Electromate Extends Its Product Portfolio to Include Collaborative Robots Manufactured By Universal Robots

May 19, 2021

Electromate Inc., a Canadian Distributor of Precision Robotic & Mechatronic Solutions, has recently announced a partnership with Universal Robots A/S, a Denmark based premier manufacturer of high-performance Collaborative Robotics.

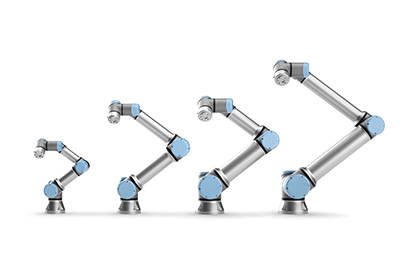

Electromate is expanding its robotics and automation product family with Universal Robot’s versatile line of collaborative robots. Manufacturers around the world are turning to automation to help solve labor shortages, increase productivity, and improve product quality. Universal Robots’ collaborative robots provide a cost-effective, flexible, and safe automation solution for a wide range of production tasks.

Universal Robot is dedicated to bringing safe, flexible, and easy-to-use 6-axis industrial robotic arms to businesses of every size, all over the world. They develop industrial collaborative robots that automate and streamline repetitive industrial processes. This approach enables production departments to assign staff members to more enjoyable tasks – creating jobs that provide them with new challenges and add value to their company.

“In the world of collaborative robots, Universal Robots provides the most flexible, user-friendly and cost-effective solution on the market,” explains Warren Osak, CEO and founder of Electromate. “It’s no surprise that Universal Robots has already sold more than 50,000 collaborative robots which are used in several thousand production environments every day around the world. Combining Universal Robot’s revolutionary collaborative robot product line with Electromate’s world-class customer service, Canadian manufacturers now have a new option to automate many of their machine tending applications”.

For more information, visit www.electromate.com.