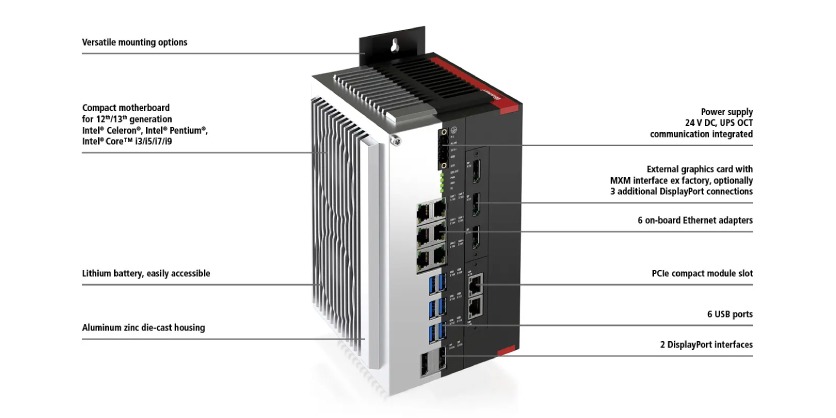

C6043 | Ultra-Compact Industrial PC

July 31, 2024

The C6043 extends the series of ultra-compact industrial PCs to include a high-performance device with a built-in slot for powerful graphics cards. With the latest Intel® Core™ processors and highly parallelizing NVIDIA graphics processors, the PC becomes the perfect central control unit for ultra-sophisticated applications. These include applications with high demands on 3D graphics or deeply integrated Vision and AI program blocks with minimal cycle times. The Beckhoff TwinCAT 3 control software is capable of mapping this as a fully integrated solution – without any additional software or interfaces. With the additional freely assignable PCIe compact module slot, the C6043 can be flexibly expanded with supplementary functions.

The use of Intel® Core™ processors in the 12th and 13th generations gives the C6043 enormous computing power, with the Intel® Core™ i5, i7, and i9 processors built in a hybrid architecture for the very first time. As with previous generations, Intel® Celeron®, Pentium®, and Core™ i3 are equipped exclusively with classic performance cores. Four additional efficiency cores are added to the Core™ i5, eight to the Core™ i7, and sixteen to the Core™ i9 processors. This combination of performance and efficiency cores allows applications to be implemented on a total of up to 24 real cores.

While performance cores are primarily suitable for high-performance, single-thread applications, many additional threads can be executed in real time or in user mode on the additional efficiency cores. Each individual core can be individually configured in clock frequency, just as it can with the 11th generation of Intel® Core™ processors. The power supply and the cooling have sufficient reserves to utilize the available computing power of the processors and the external graphics card.

Depending on the graphics performance, the system is balanced in terms of available CPU power to always get the maximum out of the application. Measuring 132 x 202 x 127 mm (W x H x D), the device remains incredibly compact despite its computing power and represents yet another milestone in terms of power density.

Flexible mounting

In particular the wide variety of mounting options for the rear panel of the control cabinet or the DIN rail should be highlighted with this Industrial PC series. The connection level can be freely oriented, i.e. adapted to possibly specified cable layouts. Due to their maximum flexibility, the PCs fit in any niche in the control cabinet, however small.

Price-optimized

Due to the optimized housing and manufacturing concept, all Industrial PCs from the C60xx series are cost-optimized and are often less expensive in direct comparison with other series in the Industrial PC product area without restrictions in industrial compatibility, quality or durability.

All-in-one motherboard

The basic concept of the series always provides for an all-in-one motherboard developed and self-manufactured by Beckhoff. The single-board PCs are characterized by further improved robustness and durability. Modular, functional extensions in the form of a second board level can be integrated in every motherboard via an internal plug connector.

Advantage at the very core: the Beckhoff Industrial PCs

Beckhoff is a pioneer in PC-based automation technology and has been developing and producing its own PC hardware since 1986. The technology know-how that has grown over the past decades is incorporated today into all Beckhoff Industrial PCs. Their principle feature is the use of state-of-the-art components and processors of the highest performance class. Combined with a high in-house production depth, including proprietary motherboard production, long-term component availability, extremely flexible configuration and customer-specific adaptations, Beckhoff presents itself today as one of the world’s leading Industrial PC manufacturers.

Related Story

Linux®-Based Real-Time Control with TwinCAT from Beckhoff

With the TwinCAT Runtime for Linux®, Beckhoff is opening up new application possibilities for real-time control. In the future, several TwinCAT Runtimes can be executed on a single industrial PC for the first time, enabling users to combine different system parts on one large computer, for example. With this hardware consolidation, computing resources are better utilized. Furthermore, accessing a GPU (graphics card) from the real-time environment will be possible, which is used as a hardware accelerator for particularly computing-intensive applications such as vision.