Xaba Inc. Gives Cognition to Machines, Disrupts Industries with Quantum Leap for Intelligent Automation

July 3, 2024

By Krystie Johnston

Massimiliano Moruzzi, CEO of Xaba Inc. is an Aerospace Engineer whose innovations have impacted products and solutions for leading companies in aerospace, automotive, and energy. Xaba Inc. recently won the 2024 ABB Startup Challenge that asked companies around the world to present their solutions that will make an impact on the energy transition by leveraging artificial intelligence. Moruzzi discusses the disruptive technology that won and why it is time to change the way industrial automation is approached.

Originally from Milan, Italy, Moruzzi has spent the last two decades in North America, earning degrees in the United States in Artificial Intelligence (AI) and AI-Applications for Robotic Systems, and working on innovative projects such as Boeing’s Dreamliner 787 and Project Arrow. Moruzzi’s passion for innovation and invention has significantly impacted these industries. Currently, he is focusing this passion on the industrial automation space where he is disrupting the industry with a synthetic brain he calls ‘xCognition’.

Intelligent automation enabling a world of sustainable manufacturing

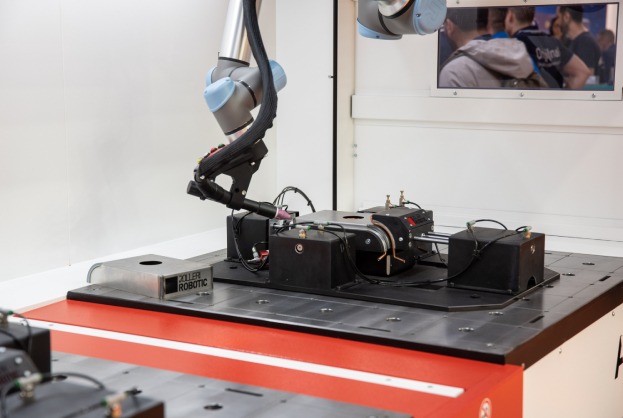

Moruzzi believes that cognition can be introduced into a machine (i.e., a robot, a CNC, etc.), allowing it to ‘think’ for itself – the way a human does – and can eliminate complicated programming, freeing machines and humans simultaneously. This idea is disruptive because it challenges how industrial automation has been approached since the first programmable robot was introduced in the 1950’s.

However uncomfortable it may be, Moruzzi says this disruption is necessary to really achieve automation. Current automation practices are becoming archaic, and with the maturation of AI, they are poised for a quantum leap forward that Xaba is prepared to catalyze.

In the current landscape in industrial automation, companies spend a lot of time adopting robotics into their operations. Moruzzi says he has seen it take hours, weeks, months, even years, for a robot to complete the task it was purchased for – and to do it correctly. He sees companies searching for new solutions, only to end up with the same result.

“So, we created Xaba to really say, ‘Hey, what is missing in the automation is not another hardware. It is the brain. The machine does not have the brain. So how can you talk with something that does not understand? And pretend that it does the thing [task] right? When it is not even equipped with what it needs in the first place to really create what automation is?”

Today’s robotic systems lack intelligence and precision

Automation is the application of technology, programs, robotics, and processes to achieve their outcomes with minimal human input. Moruzzi says that what we have today is iterations and iterations of a mechanization that in fact requires significant human supervision. What is needed to achieve automation is to introduce intelligence in a way never dreamed of that will liberate both machines and humans.

In fact, he called the company Xaba because it means something like, “Imagine dreaming and transforming that dream into a reality,” and is the catalyst that will help the automation industry take the quantum leap it is ripe for.

“There is a big gap both in the design and the mentality of how design is approached, where in essence, you are not approaching the design by really trying to solve the problem that is presented to you. You are tackling it with the arrogance to have a solution immediately. At best, what we have in front of us today is an iteration of two or three different processes. And sometimes with humungous limitations in what the definition of the problem is, so that later, there are repercussions because it is not efficient, not sustainable, or it is not really matching the requirements for which it was done.”

Moruzzi continually sees the pain points companies face integrating robotics and contextualizes them into two common challenges he sees: 1) programming the machine to do a specific task, and 2) the discrepancies between who supplies the machine for the automation.

He says it is astonishing to see companies – major companies – who struggle to do a simple registration of a part. Or communicate where an object is located compared to a machine. “They are still using ancient procedures. It is so rudimental. The amount of time they are wasting, the defects that they are creating there, is something that astonished me,” Moruzzi says.

“The other thing is that you have a discrepancy between who is delivering equipment for the automation, for example, the original equipment manufacturers in the robotics and machine introductory, and the fact that there is such a gap between the hardware versus this is what the hardware needs to do. I see companies spending months or years, constantly retooling, reprogramming – and supervising this.”

