Festo Develops a New Flexible Pipetting Solution

This new solution is capable of pipette dispenses from 20 microliters up to 20 milliliters.

February 1, 2024

Festo is now showing customers and prospects several new life science automation innovations including the company’s wide-range flexible pipetting. Each of the new and customizable solutions combines Festo components into dynamic subsystems. Festo collaborates with OEMs and integrators to bring proven commercial technologies to labs around the globe.

“LifeTech is the fastest growing segment within Festo,” said Sam Stoney, LifeTech Industry Segment Manager. “We believe the reason for exceptional growth is that our product portfolio in high-speed sample and media handling is second to none, as is our Boston-based application engineering team. Festo supports its products globally and reduces risk through its robust and reliable supply chain.”

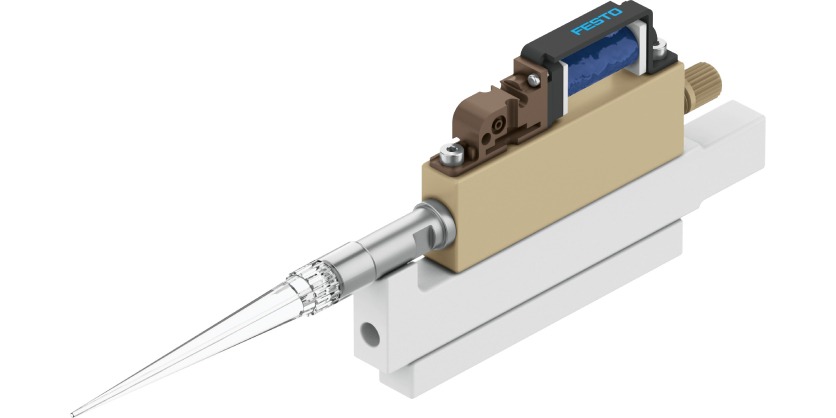

The new wide-range pipetting system scales seamlessly from 20 µl up to 20 ml for bulk transfer. Users change pipetting volumes via a text-based HMI; in practice the system can be controlled by any automated system using standard Ethernet protocols. Featured components include the Festo DHOE open loop pipette head and the ultra-compact PGVA pipetting and dispensing controller.

The DHOE pipette head can transport extremely small volumes down to 1 µl with outstanding precision. Thanks to its chemical resistance, the DHOE accommodates a wide range of liquids of varying viscosities. The solution shows how a single versatile system can serve many functions – a plus for laboratory and screening device manufacturers that look to deliver greater flexibility to their customers.

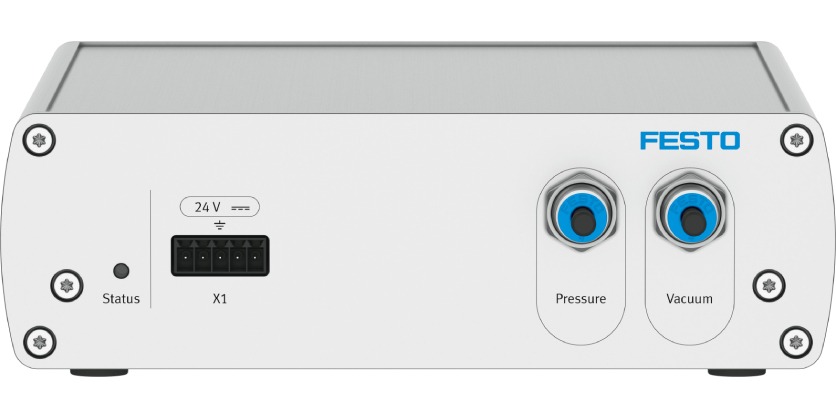

The PGVA pipetting and dispensing controller is a compact solution for environments without a central compressed air supply. A single PGVA can supply air pressure to multiple pipette or dispensing heads. The PGVA allows the pressure supply (positive or vacuum) to be centralized within the machine. It operates silently with precision thanks to its industry leading piezoelectric-based valves.

