Creative Motion Control: Variable Speed Linear Actuator

June 3, 2021

A Short Introduction To Linear Actuators

An electromechanical linear actuator serves as a standard machine component that converts an electric rotary motor’s rotational movement into a linear force. Linear actuators require a power source input and a control signal input to function. When receiving energy and a control signal input, a linear actuator will create linear force to perform a specified mechanical task.

What Are Variable Speed Linear Actuators?

Variable speed linear actuators utilize the same electromechanical principles as a standard linear actuator to generate a push and/or pull movement. However, with a variable speed linear actuator, users can control the amount of force created to dictate the speed at which the actuator operates.

A linear actuator consists of the following main components:

- ● AC or DC motor

- ● Gearbox

- ● Spindle or lead screw

- ● Rod

- ● Drive nut

The push/pull force generated by a linear actuator allows machines to lift, lower, or otherwiseadjust a target based on an operator’s external signals. Electric actuators remain safe to use and easy to install. Typically, machines utilize actuators to perform repetitive tasks that mayprove too hazardous to execute manually.

As the number of applications for linear actuators continues to grow, the consumer publicbecomes more exposed to their purpose and function. We now see linear actuators in homes,used for various convenient tasks like lifting a pop-up television or standing desk.

Variable speed linear actuators provide operators with an increased level of control over a given subject matter, improving a specified task’s overall safety and producing more reliable, accurate results.

Electric linear actuators cost less, last longer, and require less clearance than most hydraulic and pneumatic actuators. Plus, they represent an environmentally friendly, energy-efficient solution to many everyday tasks.

Types of Variable Speed Linear Actuators

Designs for variable speed linear actuators continue to evolve and improve. They have become more precise, accurate, and efficient over time, leading to the development of high-speed actuators. Let’s go over the main types of variable speed linear actuators.

Rod

Rod actuators represent the most commonly known type of actuator. This type of actuator comes in two main forms: classic and bullet. Let’s discuss both styles of rod actuators in turn.

Classic

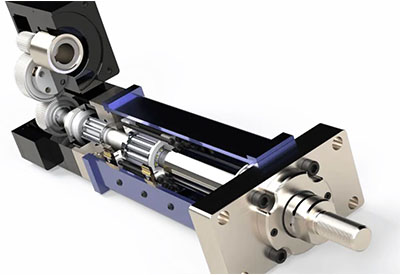

Classic or standard rod actuators serve as the most widely seen style of linear actuators. They consist of:

- ● AC or DC motor – The motor converts electricity into rotational motion.

- ● Gears – The gears slow the rotational force, increase torque, and transfer energy to the lead screw.

- ● Lead screw – The lead screw rotates, forcing the rod into inward and outward linear motion.

- ● Rod – The rod’s movement allows the actuator to push, pull, and adjust an object.

With classic rod actuators, the motor remains mounted to the side of the rod. In most cases, it sits parallel to the rest of the actuator. In other cases, such as some ultra high-speed linear actuators, it rests perpendicular to the rest of the device.

Bullet

Inventors developed the bullet rod actuator to fit into tight spaces. Instead of a side-mounted motor, bullet actuators possess an in-line motor, creating a slimmer, sleeker profile. The thinner profile allows for new applications that previously seemed too intricate for the extra bulk of a side-mounted motor. As a result, bullet actuators have a more extended design than classic ones.

Track

Much like rod actuators, track actuators possess an AC or DC motor, gears, and lead screw. However, in place of a rod, track actuators have a carriage that slides along the length of the rotating lead screw. The length of a track actuator’s stroke remains limited to the length of the lead screw or spindle. The limits on range-of-motion make track actuators simpler to integrate. One major drawback of track actuators involves the tracks themselves because they sit outside the device. This design exposes the tracks to grease, grime, dust, and other debris, which can gum up the works and impede the carriage from sliding up and down the tracks.

Lifting Columns

Lifting columns also possess a motor, gears, and lead screw but have neither a rod nor carriage. Instead, the lead screw pushes out one of several collapsing, telescopic columns. As their name implies, lifting columns lift objects along a vertical axis. This movement restricts the number of applications available to lifting columns, but it also allows manufacturers to make them more rugged than the other types of linear actuators.

