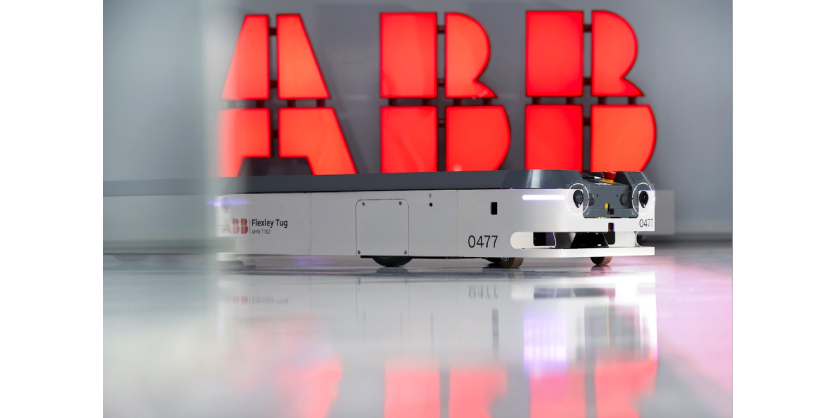

ABB Acquires Sevensense, Expanding Leadership in Next-Generation AI-Enabled Mobile Robotics

January 11, 2024

- Swiss start-up Sevensense, a leader in AI-based navigation, enables the highest levels of speed, accuracy and autonomy of mobile robots, one of the fastest growing robotics markets

- Acquisition underlines ABB’s strategic investment focus on innovative AI solutions transforming industries, such as logistics and manufacturing

- ABB becomes leader in next-generation AMRs, integrating Visual SLAM technology with leading hardware and software portfolio

ABB has announced that it has acquired Swiss start-up Sevensense, a leading provider of AI-enabled 3D vision navigation technology for autonomous mobile robots (AMRs). Sevensense was founded in 2018 as a spin-off from Swiss technical University, ETH Zurich.

“This marks a significant step towards our vision of a workplace where AI-enabled robots assist people, addressing our customers’ needs for greater flexibility and intelligence amidst critical skilled labor shortages,” said Sami Atiya, President of ABB Robotics and Discrete Automation. “Each mobile robot, equipped with vision and AI, scans a unique part of the building; collectively these robots complement each other’s view to form a complete map, enabling them to work autonomously in a rapidly changing environment.”

Sami Atiya, President of ABB Robotics and Discrete Automation

The acquisition follows ABB’s minority investment in Sevensense after it joined the company’s innovation ecosystem in 2021, the same year ABB acquired ASTI Mobile Robotics. Financial details of the transaction were not disclosed. Following pilot customer projects in the automotive and logistics industries, ABB will integrate Sevensense’s technology into the company’s AMR portfolio, offering an unprecedented combination of speed, accuracy, and payload.

The market for mobile robots is expected to grow at 20 percent CAGR through 2026, from $5.5bn to $9.5bn and ABB’s AI-powered 3D vision technology is at the forefront of this growth.1