Automation is expensive to adopt and deploy

Xaba was created to help mend these pain points; Moruzzi saw humungous business opportunity in solving these challenges. But he also saw a lack of opportunity as well for people, for humans, to be augmented as they should. And this is the prime reason why he founded Xaba.

“Right now, manufacturing is perceived like a job – not a career. And there is a humungous difference between the two. That is why a company has a hard time hiring a worker or a machinist, because it is not a career anymore, at least not for everyone, not the majority. They do not see that occupation as a career,” he explains. When AI combines with the machine, a job can become a career again.

The concept of Xaba’s xCognition is genius. Moruzzi explains that a human brain has two parts: 1) the cerebellum (which he refers to as ‘the deep part of the brain), and 2) the cerebrum (which he refers to as ‘the cortex’). For the purposes of understating Xaba’s synthetic brain concept, this article will simplify that the functions of the cerebellum are to coordinate muscles movements, maintain posture, and balance. And the function of the cerebrum is to perform higher functions, like interpreting touch, vision and hearing, as well as speech, reasoning, emotions, learning, and fine control of movement1.

At Xaba, Moruzzi has created a synthetic version of these anatomical parts. For instance, once a machine is running xCognition on top, it has the deep part of the brain that controls the movements of the machine. But in this case, it is not bones, muscles, and skin, it is the mechanical components of the machine, controlled by EtherCAT, PROFINET, PROFIBUS, and other electric wires.

And the cortex of the brain consists of complex algorithms and proprietary systems and intellectual property that serve as the reasoning and higher functions indicative of the cerebrum in a human. In essence, xCognition makes a machine capable of taking instructions, understanding them, and generating an action that can complete the task.

Xaba develops new processes, control systems and materials that make automation accessible and affordable

With xCognition, Xaba has created a synthetic brain for any robot, any machine essentially. Moruzzi explains, “There are two big builders inside it as conditions for this synthetic brain that we are developing at Xaba. One is a ‘Physics-Based Machine Learning Model’ that replicates the elasto-mechanical dynamics (the physics) of any machine. We started with a robot, but the model is expandable to any other configuration of the machine.

We developed a deep, artificial neural network representation of the physics of the machine. What this means is that we are correcting for gravity, elasticity, friction, transmission, weight, and so on. Number one, I had to build the deep side of the brain, because without that one, the cortex would have communicated with something that has no value.”

Moruzzi continues, “The second one is the cortex. This is proprietary. I call it ‘Rule-Based Language System’. So, it is not like ChatGPT or Large Language Models (LLMs) for several reasons. You can ask ChatGPT, for example, ‘Can you generate an example of a program to move a de facto from A to B?’ You can go to ChatGPT multiple times, and you will get a sequence of instructions that you can try to send to the robot. In some situations, it gives you an error, in other situations, it executes some tasks. Now, is the task correct? Does the task have any physical meaning? Zero. Zero.”

It was imperative for Moruzzi to create something new. LLMs do not have a deep side of the brain either; they are trained by an encyclopedia and do not have knowledge of the physics of the machine in front of it. “Yes, you can learn from an encyclopedia that the syntax for an ABB robot is that one, and it can try and use that one,” Moruzzi admits.

But the problem with using this language system is that the instructions only work if that ABB robot is in the exact environment that was presented in the encyclopedia. The moment that robot is presented with a new environment and tries to complete the task it has learned from the encyclopedia, it will fail.

xCognition works with both old and new robotic systems and all robotics OEMs

There is one more component of the brain that Moruzzi needed to create to round off his synthetic brain and introduce cognition into machines. It is this component that ensures this disruption to the industry does not isolate Xaba in an ivory tour or silo its technologies. “The third one is a universal transponder, to be sure that the brain is completely agnostic to the output. What that means is that today, we can work with KUKA, we can work with ABB, we can work with FANUC, we can work with YASKAWA, whatever you want, we can work with all of them. Why? Because I wanted to enable a transfer of learning among the machines.”

Moruzzi has visited many companies and has seen all too often that they use different types of machines. It is never just one. And he has witnessed the nightmare it can be when a company wants to transfer a job from one machine to another. His vision for Xaba is to build a world of sustainable manufacturing enabled by the next generation of intelligent automation. Today, Xaba has created two incredible, unique components in the arena of industrial AI. These achievements are the result of investing in the ontology of the data.

“What does that mean? Today, you need a lot of data. In the world of industrial AI or strong AI, it is not the question of having a lot of data. It is adding data that is properly curated, labeled in a way that an algorithm, a network, a neural network, can truly learn and synthesize the problems that you are trying to teach to the network. Industrial AI that we develop is not de facto recognition into the data. It is not that. It has to learn,” says Moruzzi.

