Axiom Space, Prada Unveil Spacesuit Design for Moon Return

October 21, 2024

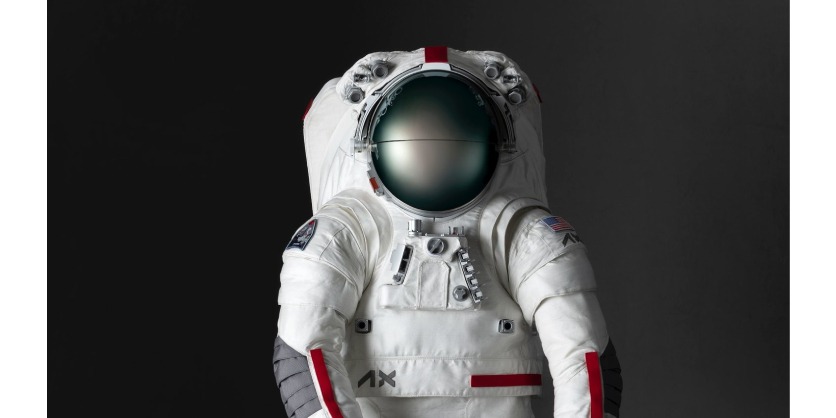

At the International Astronautical Congress in Milan, Italy, Axiom Space and Prada revealed for the first time on October 16, the flight design of the Axiom Extravehicular Mobility Unit (AxEMU) spacesuit that will be used for NASA’s Artemis III mission.

The outer-layer design and materials work was jointly developed starting when the two industry leaders came together, blending creativity and engineering to enhance the next-generation spacesuit design.

“Our elite teams have redefined spacesuit development, establishing new pathways to innovative solutions and applying a state-of-the-art design approach for the AxEMU,” said Matt Ondler, Axiom Space President. “We have broken the mold. The Axiom Space-Prada partnership has set a new foundational model for cross-industry collaboration, further expanding what’s possible in commercial space.”

During development, Axiom Space used a dark cover layer for display purposes only to conceal the suit’s proprietary technology. However, the spacesuit worn on the lunar surface will be made from a white material that reflects heat and protects astronauts from extreme high temperatures and lunar dust.

Lorenzo Bertelli, Prada Group Chief Marketing Officer and Head of Corporate Social Responsibility said, “Going beyond our limits is one of the company’s values that perfectly reflects the spirit of the Prada brand and my parents’ vision. I’m very proud of the result we’re showing today, which is just the first step in a long-term collaboration with Axiom Space. We’ve shared our expertise on high-performance materials, features, and sewing techniques, and we learned a lot. I’m sure we’ll continue to explore new challenges, broaden our horizons, and build new scenarios together.”

Prada’s in-depth knowledge and experience on materials and production processes supported innovative work in addition to the spacesuit cover layer. Prada’s design and product development team worked alongside Axiom Space engineers on customized material recommendations and features that would both protect astronauts against the unique challenges of the lunar environment and visually inspire future space exploration.

Prada’s expertise enabled advanced technologies and innovative sewing methods to bridge the gap between highly engineered functionality and an aesthetically appealing white outer layer, providing astronauts with an increased level of comfort while improving the materials’ performance.

The AxEMU program epitomizes how the commercial space industry is enabling non-traditional partnerships to enhance space exploration capabilities. Since being awarded its first Artemis task order in 2022, valued at $228 million, Axiom Space has capitalized on the public-private agreement with NASA, seeking out renowned experts in diverse industries to aid in developing and designing this next-generation spacesuit.

“We are pioneering a new era in space exploration where partnerships are imperative to the commercialization of space,” said Russell Ralston, Executive Vice President of Extravehicular Activity, Axiom Space. “Partnerships build a strong, cohesive team, enabling industry experts to provide cutting-edge technology, specialized products and services to drive innovation. For the first time, we are leveraging expertise in other industries to craft a better solution for space.”

AxEMU DevelopmentAdvancing NASA’s Exploration Extravehicular Mobility Unit (xEMU) spacesuit design, the AxEMU provides increased flexibility, performance, and safety, as well as specialized tools to aid in exploring the lunar south pole. The suit accommodates a wide range of crewmembers, including males and females from the first to 99th percentile (anthropomorphic sizing). It will withstand extreme temperatures at the lunar south pole and endure the coldest temperatures in the permanently shadowed regions for at least two hours. Astronauts will be able to perform spacewalks for at least eight hours.

The AxEMU incorporates multiple redundant systems and an onboard diagnostic system to ensure safety for crewmembers. The suit also uses a regenerable carbon dioxide scrubbing system and a robust cooling technology to remove heat from the system. It includes advanced coatings on the helmet and visor to enhance the astronauts’ view of their surroundings, as well as custom gloves made in-house featuring several advancements over the gloves used today. The spacesuit architecture includes life support systems, pressure garments, avionics and other innovative systems to meet exploration needs and expand scientific opportunities.

Axiom Space developed the AxEMU using a single, foundational architecture. The architecture is evolvable, scalable and adaptable for missions on the lunar surface and in low-Earth orbit (LEO).

Axiom Space has iteratively improved this next-gen spacesuit over the past two years to support the Artemis III mission. The AxEMU has undergone extensive testing and simulations with a wide range of astronauts and engineers at state-of-the-art Axiom Space, SpaceX and NASA facilities. Testing was conducted underwater to simulate the lunar environment with an unoccupied spacesuit at NASA’s Neutral Buoyancy Laboratory (NBL) and reduced gravity simulations at NASA’s Johnson Space Center.

The AxEMU suit is nearing the final development stage. It completed a successful pressurized simulation with Artemis III partners – NASA, SpaceX, and Axiom Space – marking the first test of its kind since the Apollo era. It will continue to undergo testing including crewed underwater tests at the NBL facility, integrated tests with the Artemis Lunar Terrain Vehicle prototypes, and will enter the critical design review phase in 2025.

For more information, visit www.axiomspace.com/axiom-suit.

ABOUT AXIOM SPACE

Axiom Space is guided by the vision of a thriving home in space that benefits every human, everywhere. The leading provider of human spaceflight services and developer of human-rated space infrastructure, Axiom Space operates end-to-end missions to the International Space Station today while developing its successor, Axiom Station – the world’s first commercial space station in low-Earth orbit, which will sustain human growth off the planet and bring untold benefits back home. For more information about Axiom Space, visit www.axiomspace.com.

ABOUT PRADA

Since 1913, Prada has been synonymous with cutting-edge style. Its intellectual universe combines concept, structure and image through codes that go beyond trends. Its fashion transcends products, translating conceptuality into a universe that has become a benchmark to those who dare to challenge conventions focusing on experimentation. The Prada brand is part of Prada Group, a global leader in the luxury goods industry, which owns some of the world’s most prestigious luxury brands including Miu Miu, Church’s, Car Shoe, the historic Pasticceria Marchesi and Luna Rossa.

Related Story

MDA Announces Second Commercial Sale of Space Robotics Technology to Axiom Space

MDA Ltd., a leading provider of advanced technology and services to the rapidly expanding global space industry, recently announced the second commercial sale of its products derived from Canadarm3 technology to Axiom Space. The new contract is for the delivery of 62 payload interface pairs for Axiom Space’s Axiom Station. The interfaces will provide mechanical, electrical, and data connections for payloads that are externally mounted on Axiom Station to perform activities including scientific research, Earth observation, communications, and a host of other applications.