The Benefits of Variable Speed Linear Actuators

A linear actuator with variable speed offers potentially limitless benefits due to the frequent discovery of new applications. However, certain benefits will apply to the use of all variable speed actuators. Let’s go over some of the most common benefits of variable speed linear actuators.

Simple Design

Compared to that of pneumatic and hydraulic options, the simpler design of an electric linear actuator allows for a greater range of applications. An electric linear actuator easily incorporates into existing machinery, requires fewer replacement parts, and demonstrates a high level of reliability.

Easy Installation

In most cases, electric linear actuators represent the easiest mechanical solution. Integration with other machine components proves trouble-free because the electrical energy input and electrical signal input allow a linear actuator to interface well with computer processors and other electrical equipment.

Durability

The simple design of a linear actuator increases the device’s overall durability. A well-made linear actuator will last for years, if not decades, without much maintenance. This longevity makes linear actuators an ideal mechanical solution when incorporated into products used by unsophisticated consumers.

Low Maintenance

The ever-growing popularity of electric linear actuators stems from their reliability, even without receiving regular maintenance. Owners of a linear actuator need only apply lubrication on rare occasions. Other than that, keeping the device free from damage represents the only care users

need to provide.

Low Operating Cost

Compared to hydraulic and pneumatic linear actuators, electric actuators cost very little tooperate. Whereas hydraulic and pneumatic actuators require constant power to maintain position, an electric actuator can hold its place without any energy consumed. Plus, electric actuators remain less likely to break down than hydraulic and pneumatic options.

Compact Size

Electric actuators take up far less space than pneumatic and hydraulic linear actuators. This benefit expands the number of applications for electric linear actuators because their smaller size allows for creative new ways to integrate them into complex machinery. Also, the compact profile of electric actuators leads to a smaller footprint of the machine into which it is integrated.

Quiet

Individuals who have ever used a hydraulic and pneumatic linear actuator know how much noise they can produce. Upon reaching full extension or retraction, non-electrical actuators can create a loud banging sound. On the other hand, electric actuators create far less noise, making them suitable for more sensitive applications.

Environmentally Friendly

Electric actuators rely on relatively clean energy. A rare failure of an electric linear actuator produces no toxins or contaminants. However, the failure of a pneumatic or hydraulic actuator can lead to the expulsion of various forms of pollution into the local environment. For this reason, electric actuators serve as the preferred solution for sensitive projects.

Common Uses for Variable Speed Linear Actuators

It would prove impossible to count all of the current uses for variable speed linear actuators because new applications emerge every day. Human creativity has lent itself to developing thousands of systems with integrated linear actuators, from practical, useful projects to wacky, over-the-top art installations.

Take a look at some of the more common, practical uses for variable speed linear actuators:

- ● Agricultural equipment

- ● Food and beverage manufacturing

- ● Robotics

- ● Automatic sliding doors

- ● Sliding windows

- ● Adjustable solar panels

- ● Particulate collection containers

- ● Automatic sliding side steps in vehicles

- ● Mechanized hatches

- ● Automatic cutting devices b ● Kitchen appliance lifts

- ● Automatic valves

- ● Electronic throttle control

- ● Computer printers

Who Manufactures Variable Speed Linear Actuators

Variable speed linear actuators play a crucial role in countless machines. The versatility and cost-effectiveness of actuators generate high demand. To meet this demand, many companies manufacture variable speed linear actuators. Some manufacturers focus on making actuators for particular purposes. But, many companies create multipurpose actuators for general use.

Many of the companies that produce high-quality actuators operate out of the United States. For example, Creative Motion Control manufactures innovative linear actuators that possess unique grooved roller bearing and planetary roller screw designs. These designs contribute to longer lifespans for their actuators and increase their load capacity.

Businesses and consumers will find a wide variety of variable speed linear actuators on the market. For that reason, it remains vital to select the correct actuator for a particular project. Choosing a suitable, high-performance actuator provides increased efficiency and extended longevity while picking the wrong actuator will create current and future headaches.