ABB, Imperial College London and Unleash Live Leverage AI-Powered Video Analytics in the Control Room

June 19, 2024

- Part of the carbon capture pilot plant at Imperial College London, the project adds AI-powered video analytics to a suite of technologies used in the control room

- The project will explore how AI-powered video analytics can provide actionable insights to plant operators to drive safety, productivity and efficiency

- The pilot plant provides the engineers and scientists of the future with hands-on experience of the use of technology

ABB, Imperial College London and innovative computer vision company Unleash live will leverage AI-powered video analytics in a new project that aims to help industrial companies improve safety, productivity and efficiency.

The project will explore ways AI-powered video analytics can amplify human potential and help to avoid human errors in industrial plants. It is part of the carbon capture pilot plant at Imperial College London, the only teaching facility of its kind in the world. The plant uses the ABB Ability™ System 800xA® for distributed process control and over 250 ABB instruments measuring temperature, pressure, carbon dioxide and flow to train the engineers and scientists of the future.

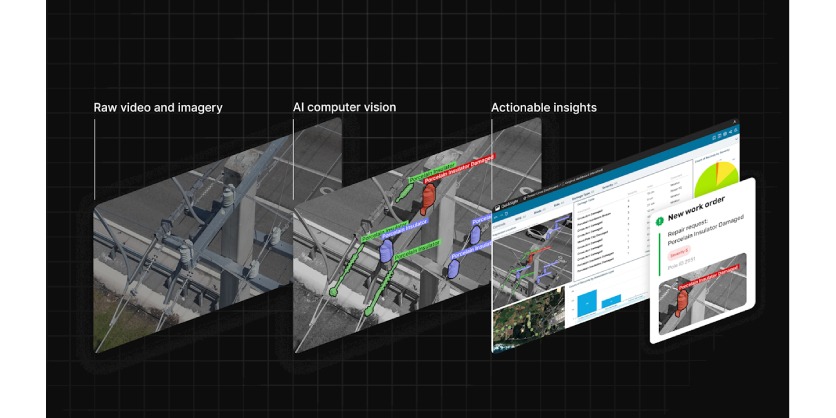

The control system of the carbon capture pilot plant automatically controls and coordinates all aspects of the plant process, which is then visualized on displays where the students can monitor and intervene if necessary. As part of the new project, AI will track video images received through an ABB Ability™ System 800xA plug-in which alerts the control system if instrumentation is not positioned correctly before a process is started or shut down. For example, it will determine if selected valves are in the correct position – open or closed – before pumps shut down. It can also detect unusual events such as smoke or fire, or health, safety and environment related events, such as the lack of protective equipment on workers.

“We have many analytical technologies in our portfolio, and we are now very keen to explore the full potential of AI-powered video analytics,” said Jean-René Roy, Global Business Line Manager, ABB Measurement & Analytics. “A great deal of operational insights can be extracted from images, and it is great to see that innovation is ripe in this space. We want to foster collaboration and knowledge exchange between industry leaders, startups and academic institutions to address key industrial challenges.”

“On a big industrial plant, you may have security cameras and other types of camera networks, for example CCTV,” said Hanno Blankenstein, CEO Unleash live. “AI-powered video analytics allows you to send video feeds from the camera system to the operator workspace and provide actionable insights in real-time, something that otherwise may take hours. This capability is underutilized, and we want to show its potential.“

Unleash live is an innovative enterprise that combines computer vision technology with real-time data analysis with the goal of equipping industries with actionable insights. In 2022, Unleash live won ABB Measurement & Analytics’ Startup Challenge. The aim of the challenge was to identify digital imaging technology that could complement ABB’s analyzer portfolio, helping customers to improve safety, productivity and efficiency.

In 2023, ABB and Imperial College London signed a 10-year contract to extend their successful partnership. More than 4,500 students have had hands-on experience of ABB’s technology solutions at the plant since it opened in 2012. The collaboration gives the university access to some of the most advanced control and instrumentation technology available from any manufacturer. Undergraduate students at Imperial College London were involved in the development and testing of the use cases in the new project.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Related Story

A Review of ABB’s “Billions of Better Decisions”

ABB recently hosted Billions of Better Decisions – Empowering the Workforce with the Industrial Internet of Things, a panel moderated by Molly Wood, Climate Investor and Journalist, and Managing Director of Launch. There she interviewed three industry experts: Peter Terwiesch, President of Process Automation at ABB, Ahmed Hashmi, Senior Vice President, Digital at bp, and Michael Wade, Professor of Innovation and Strategy and Director of Global Centre for Digital Business Transformation at IMD.