Customers Build Their Collaborative Robot Applications With UR Guidance

April 21, 2021

Universal Robots (UR) is on the cutting edge when it comes to industrial automation with its collaborative robot arms, or “cobots”, available in Canada through Advanced Motion & Controls Ltd. Not only does UR manufacture innovative products; it also gives customers everything they need to start building their collaborative robot applications.

UR offers convenient step-by-step guidance online that offers insight into the various options available, simulations of running applications, and downloadable packages with design, program, and interface tips.

From machine tending to packaging and beyond

The UR team makes devices that work for various collaborative robot applications. Among the most common of these are machine tending, screwdriving, and packaging, and many other applications are possible with these UR cobots.

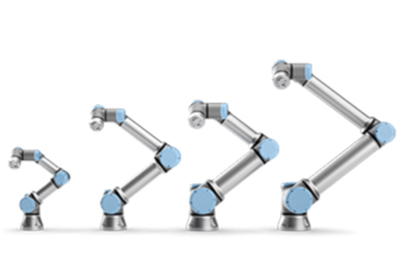

For machine tending, Advanced Motion & Controls offers several UR cobot options that are all collaborative, easy to program, and incredibly precise. Customers should decide on the proper unit based on reach and payload requirements. Choices include the UR3e, the UR5e, the UR10e, and the UR16e. The UR3e is a small, collaborative tabletop robot recommended for light assembly applications and automated workbench tasks. The UR5e is lightweight, easily programmable, and highly customizable for many scenarios, and UR’s largest cobot, the UR16e, is built for bigger tasks that require precision and reliability.

The manufacturer also offers options for polishing, buffing, and even sanding, as these tasks require a specific, often delicate touch. A Universal Robot with force control offers a flexible solution that will automatically adjust position to achieve the desired force. This valuable capability comes standard with the Universal Robots e-Series line of cobots without the additional cost and complexity of other manufacturers.

For packaging applications, UR offers units that are easy to program and extremely precise, and customers should select one based on reach and payload needs. The UR3e, UR5e, UR10e, and UR16e are all ideal for packaging tasks, depending on the specifics.

These are just three examples of collaborative robot applications with which UR can help businesses to optimize. Customers can allow the Advanced Motion & Controls Sales Group to make specific recommendations for other scenarios.