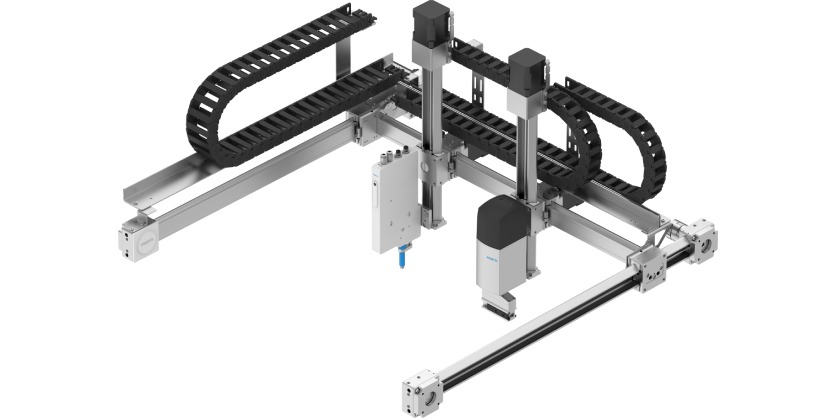

In a second development, Festo is now showing a gantry robot featuring three axes of motion (X, Y, and Z) and eight independently controlled Z-axes. Multiple Z-axis increases the flexibility of the sample and media handling systems by fitting more workflow into less space. Customers can opt for the number of Z-axes optimum for their machine.

Featured components include the latest iteration of the Festo EXCL life-science optimized gantry robot, which customers receive as a kit that is easily assembled in hours. EXCL kits come complete with all key components, from power connector to energy chain, motors, and motion control. Festo assigns gantries unique part numbers for simplified reordering. The company developed an online configuration tool that makes specification fast and optimized to the needs of the application. Other featured Festo components include the CMXL motion controller, PGVA pipetting and dispensing controller, DHOE pipettor, and DHAP pipette tips.

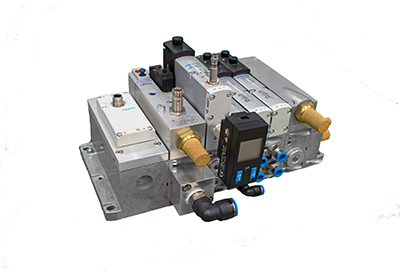

Festo’s liquid dosing system can aspirate liquid droplets from two bulk wells and dispense them into microwell plates. The system adjusts flexibly. Following filling, the liquids are aspirated away in a bulk transfer, and the pipette tip can be automatically replaced. Key Festo life-science components include the EXCM-30 bench-top gantry robot, ELGC linear actuator, CMXL motion controller, PGVA pipetting and dispensing controller, DHOP smart pipettor, DHAP pipette tips, VAEM valve controller, and VTOI dispense/aspirate head.

Festo also has a liquid dispensing system for small volumes of liquid. Liquids are dispensed with the VYKA media separated valve. Using hit-and-hold current reduction circuits in a VAEM valve controller, valve opening time is quickly and precisely controlled, which reduces heat transfer to the media. Other featured Festo components include the VTOF dispensing head for the VYKA valve, VYKB media separated valve, VAVN dispense needles, and PGVA pipetting and dispensing controller.

More Information

For more information on Festo Life-Science solutions – dispensing liquids, controlling gases, and handling samples ‒ email life.sciences.nam@festo.com and visit Festo Laboratory Automation. Visit www.festo.us for the full range of products.

Related Product

Festo’s New DHOP Advances Lab Automation with High-Throughput Pipetting with Closed-Loop Control

Festo’s new DHOP closed-loop pipette head for high-speed robotic pipetting applications delivers consistent volumes over a wide range of liquid viscosities. In so doing, it assures the utmost in automation flexibility, speed, and feedback where devices are frequently required to handle many liquids.