The MX7 ULTRA – ANCA Launches Its Premium, Next Generation Machine Range to Produce the Highest Accuracy and Quality Cutting Tools in the World

October 12, 2022

Introducing one nanometre axis resolution, the new MX7 ULTRA machine’s performance can maintain less than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius endmills

The new MX7 ULTRA can manufacture large volumes of endmills and other cutting tools of the highest accuracy and quality. The minute size of a micron is beyond the human eye, but in becoming even more precise and moving from micrometers to nanometers, ANCA will offer the highest accuracy and quality in a cutting tool in the market. New software, hardware and design features are combined to make significant advances in surface finish, accuracy, and controlled runout, to deliver batch consistency from the first ground tool to the thousandth.

The new MX7 ULTRA can manufacture large volumes of endmills and other cutting tools of the highest accuracy and quality. The minute size of a micron is beyond the human eye, but in becoming even more precise and moving from micrometres to nanometres, ANCA will offer the highest accuracy and quality in a cutting tool in the market. New software, hardware and design features are combined to make significant advances in surface finish, accuracy, and controlled runout, to deliver batch consistency from the first ground tool to the thousandth.

The MX7 ULTRA includes:

- nanometre control system,

- new servo control algorithm for smooth motion,

- system and mechanical upgrades enhance stiffness and rigidity,

- in-process measuring, balancing and runout compensation for consistent accuracy,

- Motor Temperature Control (MTC) – compensation for thermal expansion on the grinding spindle, and

- specialist training support in how to grind industry leading cutting tools.

Pat Boland, ANCA co-founder says: ““The MX7 ULTRA is a significant development in precision machine design and I am confident it will bring major benefits to our customers. I am very proud of the ANCA team that have developed the MX ULTRA. Engineering have delivered significant developments across all aspects of machine tool design and applications which the market will see in the superior grinding performance of our latest products.”

Pat Boland, ANCA co-founder

“The ULTRA machine is truly market-changing. It is the culmination of ANCA’s elite technology, deep industry knowledge, and customer experience in grinding,” says Thomson Mathew, ANCA product manager for the MX series and software products.

Unlike its competitors, ANCA is vertically integrated. This provides a significant advantage as it means ANCA teams can develop and manufactures their own machines from base to canopy – including controls and drive systems, design and simulation software and even machine monitoring software. Owning all the technology means engineers and designers can consider the entire machine as a single system when developing new solutions.

“We wanted to create technology that could produce premium cutting tools that are above the current market standard in both accuracy and tool life. We introduced nanometre resolution into our axis, which is new to the cutting tool market. The result is a perfect example of ANCA’s vertical integration capabilities as we have the in-house ability to fine tune or develop the new algorithms for our drives to make this happen.”

“Cutting tools like ballnose, corner radius, barrel shape ballnose and double corner radius endmills are used widely across industries including diemold, aerospace, and power generation. The surface finish quality, accuracy and runout are critical for the performance and cutting life in all applications – so our customers want a guarantee that their first tool will be exactly the same as the hundredth, or thousandth. The MX7 ULTRA can produce high quality cutting tools to suit all customer needs to satisfy all industry types.”

“With almost 50 years of expertise, ANCA are experts in the field of cutting tools and we want to impart our knowledge through best grinding practices. As part of the ULTRA experience, skilled application engineers will be available to train and educate our customers to ensure the machine will produce high quality tools from the first day of production.”

“It has taken years of research and development, and engineering excellence for us to develop this premium solution to grind high quality tools. In my 25 years in the industry, I believe this is one of the most outstanding innovations we have accomplished that will really change the cutting tool market. We are confident that our customers will be very satisfied with the life and performance of cutting tools produced on this premium machine,” Thomson concluded.

The MX7 ULTRA superior performance highlights

Greater control for the velocity and acceleration or deceleration along with machine jerk limits:

To increase the stiffness of the C-axis, the MX7 ULTRA combines developments to the nanometre or micro degree resolution in the linear and rotary axis, tuning parameters, several system enhancements, and major mechanical changes.

ULTRA-fast response to internal or external disturbances:

ANCA’s newly designed servo control algorithm allows silky smooth motion of an axis with the use of a unique algorithm and nanometre measurement in the control system. This will create finer cutting edges and eliminating micro-chips making it more efficient while used in actual machining of materials.

Better cycle time and higher productivity of high-quality cutting tools:

The unique algorithm is key to the performance of the machine and ensures outstanding tracking performance. It also allows ULTRA-performance of the servo system without using a complex, complicated, or expensive mechanical system.

Reduces setup times and scrap:

Cutting-edge software has been developed by ANCA to ensure batch consistency in large volumes. LaserUltra is part of the MX7 ULTRA package to maintain consistency and accuracy of the grinding process which includes in-process measurement and compensation to accommodate wheel wear and other external variations during large batch grinding. Its analog capability can maintain less than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius tools.

