivity, and high quality components, visit www.festo.com.