Ontology is a branch of metaphysics that deals with the nature of being. Using an example, he says a machine needs to learn that it has X number of limbs, and the different ways each limb can move. Making this a reality is incredible. “We had to develop an ontology structure in a way that was possible to train a neural network about the physical problem, like the last two mechanical, dynamical problems,” he adds.

Automated program generation and AI-powered calibration for accuracy and precision

Xaba’s xCognition is ready today. Moruzzi says that Xaba delivers ‘brain training’ for every machine. “We spend one to two days collecting data using special equipment that we run on top of the machine in a way that our deep side into the brain learns about that. And when they deploy the solution. Really, the machine follows the trajectory it should, works as it should.”

He adds that xCognition can enable to robot to do operations that were impossible before, because the solution opens the robot or machine to determine its own trajectories and set its own tolerances, rather than follow a single point like it was designed to do for the last decade. “We are really opening up this year,” says Moruzzi.

What is next for Xaba is to disrupt the control itself because its current infrastructure is a limiting factor in the next generation of intelligent automation. Moruzzi says that one of the limitations of current hardware is the control, because it is still based on PLC ladder logic.

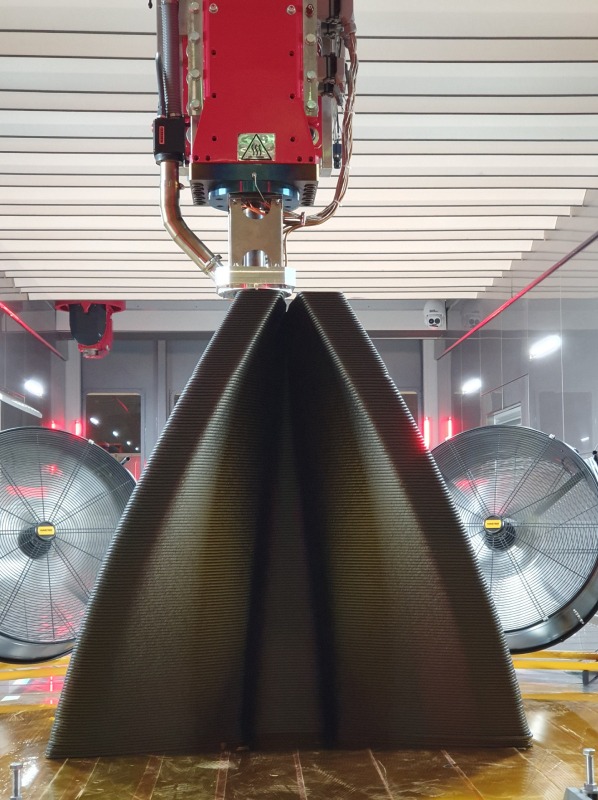

“PLC ladder logic is incapable of incorporating any AI. And if you do not have AI on top of the machine, my question is, ‘How can you ask the machine to do, for example, a functional car chassis like I did with the 3D printing? How is it possible to transfer that when it is nothing more than a sequence of lines that you have to read from a pre-computed file on a digital environment that is completely written but has no physics?’ That is why they cannot.”

Moruzzi gives another example to show how current controls are limiting the realization of intelligent automation. A robot programed on a CAD system cannot perform tasks beyond what it is programmed to do. Not without constantly adjusting the angle and the code required to achieve that, because it does not have that ‘Physics-Based Machine Learning Model’ Moruzzi mentioned earlier. Taking the PLC into a world of intelligent automation is precisely what led to Xaba’s win of ABB’s 2024 Startup Challenge.

“What we are working on with ABB is the next generation of control, where the AI, in essence, this industrial AI, our brain, produces exactly all the intelligence and logic and impacts the control with what we have never had before. So, not just the auto programming part of the task, but this web intelligence, and the capacity to control the industrial body, and the action it must do independently, with the key performance indicators the machine is required to achieve,” Moruzzi explains.

Industrial automation continues to evolve. Xaba’s introduction of AI is leading the way towards intelligent automation that will impact essentially every industry, from automotive to water and wastewater and everything in between. Xaba’s disruptive technologies are poised to make a dramatic advance on intelligent automation and enable a world of sustainable manufacturing.

More Information

Related Story

ABB Startup Challenge Winners Use AI to support the Energy Transition

Some of the most innovative startups were recognized at this year’s ABB Startup Challenge in the Sophia Antipolis technology park near Nice, France. The competition invited startups to explore how AI could be incorporated into existing energy industry platforms and systems supporting the energy transition and a low-carbon future.