Emerson’s Solenoid Valves Enable More Compact Machine Designs

March 3, 2021

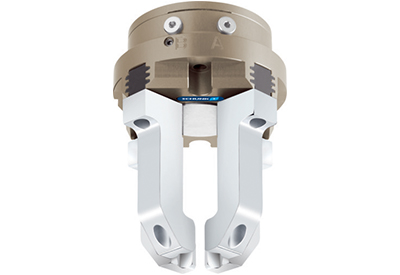

Emerson has launched a range of two-way and three-way solenoid valves that support original equipment manufacturers’ (OEMs) need to develop more compact machines and equipment without compromising on fluid control performance. The optimized body design and internal flow path of the new ASCO™ Series 256/356 not only provides a smaller footprint, but also reduced power consumption and increased pressure ratings critical in industrial and commercial applications.

The reduced overall footprint of the Series 256/356 helps OEMs optimize the internal layout of their equipment, enabling more high-performance fluid control options to be integrated into a smaller and sleeker final product. This is especially important for manufacturers of coffee machines and other beverage dispensers; heating, ventilation and air conditioning; pumps and compressors; welding equipment; and analytical and medical devices.

Achieving comparative pressure ratings in a smaller valve typically results in increased power consumption, but the Series 256/356 reduces energy use by as much as 40%. This enables OEMs to apply a smaller valve while matching or improving on the fluid control performance of the previous version and make significant energy savings.

The pressure rating of some versions of the redesigned Series 256/356 has increased by up to 30% compared to the previous versions, enabling them to be used in more demanding applications, such as high-pressure washers and hydrogen fuel dispensers. The performance of the DC voltage version is now similar to that of the AC voltage version, enabling overall system costs to be reduced by eliminating the need to convert to AC power to maximize solenoid valve performance.

“Emerson has engineered the Series 256/356 from the ground up, creating a range of solenoid valves that sets a new benchmark in fluid control technology by decreasing overall footprint and power consumption while also increasing pressure ratings,” said Erik VanLaningham, vice president of global marketing for Emerson’s industrial automation business. “These performance improvements are complemented by an extended choice of body materials and connection options. This provides OEMs with the broadest range of options from a trusted single-source supplier to reliably meet their diverse application demands.”

The Series 256/356 offers an expanded selection of body materials, including lead-free brass, stainless-steel and an engineered composite material that is 20% lighter than brass and meets global health and safety standards for food and beverage applications. The valves are dust-tight, IP67-rated and submersible in up to one meter of water, making them suitable for harsh environments, increasing reliability and extending the life of machinery. Third-party approvals for a wide variety of industry standards, such as NSF 169 and EC 1934 for food and beverage applications, helps OEMs reduce the time-to-market for new products.

The Series 256/356 has multiple end-connector options and flexible electrical connections, reducing installation time by up to 40% and making service and maintenance much easier.