Increased wheel life and better-quality tools:

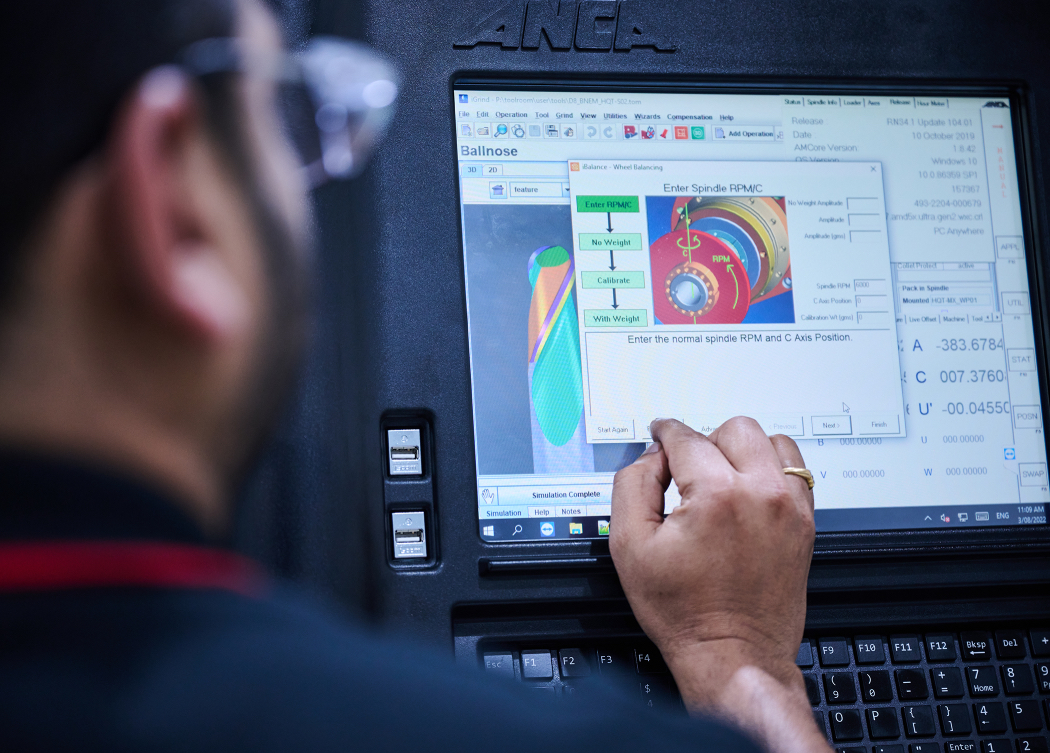

Tool and wheel performance can be further optimised by the iBalance software, which guides a user to the optimal grinding position and RPM for vibration monitoring and balancing the wheelpack inside the machine. Correctly balanced wheelpacks result in superior surface finish and reduced wheel wear due to the elimination of wheel vibration.

Consistency in finished tool quality:

A major inclusion in the MX7 ULTRA package is the total tool runout measurement and compensation operation in iGrind. When an endmill is in rotation it is important that each tooth hits at the exact same spot along the workpiece for longer tool life and efficient cutting. Every tool in the batch can be measured and compensated for runout to make sure the entire batch is within a tolerance of 0.002mm. It is another piece of assurance that the first endmill will be as good as the last.

Consistent spindle thermal stability:

Motor Temperature Control (MTC) is a patent pending innovation built into the motor spindle drive firmware. Smart control algorithm actively manages and maintains the temperature of motorised spindles in the MX7 ULTRA. Dramatically reduced machine warmup time means production can start sooner, once the machine has reached thermal stability. This improves productivity and machine use. Consistent thermal stability of the spindle over time regardless of changes in load or speed, or coolant temperature, greatly improves the dimensional stability of grinding results.

Post grinding processes:

The smoother, finer cutting edge and surface finish as a result of the combination of all the above including the nanometre control will assist in all post grinding applications like edge preparation and coating. A finer edge that has been properly prepared has greater stability, which reduces the likelihood of it chipping, while also decreasing surface roughness which can cause increased friction between the tool and the workpiece.

More Information

Related Product

ANCA’s New Era of Automation: Intelligent Solutions for Maximizing Productivity 24/7

ANCA’s launch of integrated solutions with AIMS, connects sequential processes in tool manufacturing, to bank the benefits of automation and integration. AIMS facilitates streamlined tool production, linking separate processes to each other and factory IT systems. The future of toolmaking is here, with AIMS providing versatile, modular options for common manufacturing challenges to optimise cutting tool production.