Festo Expands Portfolio of Solutions for Automating EV Battery Manufacturing

October 4, 2024

Festo has created a new solution for high throughput dry-room electrode assembly of electric vehicle (EV) batteries. It’s the latest in a series of innovations Festo has developed for the entire battery lifecycle. In 2022, the Festo electric mobility initiative demonstrated an automated degassing cell. In 2023, the company developed an automated chemical processing solution for recycling the valuable materials incorporated within EV batteries.

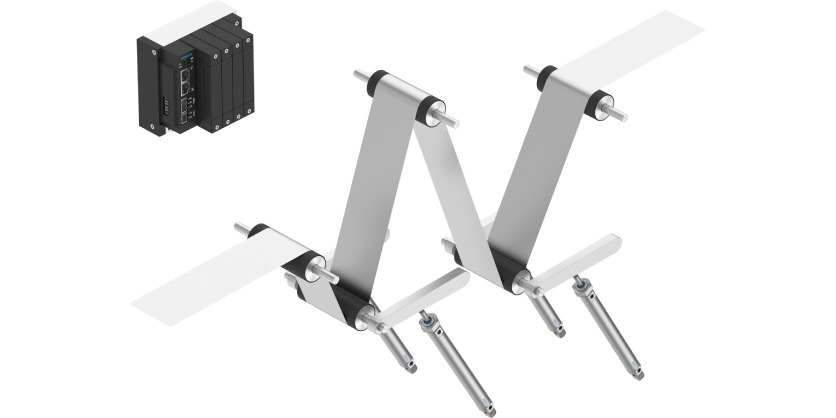

This year’s focus on dry-room electrode production covers unrolling, cutting, aligning and layering of anodes and cathodes. The first high-precision proportional valve terminal on the market, according to the company – the new Festo VTEP – is used to maintain roll tension, which is critical to the quality of EV batteries. It does so at a significant cost saving compared to electric automation.

VTEP is the latest Controlled Pneumatics solution from Festo. Controlled Pneumatics is the next stage in the evolution of pneumatic solutions for the 21st century. Controlled Pneumatics solutions combine high-speed, long-life, and energy-efficient piezo-electric valve cartridges with sensors and control algorithms into a single smart unit.

With VTEP, users set performance parameters per valve channel and the proportional pressure valves provide closed-loop control to those presets. Valves deliver highly dynamic response and precise pressure control to achieve “target reached” status for each channel, which equates to the motion complete function in electric drive technology. Sustaining the target setting makes the VTEP terminal ideal for maintaining roll tension in automated dry room electrode production.

This automated chemical processing solution for EV batteries also highlights the performance advantages linked to huge bandwidth – 200-megabyte rate – and exceedingly low cycle time – under 100 milliseconds – of the new Festo Automation Platform (AP) I/O. The AP’s CPX-AP-A remote I/O and CPX-AP-I decentralized I/O communicate at backplane speed. This I/O architecture is compatible with EtherNET/IP, PROFINET, EtherCAT, Modbus, and IO-Link by applying a protocol-specific AP bus module. This is a plus for OEMs supplying multiple control systems on serial machines as the bus module changes, while the I/O stays the same.

The Festo components for dry room applications are copper and zinc free, which adhere to best industry practice. The company offers copper and zinc free options in dozens of product families, including valve manifolds, actuators, air preparation systems, and accessories. Festo copper and zinc free product variants feature a “F1A” designation in their model numbers.

Closing the skills gap – the disparity between skills needed by industry and the number of workers with those skills – is vital to the health of EV and semiconductor manufacturing due to the number of new plants and revitalization projects coming online. Festo Didactic, the learning arm of the company, now offers Electromobility Training online through the Festo Learning Experience portal, on-site customized training, and expertise in establishing and maintaining apprenticeship programs.

More Information

For more information on Festo innovations in electric mobility, visit the Festo website and look under the Solutions Tab for the Automotive Industry.

Festo at a glance

Festo, one of the world’s leading suppliers of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Founded in 1925, the family-owned company based in Esslingen, Germany supports a wide range of needs for advanced solutions in factory and process automation. The company has been supporting Canadian industry for almost 50 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support.

Globally, some 300,000 customers put their trust in the company’s pneumatic and electric drive products and technology. In addition, Festo Didactic provides state-of-the-art training equipment and educational programs for industrial companies and educational institutions – about 56,000 customers worldwide. The Festo Group registered sales of €3.65 billion in the 2023 financial year and is represented worldwide at 250 locations with about 20,600 employees. About 7.7% of its annual turnover is invested in research and development.

Related Story

Battery Formation for EV Batteries: A Critical Step in Battery Production

Festo is a leading supplier of pneumatic and electrical automation technology, and they are supporting the Canadian automotive industry with innovative products, optimized motion control solutions, and unrivaled support. In this article, two of their subject matter experts, Jarod Garbe, Industry Segment Manager – Automotive, and Lawrence Lin, Emerging Technologies Business Development Manager -EV Batteries, shed more light on the subject. They discuss their products and solutions for EV battery production – with a particular focus on battery formation – arguably, the most critical part of the process.