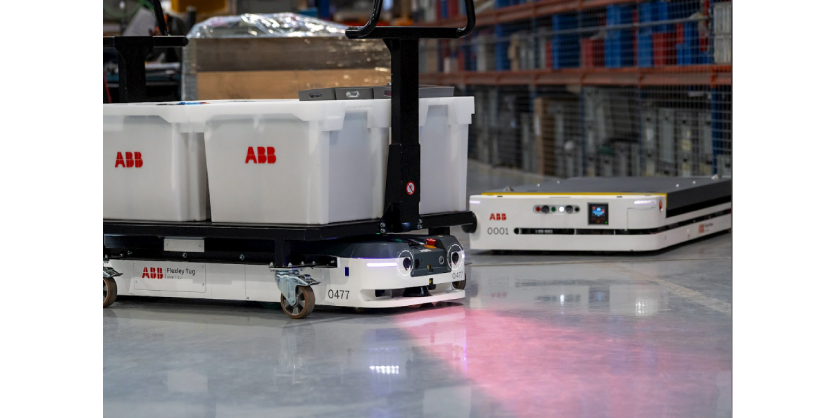

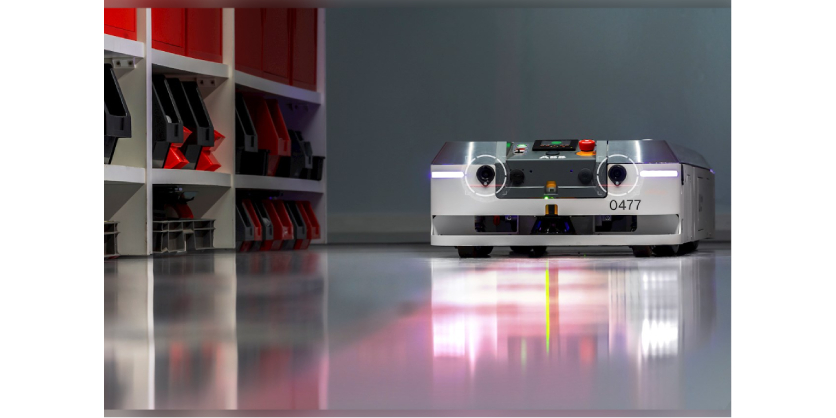

Sevensense’s pioneering navigation technology combines AI and 3D vision, enabling AMRs to make intelligent decisions, differentiating between fixed and mobile objects in dynamic environments. Once manually guided, mobile robots with Visual Simultaneous Localization and Mapping (Visual SLAM) technology create a map that is used to operate independently, reducing commissioning time from weeks to days and enabling the AMRs to navigate in highly complex, dynamic environments alongside people. Maps are constantly updated and shared across the fleet, offering instant scalability without interrupting operations and greater flexibility compared to other navigation technologies.

Today, this AI-enabled navigation technology is already transforming the automotive manufacturing and logistics sectors, delivering value through faster and more efficient operations. For automotive manufacturer Ford, Visual SLAM enabled ABB AMR’s will create efficiency gains in production sites in the US, while Michelin will use the technology in intralogistics at its factory in Spain. Other automotive manufacturers will roll out the technology in the UK, Finland and Germany.

“Offering more autonomy and cognitive intelligence, ABB’s unique market-proven technology paves the way for a shift from linear production lines to dynamic networks. Intelligent AMRs autonomously navigate to production cells, tracking stock inventory as they go and sharing this information with other robots, while collaborating safely side-by-side with humans,” said Marc Segura, President of ABB’s Robotics Division. “With the acquisition of Sevensense, ABB becomes the leader in next-generation AMRs, offering Visual SLAM in Autonomous Mobile Robots, together with an integrated portfolio covering robots and machine automation solutions, all managed by our value-creating software.”

Marc Segura, President of ABB’s Robotics Division

Gregory Hitz, CEO of Sevensense, said: “This is a significant moment in our shared journey, as we introduce our home-grown technology to a wider range of markets and sectors. ABB is the ideal home for us to continue scaling our versatile platform for 3D visual autonomy, serving OEMs across the automated material handling and service robotics industries. Together, we will redefine the limits of AI-enabled robotics.”

This revolutionary technology has the potential to impact robotics far beyond AMRs, leading to greater efficiency, flexibility and accuracy throughout production and intralogistics. The technology will also continue to be sold across segments including material handling, cleaning and other service robotics fields under the product name Sevensense.

The Sevensense partnership highlights the success of ABB’s commitment to nurturing the next generation of innovations. Through its partner ecosystem and collaboration with start-ups and universities, ABB develops leading technology for the benefit of global businesses. Sevensense’s approximately 35 employees will continue to be based at its Swiss office in Zurich.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered, and operated. Building on more than 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Endnotes

- ABB analysis

Related Story

ABB Partners With Start-up Sevensense to Drive Next Generation Autonomous Mobile Robots

ABB is entering into a strategic partnership with Swiss-based start-up Sevensense, founded in 2018 as a spin-off from ETH Zurich, to enhance ABB’s new autonomous mobile robotics (AMR) offering with artificial intelligence (AI) and 3D vision mapping technology. The technology will offer customers unprecedented levels of flexibility as mobile robots will be able to navigate autonomously in complex, dynamic indoor and outdoor environments close to people.