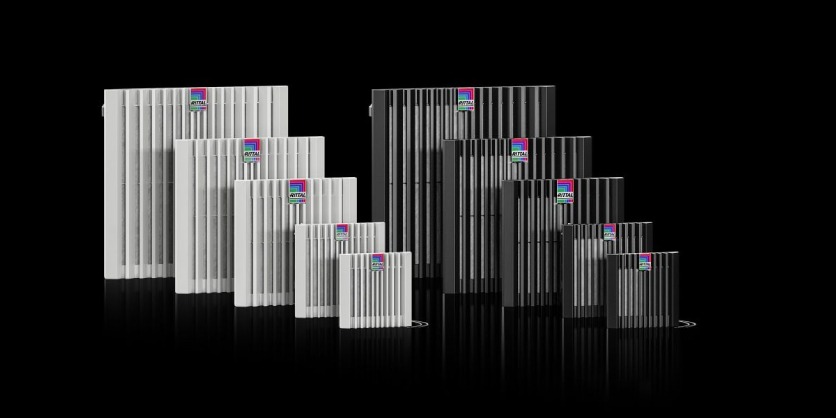

Blue e+ Fan-and-Filter Unit: More Power for Your Enclosure Cooling

June 12, 2024

Rittal Blue e+ fan-and-filter units help you to achieve your climate goals while at the same time reducing your energy costs. The 40% greater air throughput of the new fan-and-filter unit with pleated filter – compared to a chopped-fibre filter – is unrivalled by any other unit on the market.

You benefit from an enclosure cooling solution which combines power, efficiency and simplicity. Our fan-and-filter units are available in AC/DC, EC and EMC options. Use of a fan-and-filter unit with EC technology, in particular, secures significant time and cost advantages, because IoT capabilities boost energy efficiency and system reliability.

Discover how the new Blue e+ fan-and-filter units can contribute to decisive improvements in your daily operations.

Blue e+ fan-and-filter units: Your benefits at a glance

Powerful

- More performance: The 40% greater air throughput of the integrated pleated filter enables cost savings, as you can now choose a unit from a lower output class

- Extended service life for components: The unique diagonal fan technology provides for more even and constant ventilation of the enclosure

Efficient

- 60% energy savings (EC fan-and-filter units) thanks to the efficient motor

- Cost and time savings thanks to the 2-3 times longer replacement interval of the standard pleated filter

- Reduced unit maintenance costs (EC fan-and-filter units) thanks to automatic filter cleaning, which extends service life by 20%

- Lower energy and service costs (EC fan-and-filter units) thanks to optimisation of the service intervals based on demand-oriented filter maintenance and virtual indication of the remaining operating hours

Reliable

- Alarm relay for added peace of mind (EC fan-and-filter units): Malfunctions are reported directly

- IoT capabilities for improved operational security (EC fan-and-filter units): The integrated emergency cooling function responds to temperature rises by increasing air throughput by up to 40%

- Multi-voltage capabilities for unlimited applications (EC fan-and-filter units): Guaranteed suitability for worldwide use

Simple

- Simple planning: Optimised parameterisation and product selection with tools such as RiTherm, RiPanel, Eplan Data Portal and ProPanel

- Simple conversion: Mounting cut-outs, protection ratings and output classes correspond to those of the previous generation of fan-and-filter units

- Simple assembly: Time savings thanks to tool-free mounting (simple snap-fit mounting on the enclosure)

- Simple maintenance: Tool-free handling and simple filter mat replacement

- Simple monitoring (EC fan-and-filter units): Control and monitoring via analogue or digital interfaces

Impressive IoT features of the EC fan-and-filter units

Predictive maintenance

The operating hours and running speeds of the EC motor are logged continuously. In a similar manner to the fuel gauge of a motor vehicle, the Rittal IoT Interface shows when the next filter replacement is due. This helps you to reduce your service costs.

Filter cleaning

Automatic filter cleaning is activated several times over the course of a day: The air flow direction is reversed briefly enabling the filter to be “blown clean”. Fine dust particles caught in the filter are removed. This extends the filter replacement interval by 20% and your service costs are reduced accordingly.

Emergency cooling function

Excessive temperature rises in the enclosure can lead to system failure. The emergency cooling function of the EC fan-and-filter unit responds actively to avert such problems. As soon as the temperature exceeds the defined alarm threshold value, the fan speed is increased to its maximum. This results in up to 40% higher air throughput to prevent or at least delay overheating of the installed components.

Pleated filters: Your benefits at a glance

Lower energy costs

- The six times larger surface area compared to a standard chopped-fibre filter results in a lower pressure drop and enables faster dissipation of the waste heat from the enclosure.

80% greater air throughput with IP 55 protection compared to a chopped-fibre filter

Improved operational reliability

- The material and construction of our pleated filters ensure that even tiny dust particles are retained reliably. Particles measuring just 0.3 micrometres can be filtered from the air. That is smaller than some viruses. In practical terms: Significantly less dust enters the enclosure.

50% greater dust retention

Reduced service costs

- Thanks to their larger surface, pleated filters boast a significantly higher retention capacity. This, in turn, means that maintenance intervals can be extended. Furthermore: Our pleated filters guarantee protection to IP 54 or IP 55 (when the pleated filter is used in conjunction with an absorber mat).

2–3 times longer maintenance intervals

More Information

Related Story

Learn How You Can Improve Your Climate Control Efficiency by Upwards of 90%

Rittal’s solutions expert will work diligently to connect you with the nearest partner who can assist in creating a customized solution tailored to your specific needs. Whether it’s enhancing productivity, minimizing downtime, or optimizing your technology, Rittal is committed to streamlining your journey to efficiency. Trust them to be your reliable partner in success.