The New CB10 I/O Hubs with IO-Link from Pepperl+Fuchs: Maximum Flexibility in the Smallest Space

April 11, 2023

Push button boxes are used in numerous industrial applications. Connecting these to an IO-Link master not only entails higher costs but also additional cabling efforts. It is significantly more economical to connect several push buttons to one port. It has therefore been difficult so far to use IO-Link as an interface in push button boxes. With their particularly compact design, the new CB10 series I/O hubs offer the optimal solution for direct integration into the smallest installation spaces. The CB10 modules can be connected directly to the master and make push button boxes I/O-Link-capable this way.

Versatile and Robust Modules

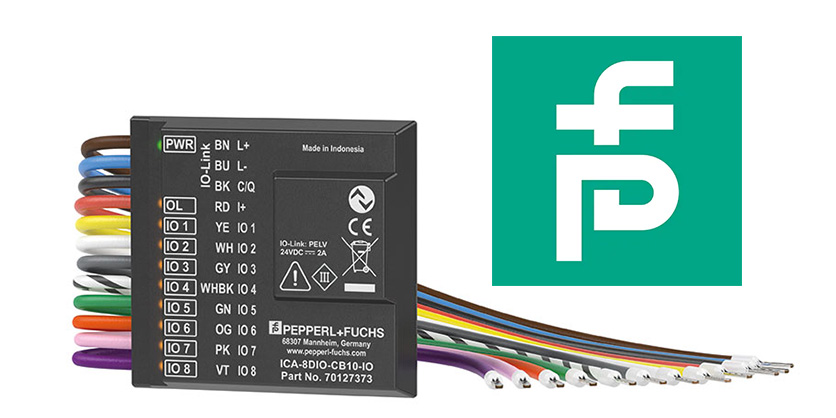

The space-saving I/O hubs enable the connection of up to eight standard devices in IO-Link networks. Freely configurable digital inputs/outputs ensure the greatest possible application diversity, reaching from use in stack lights to the connection of mechanical contacts such as in push button boxes, to the connection of 3-wire sensors. Due to the compact housing design of 39.5 x 36 x 10.1 mm, the modules can be integrated even into the smallest panels and customer-specific electronics.

Therefore, the innovative hotmelt technology not only enables the realization of the particularly space-saving housing design, but also the production of robust and shock-resistant housings for the highest quality and durability of the CB10 I/O hubs.

Fast and Easy Installation and Commissioning

In addition to their flexibility, the I/O hubs are characterized by a high level of user-friendliness during assembly and commissioning. The modular solution enables easy integration into IO-Link networks and allows OEMs to preassemble push button panels in the plant. This way, the modules are directly connected to the application.

The different wire colors and pre-crimped leads ensure accurate and fast installation of the modules. Moreover, LED outputs integrated into the housing indicate any errors that may occur.

Highlights of the CB10 I/O Hubs with IO-Link

- Compact I/O hubs enable the connection of up to eight standard devices to IO-Link networks

- Freely configurable digital inputs/outputs for maximum flexibility

- Universally applicable: variants for mechanical push buttons, 3-wire sensors, and signal lamps

- Different wire colors and pre-crimped leads for accurate and fast installation

- Space-saving, robust, and shock-resistant housing due to innovative manufacturing in hotmelt technology

Related Product

The New Simple—Double Sheet Sensors with IO-Link Interface from Pepperl+Fuch

Reliable double material detection is easier than ever before with the new range of IO-Link double sheet sensors in an M18 or M30 design from Pepperl+Fuchs, the market leader in ultrasonic sensor technology. Whether detecting paper, foil, wood, metal, or even highly reflective solar wafers, UDC-18GS-*IO-* and UDC(M)-30GS-*IO-* sensors stand out from other standard double sheet sensors on the market thanks to their incomparably simple parameterization and maximum flexibility.